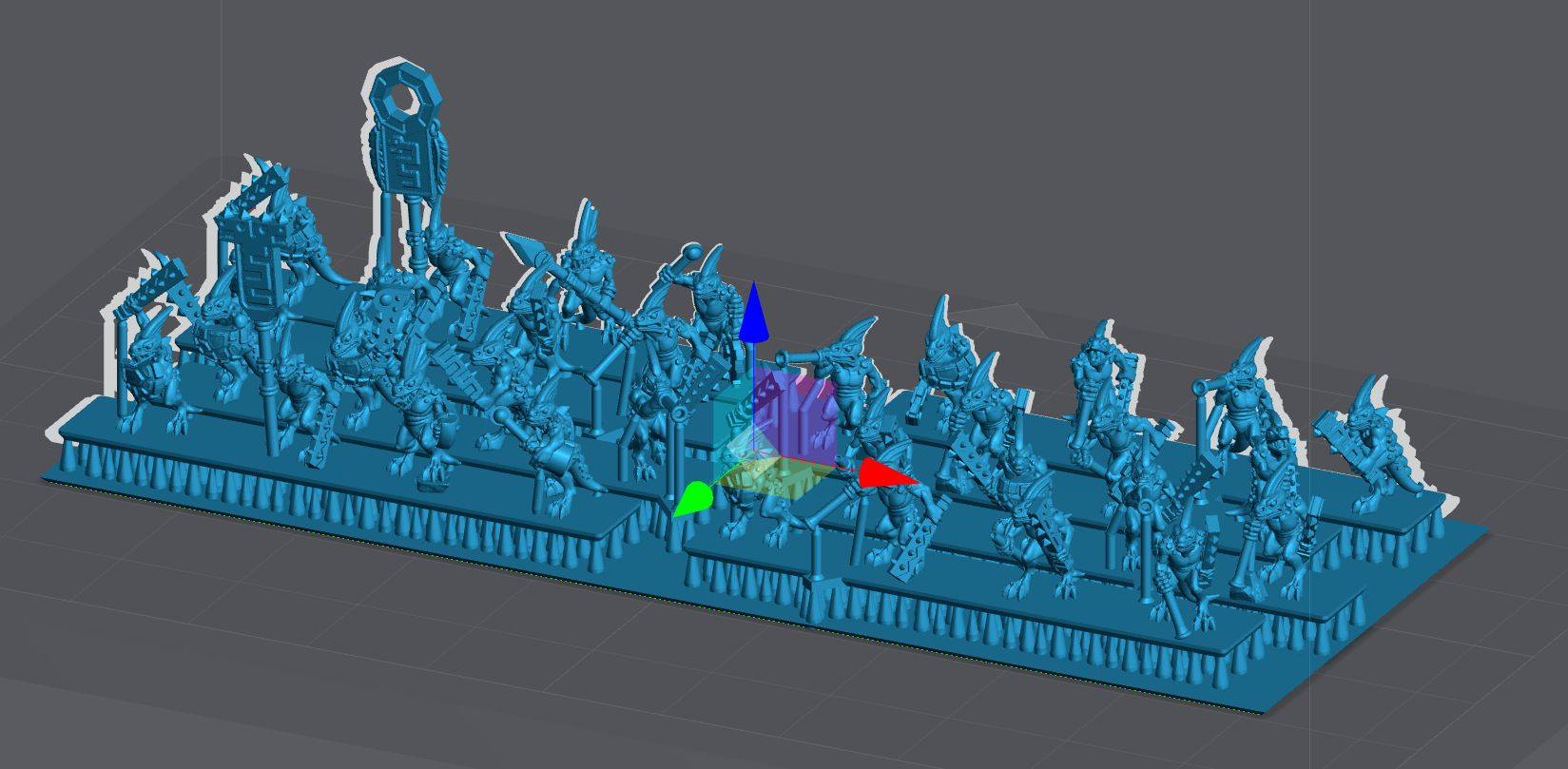

I printed the Saurus and Kroxigor bases with an FDM printer and glued the individual models down to it, but models like the Skinks and Skeletons are very spindly and fragile with small attachment points, so was hoping to print the base integral with them.

Had a go at elevating the models 3mm but not angling them. It worked... mostly. A couple of corners failed (so not a catastropic fail, just some of the corners are a bit thinner than they should be). I had the bases taper originally because they were going to be flat on the build plate and figured the taper would make it easier to lift them off the build plate, but since they're elevated now I should probably get rid of that and it'll let the supports go all the way to the corners.

But they're pretty much bang on the STL design of being 0.8mm (well. 0.75 to 0.85mm).

Also they're still a touch thin, drawn them at 0.8mm, the skeletons came out good because they actually printed at 1 to 1.1mm in spite of being drawn at 0.8mm, now that they're printing accurately they need to be bumped up to 1.1mm permanently I guess.

One annoying thing, resin gets trapped between the supports. I did a 4 bucket wash plus a few minutes in the spinny Anycubic wash station, and there was still resin caught between the bases and the raft.

The Skinks are super annoying though, way too spindly for my liking, the ankles, wrists, blowpipes and tails are so delicate with a handful of failures at those locations across the batch (well, no angles and wrists failed during the print, but I snapped a few off when handling to clean them and remove supports, a couple of blowpipes and tails failed in the print itself).