I was at gencon this year and I had a good chat with the nice people at the wargames factory booth. For those who dont know, Wargames Factory have a small company in the US but their main base of operations is in mainland China. My wife and I had a trip planned to Hong Kong in September and when I mentioned this to them, I was warmly invited to go and have a look around, take some photos and put it up here on Dakka.

As most people have noticed, Wargames Factory are handling quite a few projects at the moment, with Dreamforge being their flagship range for their quality and abilities.

So without further ado, here's how the trip went down, and here is how wargaming plastic sprues are manufactured:

Here is the ferry to China approaching while still in Hong Kong. Apologies for the lack of relevance to wargaming but I love that skyline so much I share it at any excuse I get

Also proof that I braved a mainland Chinese ferry to get you this article!

After a ferry ride and then a silent car ride from a friendly person who spoke no English, I found myself here (apologies for the blur):

The factory is fairly large by wargaming standards. They have a large team of digital sculptors:

And a large team of tooling specialists (only some shown here):

I had to block out anything that was obvious to see as it was quite apparent what they were working on and I did not want to be unwittingly responsible for any spoilers.

The above shows the basic process - a model is sculpted digitally (either in house or externally), or is sculpted organically and then scanned and cleaned up. Next, the model must be cut up into parts that can be made in a 2 part tool. A tool consists of two halves which must pull apart easily, so if you have any undercuts it will simply jam or shred the plastic inside when you try to open it up. The most complicated bit of any wargaming model design is getting those undercuts handled and it is why plastic sculptors have such a slow turnaround relative to resin or PVC sculpts. Once the model is sculpted and split into parts, it then has to be laid out on a sprue. A sprue must be balanced so that when liquid (hot!) plastic flows into it, it flows evenly and pushes out all of the air.

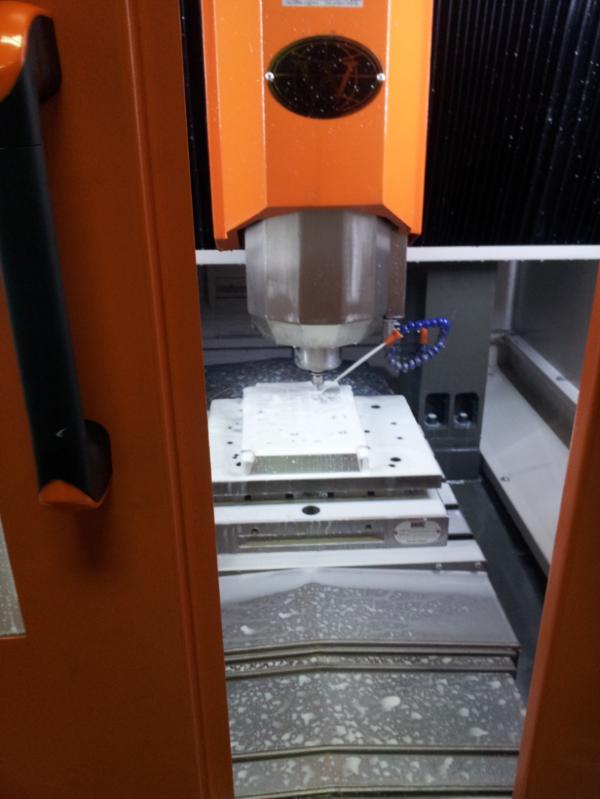

Once the layout has been designed, it is time to cut into large chunks of Steel or Aluminium. A single tool is good for 50,000-500,000 shots, so once you've made it, it will last a very very long time.

Here's some of the equipment used for cutting and some cutting in progress on various types of machines (blurry to protect IP):

You can cut by milling out the metal (as the above pictures show) or by using electrodes which burn into the steel, giving much more detail but requiring more cleanup after tooling and a more complicated setup. Most people use a combination of the two but Wargames Factory try to focus on milling due to the higher overall quality you get as a result of it. The metal has to be perfect quality or you end up with strange things happening like bubbles and burned out areas, so the

raw material costs for the metal are very high.

