11029

Post by: Ketara

I'm seeing this more and more. One company ordering a dozen Phrozen printers to churn out their components; rather than investing into silicone rubber and casting resin. Another declaring that the costs weren't too dissimilar. Are we seeing the beginning of the end of casting resin for small scale kits/components, because printers are that much more consistent, clean, or easy to operate? If not, how long will it be until they are? What do you think/know about it? Discussion people!

72249

Post by: beast_gts

I think we're approaching the tipping point. I know a few places use 3D printing for their masters then resin casting for the production (Taro Modelmaker, FW for the AT stuff).

81166

Post by: Hanskrampf

I believe so, yes.

Operating a resin printer requires different knowledge, but imo is far easier to achieve for one-man/small scale businesses.

High res master, mold making, overhangs, resin pressure, bubbles, flash, etc are all things you need to understand in order to get good casts.

Learning how to support models for resin printing, test printing and fixing the errors you made also require some work, but it's more focused.

It also doesn't require the additional storage space to store the molds safely.

The fact that you can also acquire commercial licences for models made by others and just sell them also skips the steps of hiring a sculptor or learning to sculpt yourself. A lot of them also offer pre-supported models, so then it's literally just plug&play, tending machines and post-production (curing, snipping off supports, packing them for shipping).

I'm not sure if there is a break point where it would be more viable to invest in proper resin casting than to just buy an additional printer.

11029

Post by: Ketara

Hanskrampf wrote: Hanskrampf wrote:

The fact that you can also acquire commercial licences for models made by others and just sell them also skips the steps of hiring a sculptor or learning to sculpt yourself.

That's been a really interesting development actually. Certainly not one we saw before, but which has really kicked off over the last year and a half. All the 3d sculptors are working for themselves now, because their back catalogue is something they can either directly sell prints of from a third party service, or lease to someone else to a set period of time to do it!

77922

Post by: Overread

I wonder how much difference there is in operator input when it comes to scaling things up. Small scale I suspect the costs might be approaching a point where its not dissimilar; I think the real test is how easily the system scales up. Ergo once you are no longer making a dozen a week but perhaps dozens every day to keep up with demand.

Granted with 3D you could argue that if the market expands you could offset that by selling files, however from what I can see selling files seems to work for one-man designer bands, but might not work for a group wanting to do more. Ergo making and producing a game as opposed to just casting creative projects. There's also the issue there of significantly reduced repeat sales per customer for a game system (you only get to sell a trooper once per customer).

81166

Post by: Hanskrampf

Overread wrote: Overread wrote:I wonder how much difference there is in operator input when it comes to scaling things up. Small scale I suspect the costs might be approaching a point where its not dissimilar; I think the real test is how easily the system scales up. Ergo once you are no longer making a dozen a week but perhaps dozens every day to keep up with demand.

You could always just buy another printer and double your output. Timing them so when one is finished you can instantly post-process and when you're finished, the other printer is finished, keeping you rotating duties. Of course, this has a limit, but it depends on the print time and number of printers.  Overread wrote: Overread wrote: There's also the issue there of significantly reduced repeat sales per customer for a game system (you only get to sell a trooper once per customer).

I don't think that's a problem. Most businesses start as as gamers taking time to dedicate into the side-project of selling minis. One-man businesses are not quitting their day-job, small scale seem to be doing fine and even large scale like Reaper seem to have no problem without a game system and monopose models only.

11029

Post by: Ketara

Hanskrampf wrote: Hanskrampf wrote:

Learning how to support models for resin printing, test printing and fixing the errors you made also require some work, but it's more focused.

It just occurred to me that on top of the above, you also don't have the costs tied up in inventory. You make what you need as its ordered. Not only does this reduce storage space, it also cuts down staff costs; as you're only ever producing what's already been paid for. You never have to shuffle stock on at cut prices to claw some money back, or sit there and watch thousands of dollars of resin be tied up in product that might take two years to move. The risk of business is consequently much, much lower. Once the initial machinery investment has been made, the only real variable is the staff cost, and staff can always be hired/fired to meet demand.

A pressure pot/vaccuum chamber can turn over product more quickly than a printer (which usually work at 3-4 hour even on current models per print). But the savings involved in running costs would seem to be significant. No over-production, lower staffing, and no storage mean you can run a reasonably sized operation out of just two rooms (an office/packing room, and a print room).

77922

Post by: Overread

I wonder if size will be a factor - ergo smaller infantry models by the printer and larger models by the casting? Assuming that larger models will take considerably longer to print.

As for order volume I'd assume any firm going into production would eventually need to shift from production to order to one that holds stock so that they can maximise delivery times. Using slower ordering times to produce an excess so that you can keep up with demand.

7075

Post by: chaos0xomega

I myself about to invest heavily into a small resin print farm for my terrain business. The key tech enabling the shift over to resin printers at the moment is the mono 4k screen - the screen provides superior print quality and significantly faster print speeds over older printers, and the increased screen lifetime means that you drastically reduce ownership and maintenance/operating costs as well.

Ketara's print-to-order model is the dream, but you need a significant print farm to enable that if you have a steady order/sales volume. My larger pieces run about a 4-5 hour print on the faster mono 4k printers out there, not including post-processing. If I'm just getting one-off orders for one or two pieces a couple times a day average, 2-3 printers is enough to keep up with demand easily. If I'm getting orders for multiple pieces or sets of stuff, then those printers might be tied up for a few days just to print out that one order (especially once you factor in that I can't continuously man those printers because I need to sleep and go to my day job, so theres a built in dowtime when the printers are idle and I can't reset a print - if I set a print when I go to bed, figure I lose 2-3 hours between completion and me waking up unless I stay up a bit later, and then if I set one before I leave for work figure another 5 hours lost before I'm home to restart again.Realistically I would figure the ability to print for about 15 hours per day max unless I bring in help to keep things running around the clock).

11029

Post by: Ketara

Overread wrote: Overread wrote:I wonder if size will be a factor - ergo smaller infantry models by the printer and larger models by the casting? Assuming that larger models will take considerably longer to print.

I think that depends on the model/skill of the designer. You see a lot of .stl files from the odd new sculptor which, frankly, are poorly designed for printing. Thin pieces, huge awkward sections, and so forth.

If you compare that with say, Maker Cults Isopodius:-

It's cut up in a similar fashion to what you'd do with a sculpt optimised for resin printing. But in doing so, you can assemble all the different bits on the build plate as easily as you can for a smaller model. Unless you're making something outside the size range of even the largest build plates, there's no real difference if the sculptor does their job well at the start.

As for order volume I'd assume any firm going into production would eventually need to shift from production to order to one that holds stock so that they can maximise delivery times. Using slower ordering times to produce an excess so that you can keep up with demand.

I'm not sure that's entirely true or false and is quite situation dependent. I accept that it certainly applies to resin cast, but if you have sufficient printers, you can cope with meeting just about any level of demand within a predictable set time frame. Resin casting requires more in the way of skilled staff to produce tending at best two or three stations at a time. Printing, assuming its been pre-optimised, tested, and worked out in advance, is largely a case of clicking a button and then scraping the result into a clean/cure station. One bloke should consequently be able to tend three or four times the output in those situations (note the emphasis on 'pre-optimised and tested' - I know that new models require much more work and test prints).

If your production rate is that much more flexible, any advantage accrued from producing without orders is paralleled by excess staffing costs and cash tied up in static product. You'd consequently probably be better off just buying extra printers with the money which would otherwise be tied up, and having a handful of part-time staff on zero-hour contracts.

I suppose what I'm saying is that I'm not sure which side has the advantage, but it's certainly not clear cut.

