LoER Hobby Challenge #36 (Jan-Feb): Crossings

Cut foam stock of various sizes on my Proxxon.

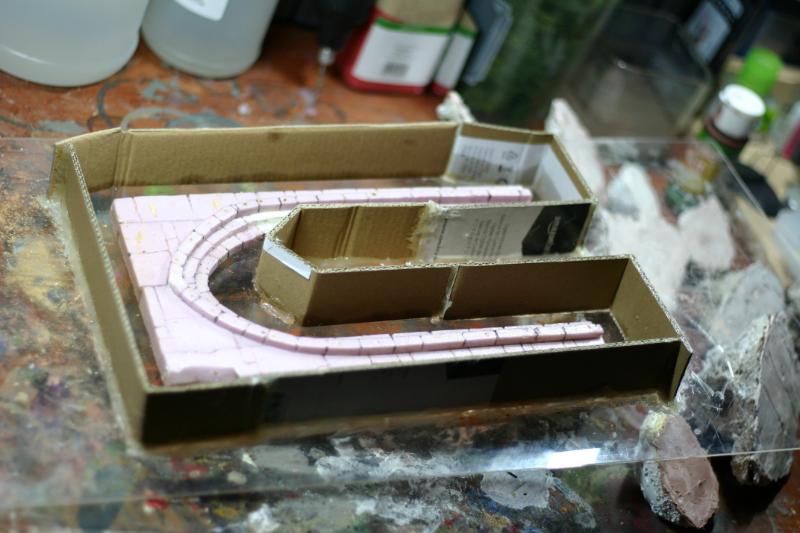

The plan is an attempt at a large Sunken terrain, a ruined gate arch.

Made an arch, but want to try make a mold from this because I need 12 or more of those, but I has no more latex resins to cast molds and no monies for restocks for those resins are quite expensive.

Found videos of folk making simple molds using silicone caulking and water. So that is the plan for caulking i has.

Prep for the mold make.

Lightly glued the arch to the plexiglass

Brushed on Bagbalm as "mold release"

Never molded caulking before, so It is even more sticky than green-stuff, bagbalm does not help but soapy water does, like in tutorial videos.

Gloves proved to be quite useless, sticking to material too quickly.

Doing this on plexiglass turned out to be accidentally genius as it allowed to see through the back side during the application. SO I could see if caulking filled every gap or not.

Soapy water helped with the smell too, but not by much, will finish the rest outside.

Backside see-through was smart.

What was dumb is using cardboard for the sides, not only because it became soggy but because I cant level corners to cardboard uneven flimsy soggy edge.

Removed cardboard

Built frame that has a rigid edge and consistent height

Threw in some dirt as filler in attempt to use less caulking and flattened the corners. So the mold when flipped will stand like a table on 4 corners. Hopefully leveled-ish.

Luckyly I bought 5 tubes thinking that will probably only use 3

Last 2 went into building up the back because it does

sag under its own weight.

Pro tip - Stale Wafer Cookies shims !

First cast!

Kinda meh... I'll see how it looks when painted.

The idea was to cast 2 halfs and glue them together into one arch. The backs might not be strait flat however...

From tutorial videos folks talk about using Joint Compound instead of plaster. Will try Joint Compound tomorrow because plaster is a bit brittle pricey and I am running out.

