| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2015/01/14 07:05:49

Subject: Designing models for 3D printing

|

|

Stalwart Tribune

|

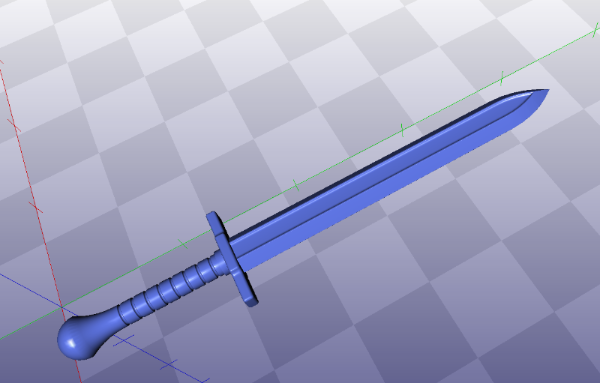

Recently I finished a course learning to work with Solidworks and found myself with a bit of skill for CAD.

Now I've been playing miniature games for about 10 years now and converting for about 6 of that. Now for the first time I find myself with access to CAD software that can create print ready models and boy am I excited to start.

Fire Break is a new tumblr that I've set up for my modeling and 40k junk.

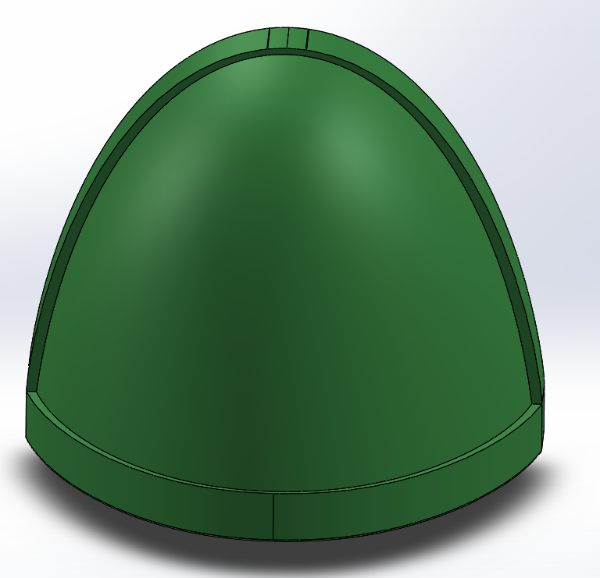

I don't really have a ton up there right now but it's growing as I'm learning. Right now I'm working with marine ideas due to their simplicity of design. Eventually I'll translate some of my old 3d tau designs to proper printable files.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/14 08:07:48

Subject: Designing models for 3D printing

|

|

Homicidal Veteran Blood Angel Assault Marine

|

SolidWorks, nice. I dabbed around with that a bit when I was still doing 3D modeling. Brilliant piece of kit, but it sure is a high-end engineering application. Damn, you can even apply wind-tunnel atmospheric stress testing to your model...  I'm more of a 3D Studio Max man myself.

If your aim is 3D printing, just make sure that your models are fully 'water-tight', but that shouldn't be too much of a hassel, considering SolidWorks surface recognition.

The sword looks good though, good stuff.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/14 10:32:40

Subject: Designing models for 3D printing

|

|

Stealthy Grot Snipa

|

Have you printed anything as of yet?

I am looking to take a step into the 3D printing world in the next few months, but the route I thought i'd have to take was;

3D print master

File/touch-up

Cast in resin

The reasons being that;

A) its still not cost effective to print all the models?

B) the resolution achievable even by the highest standard printers still isn't fantastic?

Whats your take? Where do you plan to go with this?

|

Favourite Game: When your Warboss on bike wrecks 3 vehicles simply by HoW - especially when his bike is a custom monowheel.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/14 17:47:50

Subject: Designing models for 3D printing

|

|

Stalwart Tribune

|

Solar Shock wrote:Have you printed anything as of yet?

I am looking to take a step into the 3D printing world in the next few months, but the route I thought i'd have to take was;

3D print master

File/touch-up

Cast in resin

The reasons being that;

A) its still not cost effective to print all the models?

B) the resolution achievable even by the highest standard printers still isn't fantastic?

Whats your take? Where do you plan to go with this?

Well right now I and an associate use 3D printing via Shapeways to produce prototypes. Their higher grade resolution still requires a bit of work with a hobby knife, or emery boards to smooth out but it's very minor.

After prototyping the model is disassembled if necessary, typically via either a bone saw (if curf is not an issue) or jewelers saw (if it's a precision job). Then we move on to resin casting the item.