Automatically Appended Next Post:

chaos0xomega wrote:I myself about to invest heavily into a small resin print farm for my terrain business. The key tech enabling the shift over to resin printers at the moment is the mono 4k screen - the screen provides superior print quality and significantly faster print speeds over older printers, and the increased screen lifetime means that you drastically reduce ownership and maintenance/operating costs as well.

That's really cool! What printer models have you settled on and why? Also, what's the business name? Give me a plug!

Ketara's print-to-order model is the dream, but you need a significant print farm to enable that if you have a steady order/sales volume. My larger pieces run about a 4-5 hour print on the faster mono 4k printers out there, not including post-processing. If I'm just getting one-off orders for one or two pieces a couple times a day average, 2-3 printers is enough to keep up with demand easily. If I'm getting orders for multiple pieces or sets of stuff, then those printers might be tied up for a few days just to print out that one order (especially once you factor in that I can't continuously man those printers because I need to sleep and go to my day job, so theres a built in dowtime when the printers are idle and I can't reset a print - if I set a print when I go to bed, figure I lose 2-3 hours between completion and me waking up unless I stay up a bit later, and then if I set one before I leave for work figure another 5 hours lost before I'm home to restart again.Realistically I would figure the ability to print for about 15 hours per day max unless I bring in help to keep things running around the clock).

See, you're running it as a part-time job in your own hours running solo. I'm envisioning it on more of an industrial scale (say, two dozen printers and a couple of full-time staff). Sounds to me like you're working in that direction though! It's all so new that I think the optimised model still needs to be worked out to a degree. But I reckon once it's done, it may well edge out resin casting. What do you think?

7075

Post by: chaos0xomega

That's really cool! What printer models have you settled on and why? Also, what's the business name? Give me a plug!

Right now it looks like I'm between the Photon Mono X and the Elegoo Saturn. I like the look/sound of the Phrozen Sonic XL 4k but I am struggling to find any real "in the field" reviews or info about them (I don't watch youtube videos, so if there are video reviews I'm completely unaware of them), and its a bit hard to justify the price on them unless their performance really is what Phrozen promises it to be without caveat (the advertised 200mm/ hr print speed seems to be because the printer allows for a very large layer height of .3mm, which is a bit misleading because the other printers in the category top out at around .15mm, obviously you can print faster if your layers are thicker). Similar can be said about the Epax e10. Between the Mono X and the Saturn I think I'm currently leaning towards the Mono X, but originally I was leaning towards the Saturn. The Mono X has a slightly larger print area (mainly in the Z axis) and seems to be more readily available at the moment and also more reliable as elegoo seems to be struggling with delays and quality issues (theres been a trend of the screens not functioning, as well as a slightly less common trend of damaged z-axis issues).

As for a plug - this account is kind of an donkey-cave and has probably earned itself a bad enough reputation in some circles that I don't want to connect it to my business publicly lol. I'll shoot you a PM.

Ketara wrote: Ketara wrote:

See, you're running it as a part-time job in your own hours running solo. I'm envisioning it on more of an industrial scale (say, two dozen printers and a couple of full-time staff). Sounds to me like you're working in that direction though! It's all so new that I think the optimised model still needs to be worked out to a degree. But I reckon once it's done, it may well edge out resin casting. What do you think?

If I was to do this at an industrial scale, I think I would be using a small number of larger industrial printers as opposed to a larger number of small hobby printers. Not only do they print faster but you can fit more in the build volume. I can fit one of my larger pieces on the bed of a printer like a Photon Mono X, Elegoo Saturn, or Phrozen Sonic XL 4K and print that in say 5 hours, but with some of these industrial printers I could fit maybe 6 or more of the same model within the build volume and print all 6 of those in about 3 hours. Sure it costs a lot more to purchase up front, but its 10x the throughput per printer. There are technologies in development currently that promise even larger build volumes and faster print times. HARP technology promises printers with volumes measured in cubic feet and vertical printing speeds of 12-18 inches per hour. I.E. You could have a 2'x2'x4' print volume that can be printed in about 3 hours. At that point I'd be printing 200-400 copies of my largest sculpt (depending on orientation, etc.) in one go, which works out to 333-666x more throughput than what is achievable at the hobby printer level - again, expensive (I've had some discussions with manufacturers working on these, they seem to be targeting "hardware as a service" business models where you lease the printer for $40-50k per year including a post-processing station, etc., which includes maintenance and servicing by the vendor, with the cost being offset against the volume of their proprietary resin you run through (to the point that if you're printing at certain volumes the printer is free and you're just paying for the resin).

38561

Post by: MDSW

When I finished the KS for my game I needed to produce about 32 games. While this does not seem like a lot, my tipping point to order a second printer was going to be 40, so I was just under the mark and decided to go forth with my one resin printer (Mars) and some items being silicone molded and cast in polyurethane.

Each game required about 11 print runs in the 3-4 hour range. What was very difficult was the time available in a day, as others have mentioned. But, the printed pieces were a real breeze compared to the cast pieces - that was my real nightmare and there was no way to 'set and forget' for any real length of time, as there was no output. Then factor in the mold degradation and subsequent clean-up required of the poly pieces, the last few I just printed them on the printer and will probably never cast in bulk again.

The 4k monochrome screens will/have revolutionized this industry and right in front of that is the resin costs and formulas becoming cheaper and more suitable for mini printing.

I did a thread in the 3D print forum about my dilemma between the Saturn and Photon big printers, as one of these will be decided upon just after the first of the year.

I have 2 new games being developed now and printing the prototypes, but will be looking to set the next KS at the level to mass produce the game and I have to do very little; however, having the capability to produce everything is a real boon for me and all gamers - just not for the industry giants.

With the quotes and knowledge of mold costs to produce overseas, the cost effective point to mass produce seemed to be around the 500 piece mark. This is certainly doable with a small print farm and hopefully new resin formulas will be developed to decrease the cost and not be so brittle.

87056

Post by: Valander

I think so, yes, and have thought this might be the way things were going for a few years. Some of the costs and tools weren't quite there, though, until very recently, and the trend is pointing towards on-demand printing being more cost effective than resin casting, I think. As others have mentioned, storage space is actually a pretty big thing (and less "dead stock" when you print on demand or for orders + a little bit), and the ability to start a print then leave it unattended, say overnight, also can help in comparison to resin casting.

Per-piece costs are getting very, very close in comparison to materials between 3d printed and resin casting (resin casting is still slightly better, even with mold amortization), but labor and storage for 3d printers is slightly better. I think as printers get even better and 3d printing resins come down in price (which they are trending; compared to 2 years ago they're *much* cheaper), it's going to be an even choice on costs for smaller businesses and low-run production.

The best cost per piece are of course injection molded, but for that you need to know you'll have a *huge* volume in order to make up the much more expensive mold costs. Which is something most boutique/small producers just aren't ever going to do.

11029

Post by: Ketara

chaos0xomega wrote:

If I was to do this at an industrial scale, I think I would be using a small number of larger industrial printers as opposed to a larger number of small hobby printers. Not only do they print faster but you can fit more in the build volume.

Can't say I've ever heard of giant resin industrial printers, but they sound really interesting! What are the companies/model names?

MDSW wrote: MDSW wrote:When I finished the KS for my game I needed to produce about 32 games. While this does not seem like a lot, my tipping point to order a second printer was going to be 40, so I was just under the mark and decided to go forth with my one resin printer (Mars) and some items being silicone molded and cast in polyurethane.

Each game required about 11 print runs in the 3-4 hour range. What was very difficult was the time available in a day, as others have mentioned. But, the printed pieces were a real breeze compared to the cast pieces - that was my real nightmare and there was no way to 'set and forget' for any real length of time, as there was no output. Then factor in the mold degradation and subsequent clean-up required of the poly pieces, the last few I just printed them on the printer and will probably never cast in bulk again.

