| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2012/04/17 20:40:19

Subject: Making Plastic Models

|

|

Veteran Inquisitorial Tyranid Xenokiller

|

I'm sure this question has been asked a few times before, but does anyone know the process of making plastic miniatures? Like, if GW wanted to sculpt a new infantry model, what is the process of doing it from start to finish?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/17 20:46:45

Subject: Making Plastic Models

|

|

Longtime Dakkanaut

|

Generally (and simplified slightly) as follows:

Sculpt at 3 up. (2 up for larger models)

Numerous resin casts are made to test the sculpt and ensure all details are correct. These are also used for production to protect the work done on the master.

A resin 3 up is cut up for sprue making.

A toolmaker scans the model parts using a pantograph to cut a steel mould. The pantograph reduces the movement of the cutting head relative to the probe so the mould is cut at the correct size.

Sprue channels / injection points cut into the mould.

Mould is mounted to injection moulding machine for production.

With the advent of digital sculpting, a digital sculpt can be arranged to cut the mould using CNC. Smaller run moulds may be made using aluminium rather than steel, which allows for faster machining, but has a lower lifespan.

A tradtional sculpt can (as mentioned below) also be scanned to provide digital geometry for CNC.

The process of machining the mould is costly - it's a skilled job and has to be done right. Metal moulds obviously have no give, so the parts need to be arranged so that eliminating undercuts doesn't compromised detail too much. Again a digital production method allows easier cutting up of the model to eliminate undercuts and can (assuming the software is clever) identify loss of detail in the provided geometry.

There are cheaper methods of making moulds, using an epoxy with metal filler, but these are less suitable for large scale productions.

|

|

This message was edited 3 times. Last update was at 2012/04/17 20:52:04

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/17 20:50:10

Subject: Making Plastic Models

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

1. Design, using 3 ups in GS which are then scanned into a computer and edited with an AutoCad type program. This is also where the sprue itself is designed along with how the model will separate into it's individual parts.

2. Routing the mold. This is done with a computerized CNC machine which mills how the cavities in metal where the plastic will flow to create the model. This is arguably the most expensive part of making plastic models as the molds are not exactly cheap to make(nor is the CNC machine).

3. Injection molding. Here the plastic starts in pellet form. It is fed into an auger which pressurizes the plastic along with heat to form a liquid that rapidly cools. The auger forces the plastic into the mold which then cools off in mere seconds and then the new sprue is pushed out of the mold into a collection bin.

4. The various sprues for a kit are bundled together in their respective boxes and are packed together on palettes for distribution.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/17 21:12:26

Subject: Making Plastic Models

|

|

Shadowy Grot Kommittee Memba

The Great State of New Jersey

|

Aerethan wrote:1. Design, using 3 ups in GS which are then scanned into a computer and edited with an AutoCad type program. This is also where the sprue itself is designed along with how the model will separate into it's individual parts.

2. Routing the mold. This is done with a computerized CNC machine which mills how the cavities in metal where the plastic will flow to create the model. This is arguably the most expensive part of making plastic models as the molds are not exactly cheap to make(nor is the CNC machine).

GW's CAD pipeline is reversed. They design on the computer and then finish sculpting by hand with a print. To my knowledge they aren't using CNC to produce the molds, they are still using the traditional 3-up (actually they use 2-ups now) pantograph method.

|

|

This message was edited 1 time. Last update was at 2012/04/17 21:12:47

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/17 21:48:16

Subject: Re:Making Plastic Models

|

|

Veteran Inquisitorial Tyranid Xenokiller

|

Thanks a lot for the info. I learned something today, and I have access to CAD... so heh, I might actually be able to design a model or two...

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 01:32:15

Subject: Making Plastic Models

|

|

Anti-Armour Swiss Guard

|

The plastics injection gear can be sourced for between $5k and $10k and does not usually include the compressor or power hookups OR coolant systems.

It CAN be done in a garage setup, but isn't cheap and the die making (you need TWO dies for each sprue, minimum (front and back) )

|

I'm OVER 50 (and so far over everyone's BS, too).

Old enough to know better, young enough to not give a ****.

That is not dead which can eternal lie ...