We've already done this with a pair of models designed on a different program and have been successfully turned into what basically amounts to a garage kit.

Since Solidworks can save directly to STL file (which is what the printing companies I know ask for) and since It's an engineering program I can design in specific measurements, knowing exactly how big or small my piece is.

Your expected route is essentially the same as mine

Solidworks

Zbrush

Print

Cast

I'm lucky to snag access to this software and finally able to work along side my friend who's working in Zbrush. We figure he'll handle organics and flow, and I'll handle tech.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/14 18:51:51

Subject: Designing models for 3D printing

|

|

Stealthy Grot Snipa

|

Haha! thats awesome, you sound like your about a few months ahead of me and my friend  only difference is we are pooling together to snag a mid-high end printer between us. I plan on doing the same as you guys, while he has a few other ventures in mind.

i'd absolutely love to see photos of a full job, as in of the 3D print you get back and of your resin casts  solidworks is a nice bit of kit, very high end for your needs but glad your getting on with it  think im gona start with google sketchup and go from there.

|

Favourite Game: When your Warboss on bike wrecks 3 vehicles simply by HoW - especially when his bike is a custom monowheel.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/15 04:02:59

Subject: Designing models for 3D printing

|

|

Stalwart Tribune

|

Solar Shock wrote:Haha! thats awesome, you sound like your about a few months ahead of me and my friend  only difference is we are pooling together to snag a mid-high end printer between us. I plan on doing the same as you guys, while he has a few other ventures in mind.

i'd absolutely love to see photos of a full job, as in of the 3D print you get back and of your resin casts  solidworks is a nice bit of kit, very high end for your needs but glad your getting on with it  think im gona start with google sketchup and go from there.

Glad to hear you at least have a plan. Fair bit to note though unless you guys are spending about 20 grand, you're going to need to put quite a bit of work into the printed minis before they'll be ready for cast.

Warning though, do not try to use google sketchup for anything other than a learning process. I tried that first and found out the hard way that it is not a solid geometry program. Everything produced by it end up as hollow like paper models. Also it has serious difficulties converting to STL or OBJ files.

That said Fire Break is updated folks, I got a few more pics up there of the last weapon modified, wasn't quite happy with the cross section of the blade so redid it and added detail to the hilt.

Hope you folks start vising the blog and follow me for further updates. I promise new weapons soon.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/15 04:36:48

Subject: Designing models for 3D printing

|

|

Longtime Dakkanaut

|

Lots of people use Sketch Up every day to produce 3D models for printing. You can export directly to STL, and there are several scripts for Sketchup that allow you to evaluate the model for printing within the program (checking for holes and what not...).

I would be willing to wager that the vast majority of 3D modelers don't actually use a solids modeler, and instead use a polygonal modeler (like Sketch Up). In fact, for the STL format, polygons are the way to go...it doesn't understand solids, only faces and vertices (like a paper model). Same goes for OBJs for that matter, though there is limited support for splines in those.

By working in polygons from the start, you can see problem areas as you work (facets on curves). These you won't see and are often not known by many users (some even believe them to be print artifacts). You can control them to some extent through the export settings from within the solid modeler - but you don't have full control over the tessellation that you have using a polygonal modeler. This may not be noticeable with smaller items - but when you get into big things - it can be the difference between 500,000 polygons and 500,000,000 polygons. When it comes to processing those two files to actually create the print file...that can cost you a day waiting for it to process the file to create the gcode for the printer.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/15 05:44:45

Subject: Designing models for 3D printing

|

|

Stalwart Tribune

|

Sean_OBrien wrote: Sean_OBrien wrote:Lots of people use Sketch Up every day to produce 3D models for printing. You can export directly to STL, and there are several scripts for Sketchup that allow you to evaluate the model for printing within the program (checking for holes and what not...).

I would be willing to wager that the vast majority of 3D modelers don't actually use a solids modeler, and instead use a polygonal modeler (like Sketch Up). In fact, for the STL format, polygons are the way to go...it doesn't understand solids, only faces and vertices (like a paper model). Same goes for OBJs for that matter, though there is limited support for splines in those.

By working in polygons from the start, you can see problem areas as you work (facets on curves). These you won't see and are often not known by many users (some even believe them to be print artifacts). You can control them to some extent through the export settings from within the solid modeler - but you don't have full control over the tessellation that you have using a polygonal modeler. This may not be noticeable with smaller items - but when you get into big things - it can be the difference between 500,000 polygons and 500,000,000 polygons. When it comes to processing those two files to actually create the print file...that can cost you a day waiting for it to process the file to create the gcode for the printer.