So you've already made the jump and produced your kickstarter using printers? What was the kickstarter and what printer models did you use? I find it really interesting that you found it to be so much easier from production angle. Did you sculpt the models too, and if so, did you deliberately do it in such a way as to make them suitable for 3d printing? Or hadn't you decided how you werehandling production beforehand?

The 4k monochrome screens will/have revolutionized this industry and right in front of that is the resin costs and formulas becoming cheaper and more suitable for mini printing.

See, this seems to have been the big thing, the jump to the 3-4 hour print times. The number of people running their own Patreon or the like is suddenly flourishing.

I have 2 new games being developed now and printing the prototypes, but will be looking to set the next KS at the level to mass produce the game and I have to do very little; however, having the capability to produce everything is a real boon for me and all gamers - just not for the industry giants.

By the sounds of things, it's actually practical for your average gamer, with a few years of prep, to run a lean one-person production machine! I wonder what impact this is going to have on the wargaming market as a whole - it certainly starts making the GW kits look like their days are numbered!

87056

Post by: Valander

MDSW wrote: MDSW wrote:

Each game required about 11 print runs in the 3-4 hour range. What was very difficult was the time available in a day, as others have mentioned. But, the printed pieces were a real breeze compared to the cast pieces - that was my real nightmare and there was no way to 'set and forget' for any real length of time, as there was no output. Then factor in the mold degradation and subsequent clean-up required of the poly pieces, the last few I just printed them on the printer and will probably never cast in bulk again.

I'm not surprised at this, honestly. While I haven't yet started my own production (still working on game design and commissioning artwork and STLs), all 3d print was my plan for pretty much all the reasons you mentioned.

Since you did both, though, I'm curious if you could give any direct comparisons on the costs of the 3d printed vs. resin-cast, and even more interestingly the comparison of the durability and so on of the finished models. Seems like a lot of the 3d printer resins that I have played with thus far are pretty comparable to cast resins I've gotten from various companies, but I haven't done any break tests, and so on.

Edit: also, yeah, the larger build area printers coming out with still good resolution will likewise help the print runs required. If you can throw the entire contents of one "set" into a single build plate, for example, the productivity will definitely go up a lot compared to having to split that into several runs. Since we just saw 4k larger printers come out, which have resolutions in line with the old 2k smaller areas (though, the Phrozen Sonic Mini 4k is currently the king of resolutions even though it has a smaller build area), we probably will see another jump in resolutions (6k? 8k?) on the large format ones soon too. (6-9 months maybe?)

7075

Post by: chaos0xomega

Ketara wrote: Ketara wrote:chaos0xomega wrote:

If I was to do this at an industrial scale, I think I would be using a small number of larger industrial printers as opposed to a larger number of small hobby printers. Not only do they print faster but you can fit more in the build volume.

Can't say I've ever heard of giant resin industrial printers, but they sound really interesting! What are the companies/model names?

"Giant" may be an understatement here, LC Magna by Photocentric for example has 20x11x13.8 build volume - its giant by comparison to a Photon or Mars or Saturn I guess. Quite a few others in this size range, basically starting around ~$20k. Some industrial SLA resin printers can hit print speeds around 6-10 m/s (by comparison, most FDM printers only do ~200 mm/s) - the SystemX 600 from x3D for example can print 10 m/s in a ~23.5x23.5x15.75 inch print area, and there are larger versions of the printer from the same company as well.

Valander wrote: Valander wrote:

Edit: also, yeah, the larger build area printers coming out with still good resolution will likewise help the print runs required. If you can throw the entire contents of one "set" into a single build plate, for example, the productivity will definitely go up a lot compared to having to split that into several runs. Since we just saw 4k larger printers come out, which have resolutions in line with the old 2k smaller areas (though, the Phrozen Sonic Mini 4k is currently the king of resolutions even though it has a smaller build area), we probably will see another jump in resolutions (6k? 8k?) on the large format ones soon too. (6-9 months maybe?)

Yeah, 8k seems to be the next frontier. It seems that the cost advantages for the lcd tech used in 3d printers are largely being achieved as a result of economies of scale being driven by the television and computer monitor industries, etc. so it might be a while yet before we find 8k screens making their way into the hobbyist arena. Thus far it seems the majority of the commercially available 8k screens are in the 80-100" range, with a handful of smaller screens that are way too expensive to really be commercially viable on a widespread scale. I think we're probably 1-2 years out from really seeing the 8k standard adopted in home printers.

11029

Post by: Ketara

chaos0xomega wrote:

"Giant" may be an understatement here, LC Magna by Photocentric for example has 20x11x13.8 build volume - its giant by comparison to a Photon or Mars or Saturn I guess. Quite a few others in this size range, basically starting around ~$20k. Some industrial SLA resin printers can hit print speeds around 6-10 m/s (by comparison, most FDM printers only do ~200 mm/s) - the SystemX 600 from x3D for example can print 10 m/s in a ~23.5x23.5x15.75 inch print area, and there are larger versions of the printer from the same company as well.

Some nice models in there, but when they start at £15,000, I can't help but wonder whether it might not be better to just buy 30 Mono X's or something for the same price! I suppose it's more of a space/power issue - that many printers will cost a lot in juice; as compared to powering one printer that does the same work through a more rapid turnover. You'd need to do some serious calculations to figure out what worked best.

7075

Post by: chaos0xomega

Yep, the energy costs of 30 Mono X's vs one bigger printer are pretty sizeable in their differences. Likewise the maintenance costs - 30 mono x screens might run $1500, whereas one replacement screen for the LC Magna or similar might only be $150.

Of course, 10 Mono X's would be a more functional equivalent (still more energy usage, still probably looking at $500 in replacement screens) to the one printer, and with the pace at which 3d tech is advancing you may find yourself wanting to replace/upgrade printers every few years as the screens wear out, etc.

87056

Post by: Valander

Yeah, the cost of operations of one of the bigger machines is probably lower on average than, say, 30 smaller. Plus, easier to manage probably.

They're a much bigger investment up front, though (even with the HAAS type contracts for leasing). I think that's one of those things that any individual business can make steps towards, though: start out with a couple smaller printers for an investment of a couple thousand dollars. If business needs are going awesome and there's the demand, get one of the bigger.

I think it's that kind of flexibility right now that may give a jolt to a lot of the smaller, hopeful miniatures producers (like me!). You can get started and hone some skills with the smaller machines, maybe even get some sales and community built, and then grow with that as needed, in whichever way you deem best.

11029

Post by: Ketara

Out of curiosity, a back of the cigarette packet calculation:-

A Mono X has a build plate of 192 x 120 x 245 mm , a max print speed of 60mm p/h, and a price tag of $750.

An LC Magna has a build plate of 510 x 280 x 350mm, a print speed of 13.3 mm p/h, and a price of $20,000

Now correct me if I'm wrong, but the super expensive one is literally only about 2 1/2 times the size of the Mono and actually has a slower print speed listed. Why is it so expensive? And why on earth would you pick it? It might be a 'giant' compared to the Mono, but it seems I only need three Monos to exceed it in terms of space. What am I missing?

5269

Post by: lord_blackfang

Someone who does a 3d print monthly loot crate posted their workflow on Youtube. They run 8 Marses, 3 print runs a day, as a solo business.

81759

Post by: BaconCatBug

IIRC Neckbeardia and a few other sites already sell 3d printed models rather than resin moulded models. Automatically Appended Next Post:  Ketara wrote: Ketara wrote:Out of curiosity, a back of the cigarette packet calculation:-

A Mono X has a build plate of 192 x 120 x 245 mm , a max print speed of 60mm p/h, and a price tag of $750.