Here's some post-machine cleanup in progress:

And here are some of the tools that they have made to date. You can see both halves of a tool quite clearly and Dreamforge's stuff is in there somewhere too:

Once a tool has been made, tested, adjusted and tested some more, it is ready for use. All you need for that are some plastic injection moulding machines of which Wargames Factory has a decent number and range. They look like this:

Simply insert the tool, get the technician to operate the machine and out pops perfect sprue after sprue after sprue. Once you have them, time for packaging and shipping which looks like this:

Wargames Factory kindly bought me lunch at a tasty local Chinese place, then we spoke about wargames and the community for a good deal of the day. I missed the last Ferry back to Hong Kong so we ate at a nice Italian restaurant and then I was driven all the way back to the border. Thanks very much to my kind hosts for a real experience - it was amazing being able to see a functional factory in the workshop of the world and is an experience that I'll be able to refer to for my whole life as I was fortunate to be in the right time and place to witness a little bit of China's continual industrialisation first hand.

I thought I'd take a moment to outline plastics in a bit more detail as well, as we often see people on here getting very confused and a single accurate point of reference would probably be quite useful. I've spoken to a lot of people in the industry and any numbers I quote are generalisations, not the prices for any specific manufacturers, including Wargames Factory.

The headline figure that most people talk about is how

GW sell a $40 boxed set which has about 50c worth of plastic in it, so I thought it would be helpful to break that cost down a bit. An average plastic tool for a single wargaming infantry sprue runs $8,000-$17,500 (depending on detail, bits, etc). Sculpting for plastic on top of that is expensive due to the highly qualified people needed, often salaried, but more often outsourced for thousands of dollars per model. Manufacturing requires either heavy equipment and all the costs that go with it, or you have to outsource it to someone who takes their cut. As such, price per sprue can be anything from $0.80 - $3.50. Add on shipping, marketing, warehousing, distribution and retail costs, etc and that $40 gets cut down very quickly, even if the

raw material price is pennies per sprue. Typically 5000+ copies of a sprue have to be sold just to break even. Beyond that things become quite profitable quite quickly, but it is a massive gamble for non-

GW wargaming companies (like mantic and hawk wargames) to take so we should certainly support those who take the risks and be thankful to kickstarter for enabling so many companies to take a chance where before they would have only been able to dream about it.

People also quibble a lot about materials these days as there are so many options out there, so here are the main ones:

Plastic - Polysterene is the stuff that Games Workshop use on their sprues, specifically HIPS. This is the only type of plastic that can be glued by plastic glue (polysterene cement).

Plastic - Restic/PVC - This is the stuff that CMON,

PP, Mantic, Fantasy Flight (X-Wing) and many others are using as a plastic on a lot of their stuff. Technically it is plastic, but it is not the same that we are used to with sprues. The detail tends to be a bit softer as the material shrinks a lot when it sets, warping sharp edges on things like weapons and bending staffs and swords if it dries at an uneven pace. Cleaning up mould lines can be tough. There are chemicals that will clean mould lines but they give off poison fumes so are not readily recommended by companies that use it.

Plastic - ABS - This is what Lego use for their plastic. I've not seen it used on any wargaming models that I can think of, but some model tanks and similar use it.

Resin - There are a huge variety of resins and even more ways to create things with them. They are usually more brittle than other materials, require competent casters to prevent bubbles and issues, and have a very high per-model cost with moulds decaying over as few as 100 models or so, leading to high moulding costs. Most resins shrink a little when setting as well, but by much less than PVC. A single resin model can cost as much as $7-8 to produce.

Metal - There are lots of metals in use as well, typically tin or pewter alloys, with lead being used back in the day and by some small producers still. Metal can be tough to clean but is easier than resin to work with. The

raw material cost can be higher than most resin so it has been phased out by most producers. Metal shrinks a bit when setting as well. Final detail is typically less than resin due to shrinkage but better than PVC.

I hope the above has been interesting and informative and thanks again for the tour of Wargames Factory!