Well I use Plasticard alot and I've become rather adept at it, so I'll pipe in with some comments.

In my experience the key is your tools. When I'm using plasticard I find the following tools indispensible:

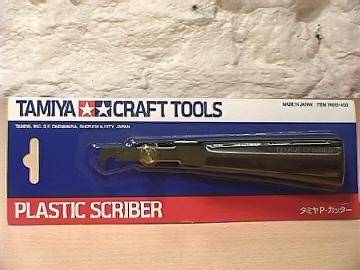

1. A plastic scriber. Here's a link and a picture so you can see what it looks like-

www.hlj.com/product/TAM74015

It pulls out a tiny wedge of plastic at a 45 degree angle from the edge of the blade- basically making a little trench that's shaped like this: |/ except with a 45 degree angle in there

If you're making something with lots of straight lines use this and a metal ruler to trace the pattern.

2. A pencil. Yeah, that's right- a pencil. I always mark my cuts first if it's a piece I've been working on for a while. It seems simple but when you rush sometimes you don't do it and you end up eyeballing something to disapointing results!

3. A pair of uber sharp sewing scissors. I discovered this when I still lived at home (hey- I've been doing this for a while now). If you trace your pattern out on a piece of plasticard you can carefully cut it out with sharp scissors. This works for me on everything but the tickest plasticard- but I only rarely use card that thick. Note that the remaining pieces that you cut away will tend to have a curvature in them as a result of the instrument, so they can kinda ruin a bit of the spare card if you're cutting somethign with lots of curves.

3. Needle files AND sandpaper. Sometimes I like to use needle files but othertimes sandpaper is key. I find that both are very useful.

4. Time. Sometimes you're going to have to cut a piece out 4 times before it looks good. Save the leftover pieces in some ziplock bags. You'd be surprised how often a former mistake turns out to be perfect for a future project.

5. Greenstuff or brownstuff. Sometimes I'll just use greenstuff to add the hard edge to that piece I messed up when I was filing.

6. My engineering drafting tools. I'm in mechanical engineering so it might have seemed like I was never gonna use them when I bought this stuff for my first design classes (most of the real drafting we do is done in

CAD). But these pics show some of the drafting stuff I use for modeling:

A 45 and a 60-30 triangle. These things make drawing squares and certain angles a breeze. I tired to google some simple instructions but couldn't find nice ones. If you're confused as to how to use triangles come see me in Fredericton, New Brunswick, Canada. You can crash in my room and I'll show you the ropes of drafting. I'll even take you to a few of my classes for some mechanical engineering fun

Drafting templates. Go buy one of the large (they're about 8x8"

templates that look like the one in the middle. I was useing that for warhammer dioramas before I was using it for homework

Oh, and when it comes to brand I'm a Staedtler guy- you can't really go wrong with them. They're expensive but always great for their precision and quality. All that drafting stuff is easy to buy at any stationary store (I got all of mine at Staples or Business Depo depending on how long ago it was). The scriber is tougher, but you should be able to find it anywhere that's big on model airplane stuff.

That's all I can think of guys... I hope I've helped.