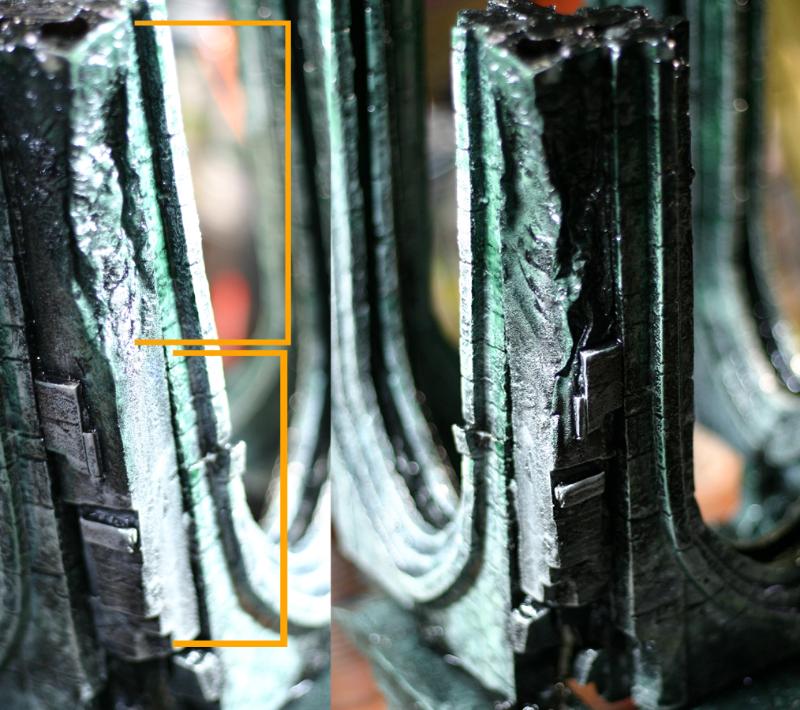

Rough dry-brush just to see how the first cast cameout

Quite impressed! The plan to cheap out on molding material by using caulking worked! About $30 spent

This is a first cast with plaster that was poured into the mold right after the silicone set, meaning that all small artifacts, tiny bit of extra water, and leftover (BagBalm) was still there when I poured. I took out plaster cast before it dried completely and it damaged the cast a bit, and I had to spray it black form a rattle-can , that must of clogged up some small detail. That had to be done because brush bristles would scrape of plaster and leave white scratches all over; At least with a film of paint spray paint I could dry brush the arch.

I expected the cast to look dull with less detail but it is not too bad at all!

Foam matrix is on left, plaster cast on right. ( Keep in mind that the foam matrix on the left was covered in pieces and flakes of silicone and bagbalm, I just painted over everything, so the original detail is not there)

Glued both together with garilla glue

My progress was slow, lots of waiting for things to dry. I tried join compound. It mixed very well, poured beautifully but never dried after 3 days, so I took it apart and noticed that smaller pieces that are dry would crumble easily.

Big fail.

I even tried to mix 1/6 Woodglue with water into the joint compound for sturdiness but that did not help at all.

If I mixed more of the wood glue that would do the trick but then I am not saving any cost on the glue. Might as-well go back to plaster.

Next try I saw perfect cast material and will try that, suppose to be much stronger than plaster, but not as cheap.

I must try concrete too.

Progress.

Finally some perfect cast came in.

This stuff really supercool! Mixes well, pours smoothly, after 30 mins hard enough to pull from that mold without breaking like plaster did.

I even tried to put old spruces in for the support.

For the excess, I made dents in the ground with a rock, now I have some nifty solid rock pieces.

Progress

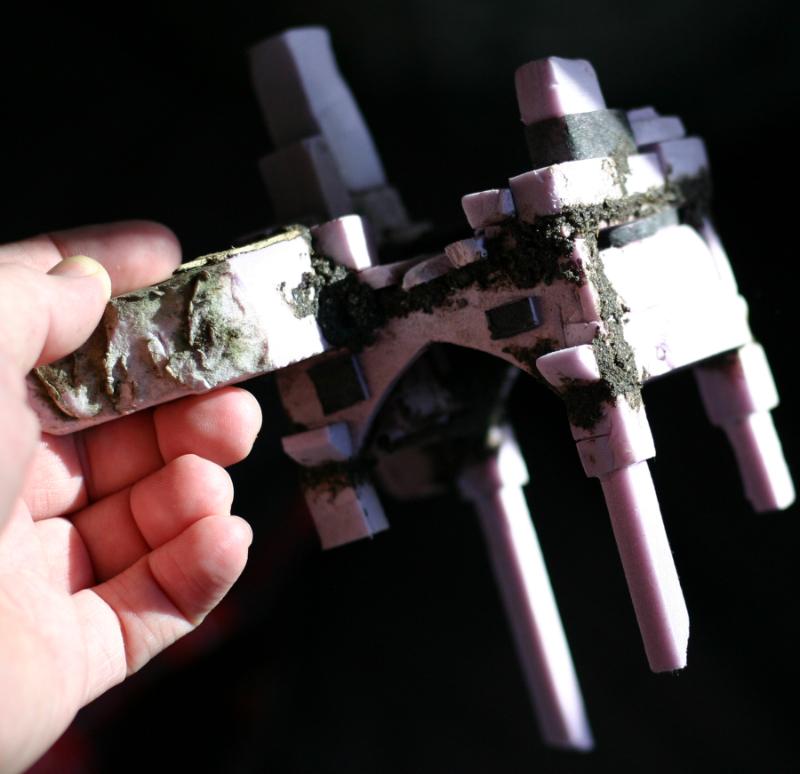

7 pieces cast, glued back to back, spray-painted black.

