| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 12:56:46

Subject: Casting pieces with Resin -- questions for experts

|

|

[MOD]

Anti-piracy Officer

Somewhere in south-central England.

|

Hi all,

I have decided to make a variant Marines army using M113 personnel carrier models for the vehicles.

I would like to cast up pieces to look like the vertical exhaust pipes found on the Rhino. I figure I can easily build a master model using plastic card and rod. However I don't know anything about casting in resin.

Are there any articles in Dakka about resin casting?

Does anyone know about any tutorials or guides on line?

Would any experienced caster like to share their wisdom in this thread? A quick rough guide would be enough to get me started.

Questions

What is the best type of resin for this purpose?

What materials do I need to buy? (Brand names and descriptions.)

Mould making material

Casting resin materials

Any useful tools

Any good starter kits

Does the mould making process use heat? Can a polystyrene master piece be used?

Can I use one master item so make several moulds or is it destroyed in the mould making process?

Does the resin curing process develop a lot of heat? How long does it take?

Are the chemicals involved stinky or poisonous?

Any useful advice

Shall I cast the pieces one at a time, lying flat with inside face upmost, or make a vertical mould with an inlet tube so it fills from the bottom?

Is it easy to make a multiple model mould so I can cast perhaps four items at one time? Could this be done by making a single mould and using castings from it to make a battery of second generation moulds?

Thank you in advance for your help and advice…

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 13:19:01

Subject: Casting pieces with Resin -- questions for experts

|

|

Lord Commander in a Plush Chair

|

Isn't the good stuff for moulds RTV rubber? This is what a lot of serious modellers I know use. Don't know if it's hot, but they cast things made from plastic card in them.

I wouldn't make 2nd and third generation moulds, make several moulds from one master. Apart from the loss in detail, the cast that comes out of a mould is slightly smaller than the master, which definately has to be factored in when making scale models and may be a noticable problem when making moulds several generations old.

I know people make the outer walls of the mould using lego bricks to make the floor and walls. Then pour the liquid rubber in, push your part in (cover in release agent first) and push a few rods in at the corners of the mould to provide locating pegs for aligning the mould correctly later. Once that's set you put release agent powder on the surface of the rubber and and part being cast, and pour the rest of the rubber on.

Once that's set you pull the halves of the mould apart, pull the part out and the mould is nearly done. You then have to cut troughs for the resin to be poured in, some at the top, and some at the bottom to allow the air to escape. And the resin compounds and vapours are nasty.

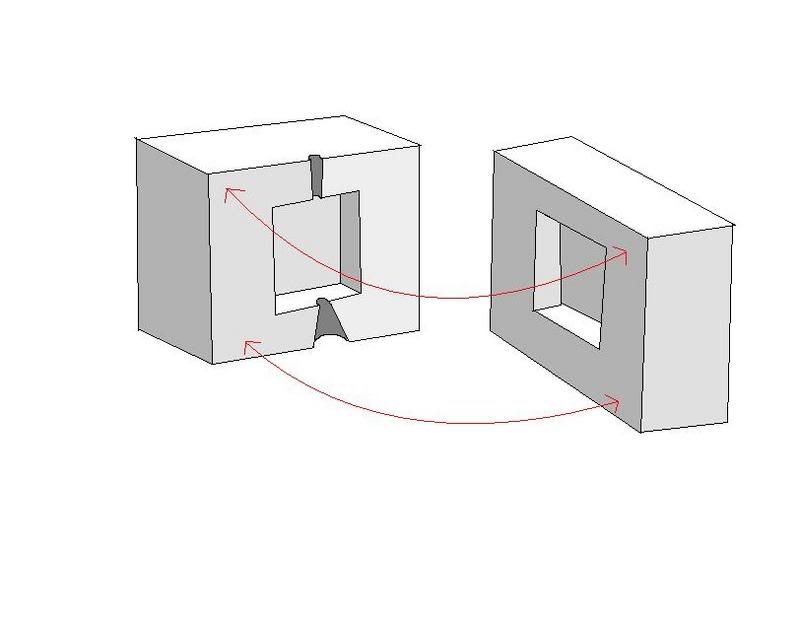

I made this drawing fr someone else, it lacks the locating pins, but one in each corner would be good. Then you avoid 'mould slippage'.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 13:24:58

Subject: Re:Casting pieces with Resin -- questions for experts

|

|

Regular Dakkanaut

|

These are one to one ratio mixtures that when combined cure really fast. Like 15 minutes total. Browse about their website for examples and demos... They rock. You can buy the small Trial Size in each product. That is what I have been using now for awhile. I went through using all sorts of resins and could not get the stuff to work right...

This stuff works PERFECTLY.

For making the mold:

http://www.smooth-on.com/Silicone-Rubber-an/c2_1113_1136/index.html

This stuff for making the copy:

http://www.smooth-on.com/Urethane-Plastic-a/c5_1120_1209/index.html

|

Adepticon Pics...

http://s169.photobucket.com/albums/u215/theblklotus/ |

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 14:10:49

Subject: Casting pieces with Resin -- questions for experts

|

|

40kenthus

|

RTV does not use heat to cure & can take just about anything as a master. In most cases the master will survive the mold process.

The easiest mold to make is a "dump mold". Its a one sided mold, just pour the resin into the open pit. Sounds like it would work well for surface detail bits.

