| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2009/08/30 03:36:05

Subject: Fixing bent plastic?

|

|

Long-Range Ultramarine Land Speeder Pilot

|

Hey folks,

I started dry-fitting some landraider parts together tonight and found that one part is badly warped on one side.

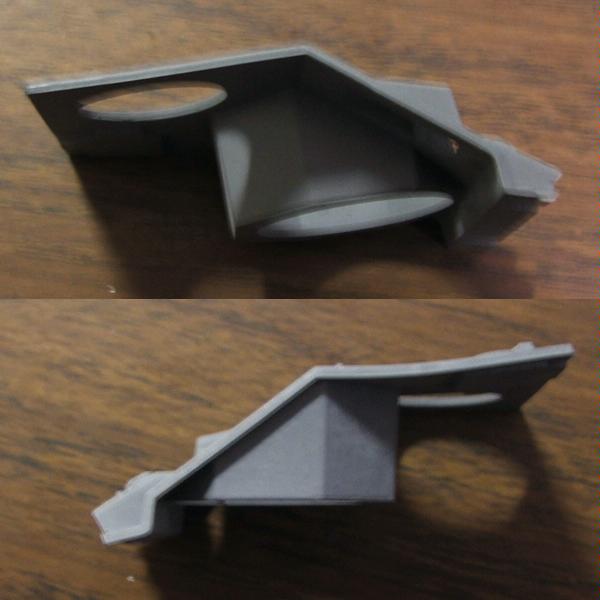

These are two shots of the same part. As you can see the lower one is distinctly bent out of shape. This isn't a resin part, (I kinda expect large resin parts to warp) this is directly from the standard GW Landraider kit.

Any ideas how to fix this ? will heating it in warm water work like it does for resin ? I could glue it and hold it down but it would take quite a bit of pressure and I'd be afraid the glue couldn't hold.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2009/08/30 03:55:54

Subject: Fixing bent plastic?

|

|

Renegade Inquisitor with a Bound Daemon

Tied and gagged in the back of your car

|

Heat it up and then start bending it. Injection plastic is more malluable then resin, so it should actually be easier.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2009/08/30 09:03:13

Subject: Fixing bent plastic?

|

|

[MOD]

Anti-piracy Officer

Somewhere in south-central England.

|

Land Raider and that kind of injection plastic kit are made of polystyrene which gets soft at about 95 degrees centigrade. (The exact physical properties are on Wikipedia.)

You can easily get this temperature with either a pan of boiling water or the steam from the spout of a kettle.

Be very careful how you hold the part as you can get very badly burned by boiling water or steam. Long tweezers are best, and gloves or a tea-towel to protect your hands.

Dip the part in the water or hold it in the steam for a few seconds then try to bend it gently. By trial and error you will get the feel of how long the part needs to be heated. The timing depends partly on how thick the part it.

Practice on waste sprue before you work on your actual part.

Once it's bent to the right shape it will cool and harden quickly under the cold tap.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2009/08/30 09:27:03

Subject: Fixing bent plastic?

|

|

Renegade Inquisitor with a Bound Daemon

Tied and gagged in the back of your car

|

Oh, and use a hammer to temper it... right?

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2009/08/30 09:50:48

Subject: Re:Fixing bent plastic?

|

|

Wrathful Warlord Titan Commander

|

This part of the land raider gets fit into a "gap". It will stay in place, no matter if you fix it first or just glue it as is.

I think killkrazy tips are fine, may be not easy to apply the correct temperature.

You may use either water or air to heathen plastics.

|

Target locked,ready to fire

In dedicatio imperatum ultra articulo mortis.

H.B.M.C :

We were wrong. It's not the 40k End Times. It's the Trademarkening.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2009/08/31 01:57:27

Subject: Fixing bent plastic?

|

|

Anti-Armour Swiss Guard

|

Fafnir wrote:Oh, and use a hammer to temper it... right?

No. You do not need to use a hammer. At all.

As noted, it softens at around 95*C. Steam or boiling water. Allow to soften, bend back into shape and either allow to cool by itself, or dunk it in cold water to set it quicker.

|

I'm OVER 50 (and so far over everyone's BS, too).

Old enough to know better, young enough to not give a ****.

That is not dead which can eternal lie ...

... and yet, with strange aeons, even death may die.

|

|

|

|

|

|

|