... and yet, with strange aeons, even death may die.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 02:00:11

Subject: Re:Making Plastic Models

|

|

Hellish Haemonculus

|

I'm interested in the answer to this question. Unfortunately, I do not understand a lot of the technical language in the answers given so far. Could we maybe give a simpler version for those of us who are just simple lumberjacks? I'm not trying to be a jerk, I just don't know what a 3 up is, or a CNC, or a pantograph, nor which part of what has the probe that was mentioned.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 03:48:02

Subject: Making Plastic Models

|

|

Dakka Veteran

|

Someone posted his garage set up for injection molding with a good video explaining the process.

Found it:

http://www.dakkadakka.com/dakkaforum/posts/list/432505.page

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 04:35:21

Subject: Making Plastic Models

|

|

Lord of the Fleet

|

There a few garage plastic makers out there, but not too many (proxy models was one I think)

And whatever you do, dont drop the mold! Or get you hand stuck in it...

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 05:12:23

Subject: Re:Making Plastic Models

|

|

Anti-Armour Swiss Guard

|

Jimsolo wrote:I'm interested in the answer to this question. Unfortunately, I do not understand a lot of the technical language in the answers given so far. Could we maybe give a simpler version for those of us who are just simple lumberjacks? I'm not trying to be a jerk, I just don't know what a 3 up is, or a CNC, or a pantograph, nor which part of what has the probe that was mentioned.

A 3-up is a master model that is 3x the height/width/depth, so a 25mm figure would have a 75mm tall "3-up" (it would also be on a 3" base).

GW used to talk about 3-ups all the time (so did Jervis in his monthly waffle column). It was too problematic to sculpt a miniature at 28mm, so it is made larger and then a reduction is made from the master to make the mould dies.

CNC is "Computer number control". It is generally used for computer controlled tools - like routers, milling machines, etc. You put the design into the computer end and press start. The machine does the rest. A lot of the MDF and HDF terrain available these days uses CNC equipment (like laser cutters).

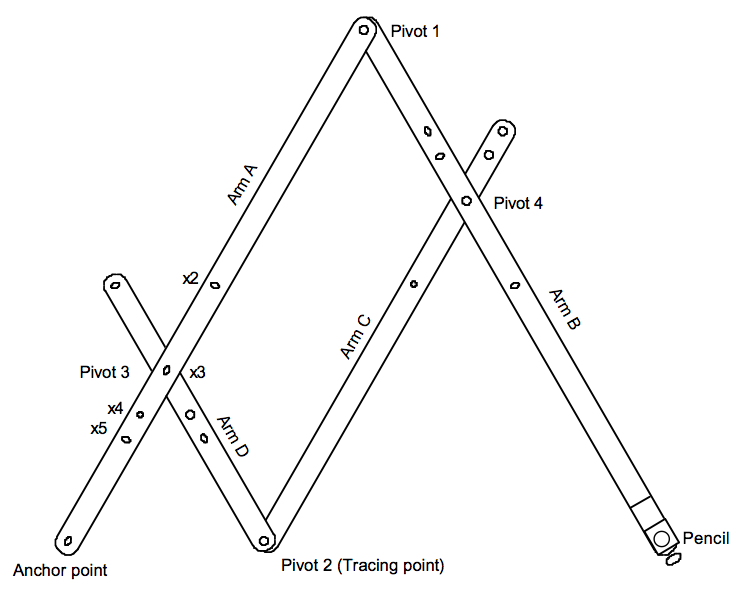

A pantograph is a scale enlarger/reducer. I had one as a kid that allowed me to enlarge or reduce while copying a drawing. I moved a probe around and over the lines and depending on which end I used, it either enlarged it or reduced it. It looked like one of these.

The modelling version replaces the drawing point with a cutting tool. The probe is part of the pantograph.

The modeller moves the probe over the surface of the model and the pantograph tool cuts it out at the set desired scale.

|

I'm OVER 50 (and so far over everyone's BS, too).

Old enough to know better, young enough to not give a ****.

That is not dead which can eternal lie ...

... and yet, with strange aeons, even death may die.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 13:57:10

Subject: Making Plastic Models

|

|

Brigadier General

|

Thanks for linking that. I was wondering the other day how Proxie models does it, and now I know. I assumed his setup could only do more simple blocky designs for bases/buildings/tanks, but the video shows that he's got his own CNC machines and is working on being able to make his own characters!