Adjusting the plan as I go. Instead of ruined wall section of a cathedral with the arches, I'll combine them into a tower of a sort. It is much easier to move it around that way.

Need something for the top

Found some old foam pieces from old projects. Will try to put it all together.

Dry brushed the arches, stained them a bit green (finally good use for that

GW contrast pot), and begin to cover the arches in coats of resin.

This is Aquarium safe resin, usually used in combination with calcium carbonate to make mold aquarium decorations.

So the idea is to coat terrain piece in that, and make it aquarium safe. I have done tests before and it will work.

Casting with that will be pricey, but coating saves a ton of resin and still has the terrain detail.

I have to do one side at a time for resins, and the glues have to cure for full 24 because pieces are big n "heavy" ish.

Progress is slow due to dry time for resins or glues.

There is a bit of a gap, and bowing, the arches are not 90 degree leveled or even and that is due to my redneck-style mold making.

Therefor building up shapes for that extra detail and for the glue to get a good grip on the pieces that don't line up really well.

Progress, Glued, Trimmed, Painted

Now I need to coat the entire tower and newly added corners in that resin and glue the top pieces.

Finally the top pieces coated and dry. Waiting on resin on the arches to dry before gluing together.

Btw, Shininess does not bother me because underwater you cant see it.

I think what you see by the filter is a yellow snail. No puffer, fresh water only

I have 2 fish in the big tank: some type of loach and a plecostomus, can't see them because both like to hide.

Smaller tank has 1-Betta, 1-Otocinclus, 5-Zebra danio, 1-Guppy and bunch of snails. I will get more fish for big tank when the decorations are in; don't know what fish though, perhaps a lot of small schooling fish be nice.

Speaking of, a bit of a problem. Too much foam, not enough plaster, the damn thing floats. Though I was almost done, nope.

So, I have done a test in the past. Used that aquarium safe resin with calcium carbonate to build up a thin shell of 3-4 layers, painted it, and hollowed it out using acetone that melted the foam and left the resin shell. Perfect for wide and larger pieces.

It did work, however there is not way for me to re-seal the inside on something long and narrow. On the arches all I have is 2 layers of paint and 2 thin layers of resin.

Ether need to build up 4-5 layers with calcium carbonate, repaint, re-seal, hollow-out with acetone, wash out, air-out, somehow re-seal the inside while losing all detail on the surface. Or just add something heavy to the arches so it sinks. Or, spray it with matt varnish and use it outside the tank for something else.

While I am at it.

Indirectly relating to the arches but will be part of finished look.

Got these driftwood trees.

However over a month underwater I noticed some black and green molding happening. Pulled them out, dried them up, and want to coat them in resin too for long term use. But this time got PlastiDip clear Matt spray to seal the trees with. Folk use Matt black PlastiDip to paint aquarium filter piping to make it less visible and be aquarium safe. However this stuff is not very durable and the rubbery film can be peeled off (from my research), figured for the trees should be sturdy enough. Hope this works.

Automatically Appended Next Post:

Automatically Appended Next Post:

MacPhail wrote:

MacPhail wrote:Oof, that's a bummer so close to the end. What about mounting it on a flat base that you could bury in the gravel? The acetone trick seems like a huge new step.

Base would make sense, also it will secure the legs together, because now they are by them selves and if accidentally bumped might crack off.

Well, my tank is already set up and planted, kinda don't want to disturb it.

Plus wanted the legs free standing (even if they are vulnerable) that way I can pull it out, clean tank, put piece back in.

Plus, I don't think that gravel is heavy enough to keep it down lolz. I feels like that thing need some serious weights to keep it down.

Think I figured out what to try.

Will attempt to pour acetone from the bottoms, down each "foam column" ie the corner, because the corners are the largest foam pieces.

Hopefully the 2 layers of paint and 1 layer of resin will hold-on long enough for me to pour plaster into the hole burned out by the acetone! Sealing the interior from melted foam and adding weight.

If this works then hurray! If not, then I will be posting progress of reattaching arches with new corners made from rocks and wood-glue.