An LC Magna has a build plate of 510 x 280 x 350mm, a print speed of 13.3 mm p/h, and a price of $20,000

Now correct me if I'm wrong, but the super expensive one is literally only about 2 1/2 times the size of the Mono and actually has a slower print speed listed. Why is it so expensive? And why on earth would you pick it? It might be a 'giant' compared to the Mono, but it seems I only need three Monos to exceed it in terms of space. What am I missing?

Because if you need to print a big prototype in a single piece, you need the big printer, which requires tighter tolerances otherwise the print will drift and screw up the print. Also, don't forget that the sole reason 3d printing has exploded in recent years is because patents expired. There has been little actual RnD done on these machines.

11029

Post by: Ketara

BaconCatBug wrote: BaconCatBug wrote:Because if you need to print a big prototype in a single piece, you need the big printer, which requires tighter tolerances otherwise the print will drift and screw up the print. Also, don't forget that the sole reason 3d printing has exploded in recent years is because patents expired. There has been little actual RnD done on these machines.

Oh, for sure, when we're talking about larger more industrial pieces of printing. But when it comes to printing wargaming miniatures, the implication earlier was that these large printers printed at a considerable rate of knots above your average Mono. When I'm looking at the specs though, that's not what I'm seeing. So I'm wondering if I'm looking at the wrong models of industrial printer or if I'm missing something.

7075

Post by: chaos0xomega

Its mostly the wrong models/4k tech hasn't entirely proliferated to the industrial scale yet, in part because LCD tech is kind of a "poor mans" printing method from the point of view of those who would employ 3D printing in an industrial setting. The resolution is poorer and the build areas by default have to be smaller in order to be useful. Another part of it is that I'm not as well versed on the Industrial side of the house as I am a long way from being able to employ industrial type printers in any way shape or form.

Once 8K and 16K LCDs start becoming available you may see that change.

99

Post by: insaniak

Ketara wrote: Ketara wrote:

Now correct me if I'm wrong, but the super expensive one is literally only about 2 1/2 times the size of the Mono and actually has a slower print speed listed. Why is it so expensive? And why on earth would you pick it? It might be a 'giant' compared to the Mono, but it seems I only need three Monos to exceed it in terms of space. What am I missing?

I suspect that the size is a large (ahem) part of the difference, as the larger you make the print bed the harder it's going to be to keep it stable for accurate printing.

That larger screen on the Magna is also ultra HD, which is going to give better print resolution.

You would also need to factor in longevity, which potentially has a big impact on cost over time. If the Magna is designed for commercial use and the Mono isn't, running them both all day, every day is going to result in the Mono potentially wearing out considerably faster.

87056

Post by: Valander

Ketara wrote: Ketara wrote: BaconCatBug wrote: BaconCatBug wrote:Because if you need to print a big prototype in a single piece, you need the big printer, which requires tighter tolerances otherwise the print will drift and screw up the print. Also, don't forget that the sole reason 3d printing has exploded in recent years is because patents expired. There has been little actual RnD done on these machines.

Oh, for sure, when we're talking about larger more industrial pieces of printing. But when it comes to printing wargaming miniatures, the implication earlier was that these large printers printed at a considerable rate of knots above your average Mono. When I'm looking at the specs though, that's not what I'm seeing. So I'm wondering if I'm looking at the wrong models of industrial printer or if I'm missing something.

Part of it is with DLP/MSLA tech, the print time only depends on the height of the model. So a larger build area means you can print more models at the same time, thus reducing the average time per model.

Some digging though shows that some of those bigger printers are still either SLA, which has great resolution but print time will depend on the total volume of the print (thus knocking out the advantage of larger build areas other than for bigger items), or the couple I looked at don't have the x-y resolution that I'd consider worth it for miniatures production (E.g., the LC Magna only has an x-y of 137um, which is really bad in comparison to even the last gen desktop ones such as the Anycubic Photon, which has 47um x-y, or hilariously worse than the Phrozen Sonic Mini 4k which is at 37um).

That's part of why new 4k large format printers such as the Mono X and Saturn are pretty attractive, since the Saturn has a x-y of 50um, and with a build plate as large as it has you can print multiple models at the same time. Plus, the monochrome screens are much more efficient on top of that.

11029

Post by: Ketara

Sounds to me that, contrary to what was assumed earlier, it may actually be the case that existing large industrial 3d printers aren't actually better at volume printing for wargaming purposes just yet. The smaller printers seem to have leapt ahead, in price, print speed, and possibly quality too!

99

Post by: insaniak

Quite possibly. I would imagine that the larger printers would generally be getting used in industries where super-fine detail isn't as much of an issue, while model makers have just gone for the smaller printers.

109057

Post by: Cybtroll

I think that from a wider perspective, it's quite the opposite.

3d printing on the long run will substitute both the mass production of model (currently covered mainly by plastic) and the small runs of big pieces, special model or anything else.

Only the two extreme, meaning extreme high volume of extremely difficult to print and more "boutique" models will survive.

This is by the way exactly what happened in traditional printing market. You print at home or in the office, unless you need huge volume, special format or high quality.

518

Post by: Kid_Kyoto

moving to 3d printing

11029

Post by: Ketara

Cybtroll wrote: Cybtroll wrote:I think that from a wider perspective, it's quite the opposite.

3d printing on the long run will substitute both the mass production of model (currently covered mainly by plastic) and the small runs of big pieces, special model or anything else.

Only the two extreme, meaning extreme high volume of extremely difficult to print and more "boutique" models will survive.

This is by the way exactly what happened in traditional printing market. You print at home or in the office, unless you need huge volume, special format or high quality.

I don't think HIPS is at risk until 3d printing becomes considerably more reliable. Less failed prints and so on, at the moment it's still a hobby within a hobby. When you can buy a printer for $300 with software which is more or less plug and play, GW will need to worry, but not until then.

I suspect a decade from now however, we'll probably be at that point. We've reached the quality point, print speed point and almost the price point (say, £150 for a machine that can do the job). The 3d simplification is well under way (auto-supporting programs get better every year). The primary remaining obstacle is the actual printing itself and its vulnerability to complications (temperature, resin, vibration, etc). I suspect we're still two or three generations away from plug and play in that sense; your average 13 year old needs to be able to do it for it to knock out GW.

I suppose the argument then will become whether or not even the small producers will be knocked out alongside Games Workshop. If everyone has a printer at home, nobody needs to buy from your miniature print farm. All they need are the stl's. The only real way to defend against that is to refuse to sell the digital files. But as any member of several print communities will know, you can get a fan-sculpted .stl of just about 40K model right now if you know where to look.

If that's the case, the real value these new companies relying on digital sculpting and small print farms right now will accrue is the amassing of digital files and copyright. Their picking up printers for production won't last any longer than the rest of the 'production' industry.

518

Post by: Kid_Kyoto

It would be ironic if one day GW found itself relying on selling rules and fluff rather than models...

60720

Post by: OrlandotheTechnicoloured

Impact! miniatures is doing this to an extent, a lot of their recent chibi miniatures KS projects (and subsequent retail work) is done via direct 3D printing,

although some of their larger selling ranges (blood bowl teams) are done via traditional methods

one fact that small companies do have to consider is what happens if your 3D printers all go down at once and you can't get repairs or replacements in a timely manner. Impact! got hit with just that situation during one of their KS projects,

mostly backers were ok with it as communitcation was good, but if they'd had similar happen in a purely retail situation I suspect it could have sunk them as shoppers are less tolerant than KS backers, especially today

7075

Post by: chaos0xomega

I suspect we're still two or three generations away from plug and play in that sense; your average 13 year old needs to be able to do it for it to knock out GW.