I have a lot about casting and molding on my blog. You can start here:

http://chicagoterrainfactory.wordpress.com/resin-casting/

http://chicagoterrainfactory.wordpress.com/2007/03/21/bases-making-an-rtv-mold/

UltraWerke has a number of well detailed molding tutorials.

http://ultrawerke.blogspot.com/

I'm not familiar with UK suppliers of resin and RTV, but go over to the Hirst Arts forums & look around there. There should be plenty of links in Product Reviews and Questions & Tips.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 14:29:05

Subject: Casting pieces with Resin -- questions for experts

|

|

Willing Inquisitorial Excruciator

|

Micromark (in the US) www.mircromark.com has a casting kit. This might be a good place to check out just to see what they recommend.

Also, I just finished watching a couple of tutorials on youtube on casting. Search for "mould" "casting" and "green stuff". They should all come up. I found them very helpful.

|

Legio Suturvora 2000 points (painted) Legio Suturvora 2000 points (painted)

30k Word Bearers 2000 points (in progress) 30k Word Bearers 2000 points (in progress)

Daemonhunters 1000 points (painted) Daemonhunters 1000 points (painted)

Flesh Tearers 2000+ points (painted) - Balt GT '02 52nd; Balt GT '05 16th Flesh Tearers 2000+ points (painted) - Balt GT '02 52nd; Balt GT '05 16th

Kabal of the Tortured Soul 2000+ points (painted) - Balt GT '08 85th; Mechanicon '09 12th Kabal of the Tortured Soul 2000+ points (painted) - Balt GT '08 85th; Mechanicon '09 12th

Greenwing 1000 points (painted) - Adepticon Team Tourny 2013 Greenwing 1000 points (painted) - Adepticon Team Tourny 2013

"There is rational thought here. It's just swimming through a sea of stupid and is often concealed from view by the waves of irrational conclusions." - Railguns |

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 14:31:39

Subject: Casting pieces with Resin -- questions for experts

|

|

Executing Exarch

|

RTV = room temperature vulcanizing

hense no heat

This site is a little dated but good:

http://www.hirstarts.com/moldmake/moldmaking.html#silicone

Be warned RTV rubber / silicone is really expensive

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 15:01:44

Subject: Re:Casting pieces with Resin -- questions for experts

|

|

Grovelin' Grot

Sweden

|

You're in the UK? If so, methinks http://tiranti.co.uk/ is your best bet for casting and moldmaking materials. As for online tutorials, I'm afraid I'm of no help. Most of my old scratchbuilding bookmarks seem dead

Some quick answers off the top of my head, I could be wrong here:

The 2 applicable types of resin would be Polyester and Polyurethane. Polyester is cheaper, harder to work with once cured and a bit more brittle. http://www.ramshacklegames.co.uk/ uses it for complete vehicle sets though, so it'll probably work fine for your purposes. Polyurethane is the stuff Forgeworld uses ( AFAIK).

RTV (Room Temperature Vulcanizing) 2-part silicone rubber is best suited for making molds. If one side of your exhausts can be entirely flat, you could get away with 1-piece molds. If you're using RTV Silicone, your original will survive the process, but I'd suggest making several originals and 1 big mold for all of them if you're gonna need lots of copies. An alternative is, like you suggested, to do a 2nd generation mold from your first castings. The chemicals involved most certainly ARE bad for you. Proper precautions and a trusted assistant recommended.

For the products I've used, curing time on the silicone was 24hrs and curing time on the resin was 10 minutes.

I'll have another look for a proper tutorial later, if I find one I'll post here. Good luck anyways.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 15:09:17

Subject: Casting pieces with Resin -- questions for experts

|

|

[MOD]

Anti-piracy Officer

Somewhere in south-central England.

|

There's some great information guys.

Thank you.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 20:32:03

Subject: Re:Casting pieces with Resin -- questions for experts

|

|

Cowboy Wannabe

Sacramento

|

I highly recommend the Smooth-On line of products. I got a starter set from them, and armed with a little bit of advice from Hirst, was able to crank out a few molds and many casts from the molds. The kit came with release spray, instructions, a sample, resin A and B, and RTV rubber A and B. I think it cost something like $25, which considering each set of resin or rubber costs up to $20, was a great deal, and perfect for this volume of casting.

I would however recomend a slower setting resin than is often supplied. For thin parts, the resin will set up VERY quickly, on the order of a minute. Since you have to stir part A and B for 30 seconds.... not alot of working time. I would waste roughly 50% of the resin every time, and that was with several (small) molds ready to go.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/02 21:28:57

Subject: Re:Casting pieces with Resin -- questions for experts

|

|

40kenthus

|

lasgunpacker wrote:

I would however recomend a slower setting resin than is often supplied. For thin parts, the resin will set up VERY quickly, on the order of a minute. Since you have to stir part A and B for 30 seconds.... not alot of working time. I would waste roughly 50% of the resin every time, and that was with several (small) molds ready to go.

I wonder if an ice bath would work to slow down the curing process (put the cup in the ice, not the ice in the cup!)

My winter resin set time is about double what my summer set time is. I work in my basement, so the air temp is about 20F degrees colder in the winter months.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/03 17:55:10

Subject: Casting pieces with Resin -- questions for experts

|

|

Tzeentch Aspiring Sorcerer Riding a Disc

|

I have the resin kit sold at Micromark. It works very well, and I'd recommend it, but I have not tried these other versions.

There are likely several right ways to do this.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2008/12/03 19:37:57

Subject: Casting pieces with Resin -- questions for experts

|

|

[MOD]

Anti-piracy Officer

Somewhere in south-central England.

|

I should buy a starter kit to have a go, then expand on it to do the real job.

|

|

|

|

|

|

|

|