________________________________________________________________________________________

IT WORKED!!!!

kidding, of course it didn't lolz

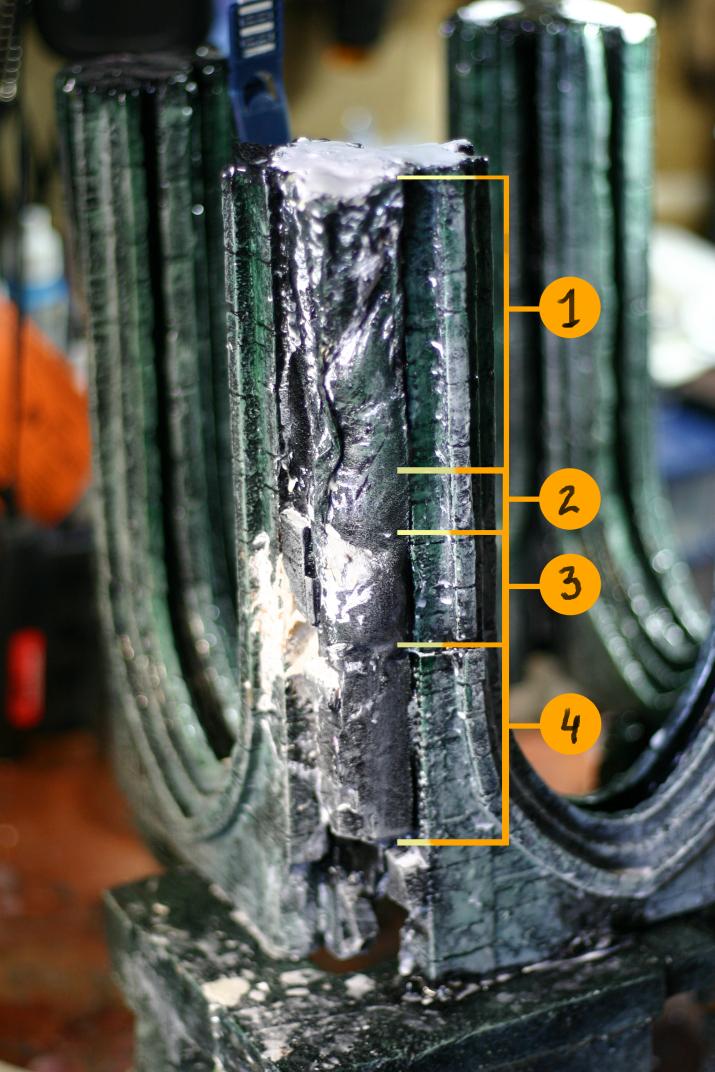

(decided to document process for such an unusual thing)

First try:

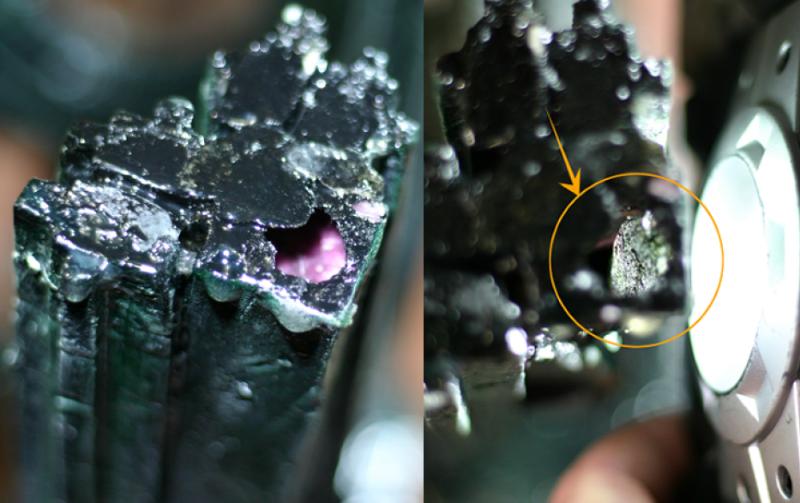

Made a hole to melt down the column.

Melting went well, and left extra thin wall. Here you can see the light shining right through it.

As more of foam melted, the column began to fold on it self and wrinkle. sadface

But it held together and I though to try and pour some PerfectCast but acetone must of melted through some cracks unseen to me. Emergency plastiline patching did not help at first. Lots of patch, pour, clean, patch pour clean, repeat.

Eventually:

4) - Left this part foam

3) - Was the first "pour" that did not leak out but blew out the column.

2) - Second pour was a test and helped to seal up some other leaks.