The tech issues are 2-3 generations from being resolved maybe, but the "culture" issues are not. For home 3D printing to truly knock GW out I think it will require the adoption of DRM and "controls" (i.e. this mini can only be printed at a max layer height of xyz or better using these settings, etc.) as the current model of releasing STLs into the wild and crossing your fingers that they don't get distributed widely for free are not really how people looking to make a living in the industry will want to operate, nor do they necessarily want their work represented by prints that prioritized time and dollar savings over quality and printed an undetailed blob so they could throw it onto the table for a game with their mates.

In fact, perhaps rather contrarily, I think home 3D printing will benefit GW - it will basically create a sort of inadvertent moat around the business and IP. While people will pirate GWs designs, GWs bottom line will survive and a market for their plastic kits will continue to exist and their products will continue sell. The real risk is to GW's competitors in the industry and smaller games that will struggle to be profitable in an environment where people want to print their stuff at home because they are less willing to invest into a small game with a nonexistent playerbase and uncertain future prospects.These games tend to have smaller product ranges that are more easily sculpted by hobbyists with access to zbrush, etc. whereas GW has a ton of kits to the extent that someone releasing STLs for one unit out of what I'm guessing is around a thousand different units across all of its game lines will hurt GW significantly less than if someone released STLs for one unit out of the 5 present in a startup game. 3D printing also significantly lowers the barrier for entry into the industry for would be designers, etc. so I expect to see a huge proliferation of games competing for attention that will struggle to reach mass/market share to ever be anything but a small hobby effort.

Really, I think 3D printing is probably going to be more damaging to your local hobby shop than it is to GW or anyone else though.

3309

Post by: Flinty

Ketara wrote: Ketara wrote:

I don't think HIPS is at risk until 3d printing becomes considerably more reliable. Less failed prints and so on, at the moment it's still a hobby within a hobby. When you can buy a printer for $300 with software which is more or less plug and play, GW will need to worry, but not until then.

.

I think we're pretty close to that now.

I got the Anycubic Mono with no prior resin experience, jammed some professionally made files into the software, hit auto supports and have burned through a litre of resin with no failed prints. I would like to think I'm competent on the IT gubbinz side, but I'm by no means a genius user.

I think the real barrier to use for miniatures is the horrible chemicals currently needed. The water washable resins cut down the overall toxicity by an awful lot, however usability at the moment is pretty robust.

77922

Post by: Overread

I dunno.

When you look at home printing with a printer you can buy a really good home printer for paper for £500 or so and it will print good quality photos and documents. Then add a few more hundreds or so for binding and such and you could make your own books.

Yet its never happened. People buy cheap printers and print out their text documents, but if they want a book they buy a book; if they want photos in a frame they use a printing shop or online printing firm etc...

If their printer runs out of ink they call support; if they run out of toner or need the heads cleaning etc... again its more hassle and problems.

I don't see the miniature market, which is very quality control picky; advancing into home 3D printing as a standard practice. I can't see GW pushing you to buy a several £100 printer to get started. Yes the long term costs might be cheaper, but the startup is WAY more expensive. Plus you've got a whole slew of skills and technical aspects in using the printer.

Nothing is impossible to learn, but I just don't see the market heading that way. Certainly not until there are some iron tight DRM systems in place and some means of really "no brains super simple home printing" systems. Perhaps in the future but not in the near future.

The DRM is also essential for any business that want's it to be a business not just a side earner. At which point one might find that the price per model isn't actually that much lower.

If anything the market that might pick it up faster is the DnD market where quality of model is less important than simply having a billion different models to mess around with - some of which might get used once or never.

4003

Post by: Nurglitch

I've had some good results having a friend print stuff for me, but I think enviously of GW plastics every time I have to chip a resin print out of its matrix of supports.

I've been giving it some thought lately about selling prints-on-demand, but then I spend time prepping resin printed miniatures and I worry that people will be unsatisfied with the printed miniatures given the hassle of removing supports.

11029

Post by: Ketara

chaos0xomega wrote:

The tech issues are 2-3 generations from being resolved maybe, but the "culture" issues are not. For home 3D printing to truly knock GW out I think it will require the adoption of DRM and "controls" (i.e. this mini can only be printed at a max layer height of xyz or better using these settings, etc.) as the current model of releasing STLs into the wild and crossing your fingers that they don't get distributed widely for free are not really how people looking to make a living in the industry will want to operate, nor do they necessarily want their work represented by prints that prioritized time and dollar savings over quality and printed an undetailed blob so they could throw it onto the table for a game with their mates.

I'm sure Games Workship can bring 'Games Workshop Slicer TM' which is the only accredited software program to open '. gw' digital files and includes DRM and manipulation limits. Sure, they can do that. And then three weeks later, someone will release a file convertor and a pirated torrent of it.

That battle has been lost by every single music, video game, film, and telly series company in existence; all of whom had much deeper pockets and incentive than GW. The more awkward you make the DRM and other restrictions, the more of your playerbase will migrate to the pirated version. The only way to 'win' that battle is to make the product cheap and accessible enough that 95% of your would be customers can't be bothered to learn how to bit torrent.

In fact, perhaps rather contrarily, I think home 3D printing will benefit GW - it will basically create a sort of inadvertent moat around the business and IP. While people will pirate GWs designs, GWs bottom line will survive and a market for their plastic kits will continue to exist and their products will continue sell. The real risk is to GW's competitors in the industry and smaller games that will struggle to be profitable in an environment where people want to print their stuff at home because they are less willing to invest into a small game with a nonexistent playerbase and uncertain future prospects.

See again, I'm not sure I'd agree with that. If modern games sites (Steam, Epicgames, etc) and streaming apps have shown, people prize both convenience and variety. Sure, Games Workshop might insist on their own platform. Let's say I can buy a multipart digital GW Ork Boyz Kit TM for £40 on their site. I then open up a Steam equivalent for models (there a few CGTrader, MMF, etc - one will become dominant in the end), and see an equally good kit from Kromlech for £15, Mantic for £12, and so on. Why would I ever stick around with GW when the variety and value is on the other platform?

I don't need GW's retail shops anymore to buy the goods. I don't need GW's factory to produce them. The only valuable things left are the playing space (which I can do at a club/home/friends house) and the IP. But if I'm not playing in their store, I certainly won't care if I'm using GW trademarked Ork Boyz or identical looking 3rd party ones (any more than I do now).

I suspect that what we might see is a real disconnect between IP and models when anyone can make a 'counts as' and throw it on a Steam equivalent platform (when 3d printers have made the technological advances discussed above of course, that is). GW prides itself on manufacturing models, not rules or lore. That may have to change.

Automatically Appended Next Post:

Overread wrote: Overread wrote:

Nothing is impossible to learn, but I just don't see the market heading that way. Certainly not until there are some iron tight DRM systems in place and some means of really "no brains super simple home printing" systems. Perhaps in the future but not in the near future.

I can brew beer at home using a home brewing kit, but beer drinkers don't do it as a rule. Likewise, it is important to note that 'printing' was never necessarily any more of a hobby than consuming alcohol, and it has never really been able to hit the convenience mark. Books survived not because people can't print them, but because digital book files weren't really a thing till e-readers came along, and because the standard print format (A4) is large, clunky, and awkward. Not to mention that ink costs are high enough. And not many people pride their personal handicraft on making books.