Every hobbyist should see this video.

|

|

This message was edited 2 times. Last update was at 2012/04/18 14:02:30

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 19:12:54

Subject: Making Plastic Models

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

If he wanted to(not that he would) he could scan in just about any GW part and design a sprue for them on his computer and then make a mold of it. With that small of a machine he couldn't do the same size sprues that GW does, but if he wanted 100 of the same single model he could pull it off with relative ease.

If I win the lottery I'll be doing this with 6th edition Empire soldiers!

Also, the bases he sells are dirt cheap. $4 for like 40 20mm bases!!!

Luckily HIPS is rather inexpensive(like $.70 per pound or something) so that is how he can offer bases for so cheap.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 19:55:12

Subject: Making Plastic Models

|

|

Shadowy Grot Kommittee Memba

The Great State of New Jersey

|

Aerethan wrote:If he wanted to(not that he would) he could scan in just about any GW part and design a sprue for them on his computer and then make a mold of it. With that small of a machine he couldn't do the same size sprues that GW does, but if he wanted 100 of the same single model he could pull it off with relative ease.

Its really not that cost efficient for just 100 models... also, having actually USED 3D scanners in the past, you're looking at some VERY VERY expensive pieces of hardware to do what you want to do. The lower end of the spectrum doesn't have the resolution needed to capture the fine detail of GW minis accurately.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 19:57:58

Subject: Making Plastic Models

|

|

Dark Angels Librarian with Book of Secrets

|

DemetriDominov wrote:I'm sure this question has been asked a few times before, but does anyone know the process of making plastic miniatures? Like, if GW wanted to sculpt a new infantry model, what is the process of doing it from start to finish?

Have a couple million bucks.

buy huge machines and lots of plastic.

Hire people smarter than you to design and work the machines.

That's how to make minis...

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/18 20:20:35

Subject: Making Plastic Models

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

chaos0xomega wrote:Aerethan wrote:If he wanted to(not that he would) he could scan in just about any GW part and design a sprue for them on his computer and then make a mold of it. With that small of a machine he couldn't do the same size sprues that GW does, but if he wanted 100 of the same single model he could pull it off with relative ease.

Its really not that cost efficient for just 100 models... also, having actually USED 3D scanners in the past, you're looking at some VERY VERY expensive pieces of hardware to do what you want to do. The lower end of the spectrum doesn't have the resolution needed to capture the fine detail of GW minis accurately.

Well keep in mind that I mostly mean OOP models that are nigh impossible to find(like my 6th edition Empire soldiers).

Also, keep in mind that this guy has already spent expensive parts of the process. He owns an injection molder, and 2 CNC machines as well as software. Metal blanks aren't really expensive and the only cost to him personally at this point is the time it takes to cut the molds. If I had access to this setup I'd create all manner of frivolous molds for things I want that are no longer available or are insanely hard to find.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/19 19:04:58

Subject: Making Plastic Models

|

|

Shadowy Grot Kommittee Memba

The Great State of New Jersey

|

Most of the unavailable/hard to find things are metal models at this point, you do realize that metal minis can't be made via plastic injection (at least not conventioal methods, you wouldn't be able to use a metal mold for them at any rate), right?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2012/04/20 14:13:03

Subject: Making Plastic Models

|

|

Brigadier General

|

chaos0xomega wrote:Most of the unavailable/hard to find things are metal models at this point, you do realize that metal minis can't be made via plastic injection (at least not conventioal methods, you wouldn't be able to use a metal mold for them at any rate), right?

A fair point. The flexibility of the rubber molds used for metal mean that many undercuts can be done that aren't possible in most non-sliding (multipart, mold type) molds used for plastic models.

Also, those looking into self casting should note that when looking into a home setup, most things are much easier to cast in metal or resin. Rubber (or scilicon for resin) molds are far easier to make at home, and you can do it yourself with much less effort that a plastic injection molding system.

Lots of info about metal casting here:

http://www.princeaugust.ie/

Lots of other threads on dakka and elsewhere about casting.

The proxie models system works well for simple mass-produced items like bases. It can do more detailed things, but there's an even greater and more expensive learning curve.

|

|

|

|

|

|

|

|