1) - Rest filled up well with PerfectCast but I was unable to un-wrinkle the column

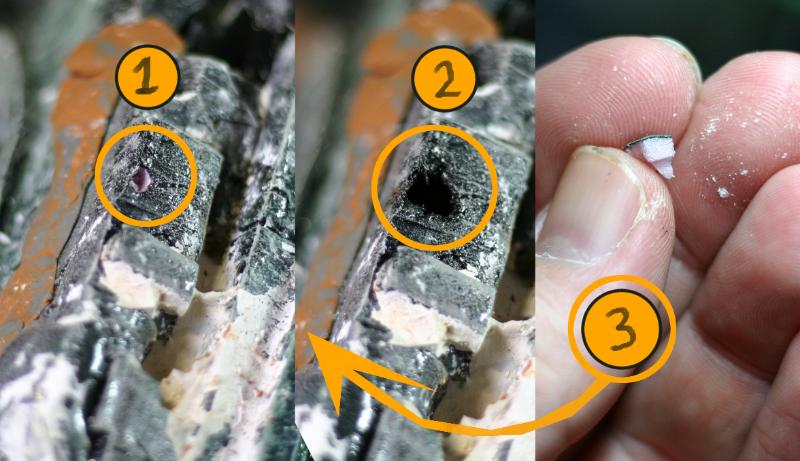

Second Try:

Decided to melt column in smaller sections and from the side instead of one big melt down from the bottom.

1) - Poke a hole

2) - Pour acetone, fill with plaster, move on.

3) - To give an idea of the thickness that I am working with. Plastelin helped in holding shape and prevent leaks.

Was able to fill 4 holes, even if its plaster foam plaster foam.

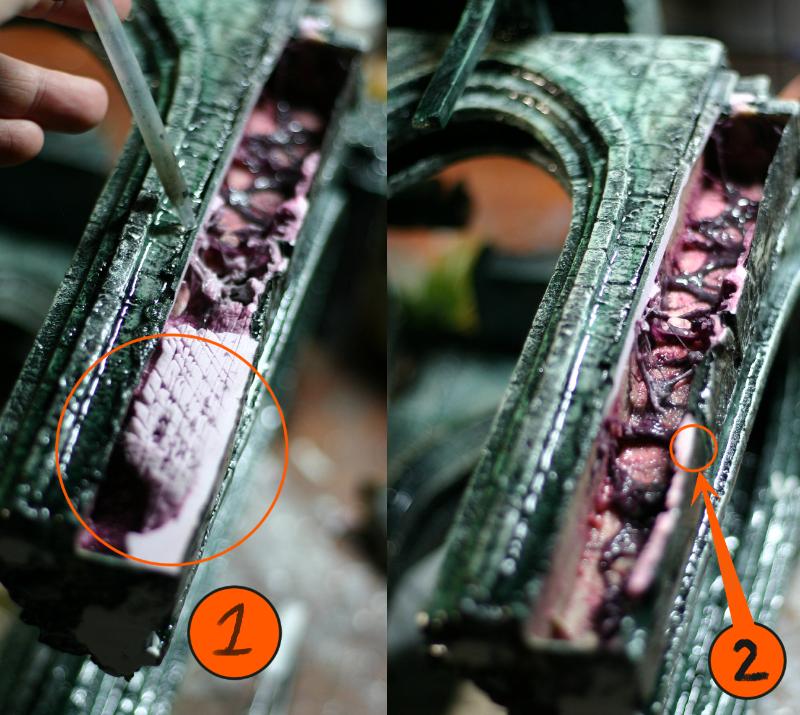

Third try:

Decided to take entire top off the corner section and fill from top.

1) - Scoring before acetone accelerates melting dramatically

2) - Uneven melt left wall in places thin/thick, helps with holding the shape.

Extra plaster is poured over flat surface and later repurposed as filler for the next pour.

First pour pushed out the walls a bit. Second pour filled in the rest but was much lower due to wall bulging. Ended up building up wood-glue/dirt mixture to make up the difference.

Progress

Did a quick dunk test, it no longer floats!

You can see warped corners and wrinkled holes around.

Now need to finish painting, sealing, waiting to dry.

I can always make more smaller pieces and glue to this rig at a later time to built it up some more. And eventually have part of it sticking out of water.

Progress

So it sinks but the side of the arch that was made from foam is still raised. However this time a small rock on top will do the trick.

All coated in resin and dry.

Will take pictures in aquarium after the trees are in.

Had to glue them to rocks to give weight, because sticking them in and taking them out without disturbing the substrait would be much preferred.

Coated them with resin too to seal the glue and paint.

All done! this project is not finished yet, more ruin pieces must be added in the future. And a background be nice.