Frankly, I'd say that there are sufficient important factors separating them that it's not much of a comparison at all. Sorry to disagree! Automatically Appended Next Post:  Flinty wrote: Flinty wrote:

I think the real barrier to use for miniatures is the horrible chemicals currently needed. The water washable resins cut down the overall toxicity by an awful lot, however usability at the moment is pretty robust.

That's a solid factor in refining the design. What you want is (ironically enough considering the print discussion above) some form of cartridge system where little Timmy can just swap them in and out with minimal hassle and the resin is never loose.

38561

Post by: MDSW

chaos0xomega wrote:

MDSW wrote: MDSW wrote:When I finished the KS for my game I needed to produce about 32 games. While this does not seem like a lot, my tipping point to order a second printer was going to be 40, so I was just under the mark and decided to go forth with my one resin printer (Mars) and some items being silicone molded and cast in polyurethane.

Each game required about 11 print runs in the 3-4 hour range. What was very difficult was the time available in a day, as others have mentioned. But, the printed pieces were a real breeze compared to the cast pieces - that was my real nightmare and there was no way to 'set and forget' for any real length of time, as there was no output. Then factor in the mold degradation and subsequent clean-up required of the poly pieces, the last few I just printed them on the printer and will probably never cast in bulk again.

So you've already made the jump and produced your kickstarter using printers? What was the kickstarter and what printer models did you use? I find it really interesting that you found it to be so much easier from production angle. Did you sculpt the models too, and if so, did you deliberately do it in such a way as to make them suitable for 3d printing? Or hadn't you decided how you were handling production beforehand?

My sig has my last KS game and you can see it had quite a few printed parts. The goal was set relatively low in order to get the game produced, all with non-commercial sculpts readily available or my own sculpts.

7075

Post by: chaos0xomega

Ketara wrote: Ketara wrote:

That battle has been lost by every single music, video game, film, and telly series company in existence; all of whom had much deeper pockets and incentive than GW. The more awkward you make the DRM and other restrictions, the more of your playerbase will migrate to the pirated version. The only way to 'win' that battle is to make the product cheap and accessible enough that 95% of your would be customers can't be bothered to learn how to bit torrent.

The flip side of that is that GW makes a kings ransom by selling people 2, 3, 4+ boxes of Intercessors at $60 a kit through independent retailers, of which you can expect about $25/kit to be profit (~$40 through its own direct sales channels). So, an intercessor kit lets say offers a profit of $50-80 per customer. If GW were to digitize, keeping in mind the file is good for UNLIMITED prints, how much do they have to charge to maintain their margin? How is that going to work in an environment where a not inconsequential number of people insist that your STL's should be free of charge entirely? How is that going to work in an environment where the majority of your customers complain that your STL files are too expensive when you are literally selling them hundreds or even thousands of files for pennies on the dollar? I struggle to imagine GW making an argument to people that a set of STLs that cost $5/file cost is justifiable when people complain that $0.03/file is too expensive.

I think the future is basically an iPrinter. The files are stored in a cloud as a proprietary encoded/encrypted file type which is then fed to your printer directly once you hit the print button. Accessing the file data and DRM stripping it would be fairly difficult at that point without special hardware built to spoof the system and capture the data being transferred to the printer.

See again, I'm not sure I'd agree with that. If modern games sites (Steam, Epicgames, etc) and streaming apps have shown, people prize both convenience and variety. Sure, Games Workshop might insist on their own platform. Let's say I can buy a multipart digital GW Ork Boyz Kit TM for £40 on their site. I then open up a Steam equivalent for models (there a few CGTrader, MMF, etc - one will become dominant in the end), and see an equally good kit from Kromlech for £15, Mantic for £12, and so on. Why would I ever stick around with GW when the variety and value is on the other platform?

Thats a bit of a race to the bottom for the designers though, isn't it? Its an unsustainable industry model at that point, those competitors will compete eachother into the ground on price while GW will continue churning out injection molded kits and enjoy the competitive-play moat its built for itself that makes it hard for people to bring in third-party minis for a game. Most of these designers are already basically making less than minimum wage as it is, these businesses won't be able to sustain salaries for these guys working in this sort of environment, let alone maintain the IPs. The fact that the "barriers for entry" are being dropped by all this also means that you see individual sculptors at these various businesses slowly starting to leave to start off on their own as a freelancer or set up their own Patreons/webshops/kickstarters, etc. Which will only serve to increase competition and exacerbate that race to the bottom.

I really think people looking at 3D printing technology and saying that GW has to go digital to survive, etc. are really not looking at the big picture here - I think right now we are seeing a content bubble as people look at 3d printing and think to themselves that its easy money, that bubble will eventually burst, 99% of the designers, shops, patreons, etc. out there are going to close up shop when they realize they could be making more money washing dishes at mcdonalds, and the amount of content and product out there will slowly dry up. The alternative is that GW, Mantic, and everyone else is basically screwed and 3D printing basically kills the industry as a cohesive entity and balkanizes everything into a chaotic landscape of small players. I don't really see a future where selling prints becomes essential to GW's survival though, i think its doomed if it comes to that.

I don't need GW's retail shops anymore to buy the goods. I don't need GW's factory to produce them. The only valuable things left are the playing space (which I can do at a club/home/friends house) and the IP. But if I'm not playing in their store, I certainly won't care if I'm using GW trademarked Ork Boyz or identical looking 3rd party ones (any more than I do now).

If GW can't sustain itself because of the presently unfavorable economics of the 3d printing industry then the IP is dead, so if you care about the IP you're basically hostage to GW's retail shops and factories in order to see the IP persevere and continue.

I suspect that what we might see is a real disconnect between IP and models when anyone can make a 'counts as' and throw it on a Steam equivalent platform (when 3d printers have made the technological advances discussed above of course, that is). GW prides itself on manufacturing models, not rules or lore. That may have to change.

I expect we will see a recalibration of IP laws to make IP more defensible in the face of the proliferation of IP theft on platforms like that - industry is lobbying certain political groups pretty hard to basically make that happen. If they succeed, I expect at some point the existing DMCA and IP protection laws being used to enforce IP rights will become insufficient for IP to truly be protected in an effective manner - I would argue we're basically already there. I suspect in the future the "platforms" will eventually be forced to pay penalties for the hosted content and will have to shift into having to pre-approve content so that the "counts as" stuff doesn't make it on there, etc. Interesting to see what happens in that arena over the next decade.

87056

Post by: Valander

I think there's two distinct business models for 3d printing/STL for wargaming.

One is the small studio, maybe individual and a couple buddies, who like doing 3d sculpting and maybe the occasional tinkering with game rules. These types will likely do "all digital" games, where you can buy a PDF of some rules and a bunch of STLs, and print out at home and do your thing. In fact, we see a few of these out there already, and there are several pretty successful Patreon type businesses that do just the STLs (with maybe a license option for others to sell their printed models).

The other is, again, a small studio, but that wants to produce their own line of models/rules without going all digital. Right now, there are a few of these companies out there doing their thing but producing models in either resin or metal (e.g., Relicblade, Twilight: Anyaral, etc.). I think these types will not necessarily want to move to all digital, since they know that will by design limit their audience to those who have access to 3d printers. But the ease/quality of doing 3d printed as production vs. resin casting may well make strides in this group.

GW is not either of those types.  I don't think companies the size of GW really has any incentive to shift to a digital only (or even digital optionally) model, honestly. Their distribution and margins are already so good, they don't need to "supplement" anything, and they likely would not want to yield any of the control over quality or IP that would inevitably come with offering digital products. (Sidenote: notice they aren't doing 40k.9 codices in ebook format anymore, likely specifically to push more people to use their app and tighten down against piracy.)

Automatically Appended Next Post: And yes, for the record, I am working on trying to be in that second group eventually.