Fair point, I'll admit to having some bad experiences with sketchup so take my stuff with a hand full of salt. Again I'm an amature in the 3D end, and more of a traditional engineering design and marketing guy.

Since I have a partner with Zbrush he simply uses the decimate tool until the model is low enough to facilitate quick printing, But yeah I can see your point.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/15 12:28:47

Subject: Designing models for 3D printing

|

|

Stealthy Grot Snipa

|

Some good info posted here

I am aware that i will have to put some work into the models after printing, i do quite a bit of scratchbuilding, so certainly not shy of a little modelling work  Primarily going to start with much larger objects to guide my way through until i eventually move down to smaller stuff. As I play orks I am also not too worried about perfection, something that I think will sit well in garage 3D printing and garage Casting

Looking over your blog a few questions Mr Carabine;

The hand, it appears to be made of ball joints and cylinders, is this so you can allow movement within the program? So you can basically create any hand position from the original and then print as such?

Also I see like little grooves and holes? what are they for?

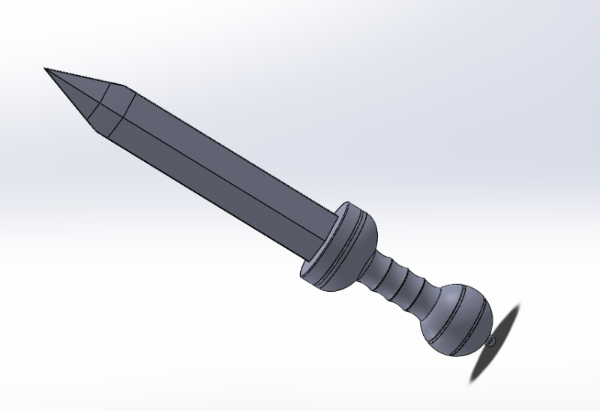

Your gladius, I really like the slimmed version, but in truth I also enjoy the broader version. I think you should most definitely print both!  I feel the broader version seems much more instantly recognisable as a gladius. but i think its hard to tell whether it would suit a model without a trial

|

Favourite Game: When your Warboss on bike wrecks 3 vehicles simply by HoW - especially when his bike is a custom monowheel.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/17 23:18:24

Subject: Re:Designing models for 3D printing

|

|

Stalwart Tribune

|

Whelp the blog's updated again now folks head on over to see what's in store next. Link as always Fire Break

And to answer questions about the gladius, I've heard mixed opinions on the blade breadth and I'll probably end up printing both.

The hand IS indeed designed so I can manipulate it into any position I want. Unfortunately as I have had some poor luck doing ball and socket joints I have used hinge joints here. The holes were originally for axles until I realized the program didn't need them, just needed the holes to act as rotation markers. The hand still has a long way to go before it's done. I still need to adjust individual finger lengths and add a thumb and a wrist.

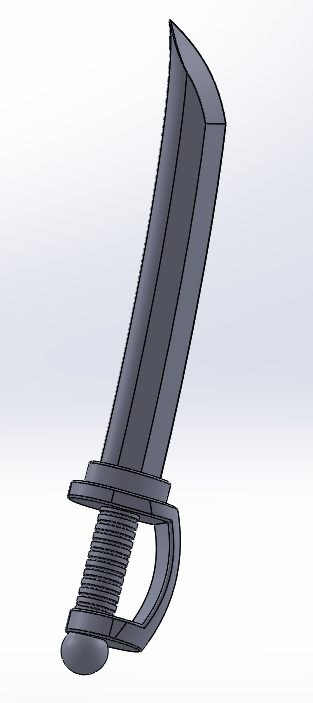

Probably going to be working on a nice saber next.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/19 23:13:58

Subject: Re:Designing models for 3D printing

|

|

Stalwart Tribune

|

Aaaand here we go, a brand new saber for marine hands.

I'm gonna be working on a spear or hammer next I think, not quite sure yet. So stay tuned and feel free to suggest ideas.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/01/20 08:17:42

Subject: Designing models for 3D printing

|

|

Trustworthy Shas'vre

|

Stuff looks good. Love the gladus - eventually I am going to work on my roman theme army...

One thing really missing are better arm options for custom poses and holding weapons (marines).

Finding out stretched arms to put weapons on, or a left arm that is not in the same "hold your bolter" pose.

thanks for sharing.

|

DavePak

"Remember, in life, the only thing you absolutely control is your own attitude - do not squander that power."

Fully Painted armies:

TAU: 10k Nids: 9600 Marines: 4000 Crons: 7600

Actor, Gamer, Comic, Corporate Nerd

|

|

|

|

|

|

|