Thanks guys. The aft section was a real pain as I had nothing of the correct height to rest it on so out came the bread XD

Anyway, another day and some more glueing and sanding. I've also been reading and looking for extra bits. Its starting to take shape now but it feels like its missing something. Looking online shows up a whole load of extra etched brass details that I feel it really does need. I also want to get a proper laser cut, wooden deck cos the plastic one looks a bit lacking. I guess this is just a disadvantage of injection moulding. You can also get hold of brass weapons. I want some of these because...Well the plastic guns are fiddly and I cant get the barrels right, so they will be a stop gap until I get some brass ones.

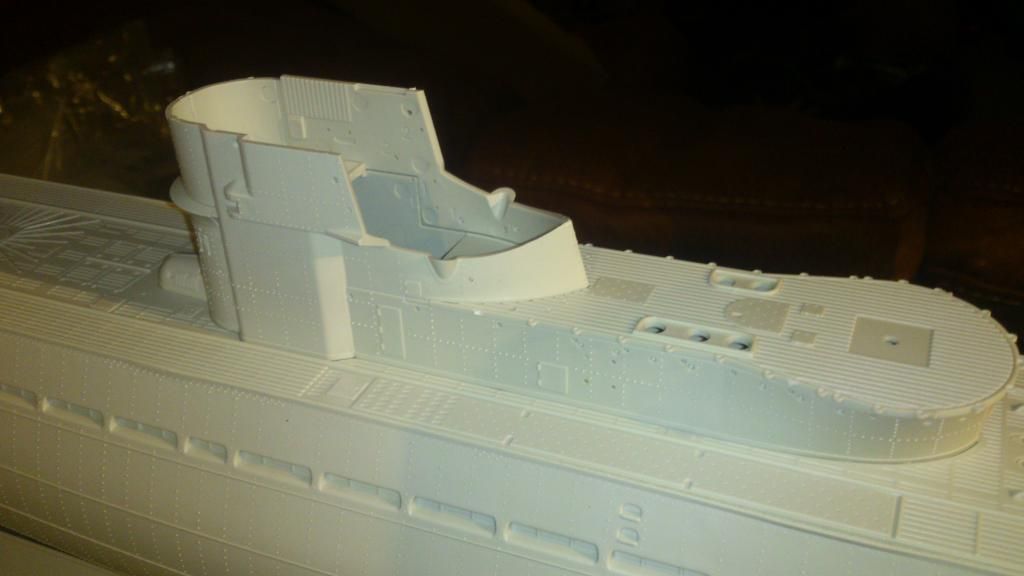

Anyway, some pictures. Please note I still have some sanding and gap filling to do but now the conning tower is test fitted, its starting to take shape and looks good on the window sill.

Part of the Propeller assembly (notice the gaps, ewwww

More gaps that need filling

A bit over zealous with the filler :S will sand that back tomorrow me thinks.

Propellors and rudders (one of the rudders pinged off into the nether somewhere, will have to dig that out at some point

Conning tower test fitted (note the lack of detail on the decking. The wood stuff looks vastly superior from pics I have seen)

Overall progress shot (please excuse the mess. Small house + baby = dad who is to lazy to clear up when theres a u-boat to be built.)

Also been practising with the air brush in preperation for painting this bad boy