8042

Post by: catbarf

Ketara wrote: Ketara wrote:See again, I'm not sure I'd agree with that. If modern games sites (Steam, Epicgames, etc) and streaming apps have shown, people prize both convenience and variety. Sure, Games Workshop might insist on their own platform. Let's say I can buy a multipart digital GW Ork Boyz Kit TM for £40 on their site. I then open up a Steam equivalent for models (there a few CGTrader, MMF, etc - one will become dominant in the end), and see an equally good kit from Kromlech for £15, Mantic for £12, and so on. Why would I ever stick around with GW when the variety and value is on the other platform?

I'm pretty optimistic about 3D printing, but I think you are downplaying the value of 'officialness'. Right now we have a lot of third-party companies making cheaper and/or better sculpts than GW, but they're not allowed in tournaments or GW stores, and the community as a whole seems to regard them somewhere between bootlegs and outright theft. The closer to GW's style and the cheaper they are, the more resentment there is.

GW is very careful to nurture brand loyalty. For example, I have heard people say more than once that they buy GW's hobby supplies even though they know they could get the same thing for a fraction of the price elsewhere, simply because they want to support GW. It wouldn't take much to convince those people that these 3D printed alternatives are ruining their hobby, and they ought to support GW's 'official' models.

I don't think it would invalidate 3D printing but you'd definitely see enclaves of two different attitudes- the groups where anything goes, and the groups where only GW-official stuff is tolerated.

71704

Post by: skchsan

Unless 3D printers can beat curing times for casting resins, creating master with 3D printer then moving to standard casting process is going to trump over pure 3D printer based operations.

The master-to-casting process has following advantages:

1. better QC - casting is exposed far less variable for errors (bubbles, mix ratio, etc), which can all be mitigated fairly well as long as you have the equipment for it.

2. faster turnaround - typical casting resin for miniature use has cure time of anywhere between 1 hr~4 hrs, whereas 3d print time can vary from hours to days. The faster turnaround also mitigates for potential errors since you can simply pour new batch of resin whereas bad 3d prints must be restarted.

3. better post processing - cleaning the master prior to casting is going to drastically reduce the amount of post processing you need to do to have your products ready for sale. Also, casting resins are typically fairly soft, meaning it's easier to clean up with xacto. Batch post processing for 3d prints are either going to need a acetone fume bath station (for fdm) or a lot of sand paper for resin. Either way, additional cost or time.

Then, you have to compare the con's:

-initial investment: multiple 3d printers vs. few 3d printers + mold material + optional vacuum chamber - going to run similar cost

-space requirements: similar space requirements

Is what I can think of at this time.

11029

Post by: Ketara

I'm going to reply only to this, because frankly we've drifted off topic and starting discussing a different subject; namely 'Will 3d printing replace all physical production'! So to go back on topic:-

skchsan wrote: skchsan wrote:Unless 3D printers can beat curing times for casting resins, creating master with 3D printer then moving to standard casting process is going to trump over pure 3D printer based operations.

As other people have said, it's not all about cast times. That's one small fragment of the labour pie which makes up resin casting. You have to make, replace, and store molds, you have to mix resin and place it under pressure for a set period of time whilst casting, and the whole process requires far more in the way of skill/training. 3d printing seems, after much discussion, to obviate a number of these steps. I think it highly significant that at least two people so far in thread alone, who might otherwise have been forced to subcontract resin casting out for their games, have instead chosen to print their wares directly at home.

So it's not so much 'beating the casting time' as it is 'requires less time/attention from the worker whilst casting'. It might take four hours as compared to a quick-cast resin's twenty minutes (though most would set over a few hours at least); but you spend that four hours doing other productive things rather than tending your cast.

The master-to-casting process has following advantages:

1. better QC - casting is exposed far less variable for errors (bubbles, mix ratio, etc), which can all be mitigated fairly well as long as you have the equipment for it.

A printer set up with a tried/tested print in advance is far more likely to deliver a consistent product. You've removed human error, after all.

2. faster turnaround - typical casting resin for miniature use has cure time of anywhere between 1 hr~4 hrs, whereas 3d print time can vary from hours to days. The faster turnaround also mitigates for potential errors since you can simply pour new batch of resin whereas bad 3d prints must be restarted.

We're down to four hours now for current printers. That's virtually the same minimum time as a quality resin requires to set.

Then, you have to compare the con's:

-initial investment: multiple 3d printers vs. few 3d printers + mold material + optional vacuum chamber - going to run similar cost

Printers are definitely are higher investment cost, but less than you'd think. You'd pay double to triple for a vacuum chamber/pressure pot than you would a printer. True, you can probably process two to three as many molds through that chamber, but the other production processes mentioned above all cost time/money which 3d printers do not (mold making, for example).

-space requirements: similar space requirements

3d printers store their files in a hard drive. Resin casting stores physical molds. One is a lot more space efficient than the other!

71704

Post by: skchsan

Right, I'm not saying it's cheaper to run master-cast process, just that it has higher potential yield if you're trying to run a small scale production as a business.

Now, if you're referring to 'micro-scale production' (as in, simply for personal use) as small scale, then you have a different story.

Let's say a master takes 2 hr to print, and cast resin w/ cure time of 1 hr. We are producing 10 models.

3D printer only: 2 hrs x 10 = 20 hrs

Master-to-cast: 2 hrs (master) + 5 hrs (mold making) + 1 hr x 10 = 17 hrs

Then, let's say a master takes 5 hrs to print, with the same casting resin w/ 1 hr cure time, 10 models:

3D printer only: 5 hrs x 10 = 50 hrs

Master-to-cast: 5 hrs (master) + 5 hrs (mold making) + 1 hr x 10 = 20 hrs

So in essence, master-cast route can be scaled up with relative ease (just need more master, mold & casting materials) where as 3d printer only set up will require additional machines set up each time you want to scale up.

38561

Post by: MDSW

The speed to resin printing is now getting cut by about a third with the monochrome screens hitting the low end market over the last year. This means your 30mm mini at .02 layer just went from about 6 hours to 2 hours. Plus you can set up multiple copies on the build plate.

When I was casting the parts for my game the polyurethane set very quickly - about 15-20 minutes before I could demold, but that is only one. I guess I could have made multiple molds from the master, but making molds is a real pain.

87056

Post by: Valander

MDSW wrote: MDSW wrote:The speed to resin printing is now getting cut by about a third with the monochrome screens hitting the low end market over the last year. This means your 30mm mini at .02 layer just went from about 6 hours to 2 hours. Plus you can set up multiple copies on the build plate.

When I was casting the parts for my game the polyurethane set very quickly - about 15-20 minutes before I could demold, but that is only one. I guess I could have made multiple molds from the master, but making molds is a real pain.

Plus, you have to have a place to store the molds. And the molds will eventually wear out, meaning you need to make another mold, which means you have to have a place to store the masters to make said molds.

My gut feel is that the labor involved is getting pretty close to equal for resin casting vs. 3d printing. While a print may take 2-3 hours on a newer mono screen, that 2-3 hours you can spend doing other work, such as setting up supports on new models, doing accounting, sorting orders, etc. Which for small operations is actually a pretty significant thing to be able to multi-task a little bit more, I think.

Again, I don't think we're going to see 3d printing as production for larger volumes for quite a while still. But I do think that short-run production will start seeing more and more 3d print as production. Will resin (or metal) casting ever go away entirely? Probably not. 3d printing really only works if the original sculpting is done digitally. For those shops that do hand sculpting in polymer clays/epoxy still, resin casting is still the choice for production. (Yeah, you can 3d scan, but that's not quite as mature as folks would like for the level of detail we want for minis yet.)

71704

Post by: skchsan

Speaking out of experience as former 3d print shop operator/manager:

Not saying 3d printers' haven't made leaps and bounds within the last few years, but you can't discount the fact that 3d printers and peripherals too have effective life and storage requirements when comparing to operation involving casting.

Wash & cure stations, the machine itself will take up some space.

Goods with service life would include: Vat FEP, screen

Intermediate goods would include: IPA's, filtering kit, PPE's, resins

Are the first few that comes to mind.

The set up required for small-scale 3d print farm isn't much more compact than it would be to set up a casting/3d print farm.

The worst/most labor intensive aspect of two-part molds is when you're setting the scene for the first half of the mold.

My silicon molds resided in shoe boxes and didn't take up too terrible of an amount of space. Not sure if it does anything but I kept a few desiccant packs in the boxes and I've never ran into any issue with denaturing silicone (when it gets all sticky and stuff). It's either the desiccant actually did something, or I've wear-and-teared down the mold before it can denature. If we're talking about CNC-milled metal plates for injection molds, yes, that will take up a huge amount of space. Silicon molds, not so much.

My molds lasted about 10~15 casts for fine details with many fragile parts (the wear & tear causes the mold to slip more and more, and the small fragile pieces didn't have much tolerance), where as medium/low detail molds pretty much lasted me until I forgot where I put them.

EDIT:

There are many great choices for entry, hobby grade 3d printers out there for sure. But for industrial grade 3d printers are still hefty investments. Also, for these industrial grade printers will require professional maintenance if it breaks down, which typically carries few weeks of turnaround.

And because of the rate in which 3d printing technology has been improving, I personally wouldn't feel comfortable putting down too much money on getting more than, say 4 machines, if I were to set up a new farm.

Again, I'm not saying 3d printers will never take over mold-cast process - just my two cents to think about for those interested.

11029

Post by: Ketara

What's interesting about the discussion thus far really, is that it more or less has established what I was after - namely, whether it's more practical to hand cast or 3d print. Having weighed all the factors now, it seems to be the case that the two are about equal. Both have pros and cons, but neither can really be said to be 'better' any longer.

The hand casting by resin is two or three times quicker per cast IF you have the right number of staff. That's the primary advantage it still retains. But the vaccuum chambers cost more per unit, you have to find storage for molds, and it requires much more intensive staff labour and expertise.

The 3d printer on the other hand is much simpler to operate (no resin mixing or molds), much more staff time efficient, space efficient, and offers a more guaranteed quality. It's also cheaper per unit these days to buy a printer than a vaccuum chamber/pressure pot arrangement. It will need more spare parts however (the screens primarily), and manufactures at a third of the speed.

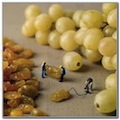

I think that more or less summarises the current state of affairs and explains why a number of small producers are choosing to go that why. Here's a picture of Reptilian Overlords print farm mid-setup.

It's pretty obviously in his basement. He's got ten Phrozens down there, along with a single cure and wash machine. One bloke on his own (there'd probably be a second wash machine if there were two of them) using a setup like that can achieve an output that frankly, would be impossible in hand cast without much larger premises. Where he would before have had to dash between his chambers/pots and spend time making molds, he can just pour some resin and click 'print' ten times. Sure, he'll have to do some washing/curing at the end of it. But if he budgets his time right, he could have one printer finishing just as he's done doing that for one batch.

Whilst the two methods could be judged equal now however, that's likely not to be the case five years from now. There is no magic form of hand casting resin which will suddenly appear. 3D print times however, may well halve, and then halve again - which would eliminate the sole remaining major advantage of hand cast. In which case, the time to set up a print farm isn't now (as you say, the current machines will likely be obsolete in short order), but in two to five years; when the advantages are so much clearer and you aren't going to waste large sums on plant which goes out of date.

82928

Post by: Albertorius

The resin itself will also improve in ease of use and lower toxicity, most probably, as time goes on, which will only help in that regards.

3309

Post by: Flinty

I think there is a benefit from getting started transitioning to printing now though because it puts you that much further into the learning curve when the next gen machines come through

Although I guess that is the benefit of using 3d printing for mastering as it combines both approaches.

Thinking of that though, one of the things above was about storage of masters. If the masters are 3d printed, then no storage is needed. When the mould fails, you just print a new master.

11029

Post by: Ketara

Flinty wrote: Flinty wrote:I think there is a benefit from getting started transitioning to printing now though because it puts you that much further into the learning curve when the next gen machines come through

Although I guess that is the benefit of using 3d printing for mastering as it combines both approaches.

Thinking of that though, one of the things above was about storage of masters. If the masters are 3d printed, then no storage is needed. When the mould fails, you just print a new master.

That actually points me to another unconsidered factor. If you've been running a company for the last thirty years casting in metal and resin, your masters are all physical. You have no print option. That restricts your ability to switch, because your entire back catalogue requires the older forms of manufacture. To swap would require binning your back catalogue. Businesses that started in the last five years however (take Anvil industries or Artel W) have likely been printing their masters from the word go, and so can make the transition with relative ease.

Does anyone know what the current state of 3d scanners is? How hard would it be to scan an old model to make a digital master?

81759

Post by: BaconCatBug

You say that as if GW's more recent models haven't been using CAD masters, and that the rest of their 20 year old line up SHOULD be binned and replaced/updated.

11029

Post by: Ketara

I'll be honest, I wasn't really thinking of GW. More Heresy Miniatures or the like.

87056

Post by: Valander

Ketara wrote: Ketara wrote:

Does anyone know what the current state of 3d scanners is? How hard would it be to scan an old model to make a digital master?

For larger things digital scanners work ok. Last I checked a few months ago, though, I didn't see any that were at a reasonable price that could get the kind of resolution you want for minis.

This article has some good info on that: https://formlabs.com/blog/how-to-choose-a-3d-scanner-for-3d-printing/

So yeah, that's a huge hurdle for converting old lines into digital, and why we're not going to see a sudden shift. As more companies start embracing initial sculpting done in digital, that will let them choose to go either way more effectively, but for hand sculpted stuff, going to digital is still not "ready for prime time" as it were.

65284

Post by: Stormonu

3D scanning tech isn't tuned very well for the likes of miniatures at the moment. The scans I've run across on places like Thingaverse look really poor/crude compared to made-from-scratch models.

Personally, I'd say in terms of 3D printing we're in the equivalent of the dot matrix printer days of yore - though on the cusp of seeing the equivalent of vectored plotters starting to show up.

We haven't quite had the revolution that's made it a thing where everyone's got one (or more) in a household. It's still a niche hobby.

11029

Post by: Ketara

If 3d scanning isn't quite up to par, that's going to be something of an obstacle to older small companies from making the jump. At the very least, they'll have to maintain both forms of production or bin their back catalogue. And worst case scenario, being run by older people who might not be entirely au fait with modern IT, making the jump might be impossible for them.

I suppose it's one of those classic examples where established firms actually have a harder time of it than younger more agile ones. When the production paradigm shifts, you're left with obsolete plant and difficulty in competing.

77922

Post by: Overread

Ketara wrote: Ketara wrote:If 3d scanning isn't quite up to par, that's going to be something of an obstacle to older small companies from making the jump. At the very least, they'll have to maintain both forms of production or bin their back catalogue. And worst case scenario, being run by older people who might not be entirely au fait with modern IT, making the jump might be impossible for them.

I suppose it's one of those classic examples where established firms actually have a harder time of it than younger more agile ones. When the production paradigm shifts, you're left with obsolete plant and difficulty in competing.

Thing is at present does 3D printing give you that powerful an edge in the market that its going to be a requirement to compete?