| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2016/01/15 05:43:04

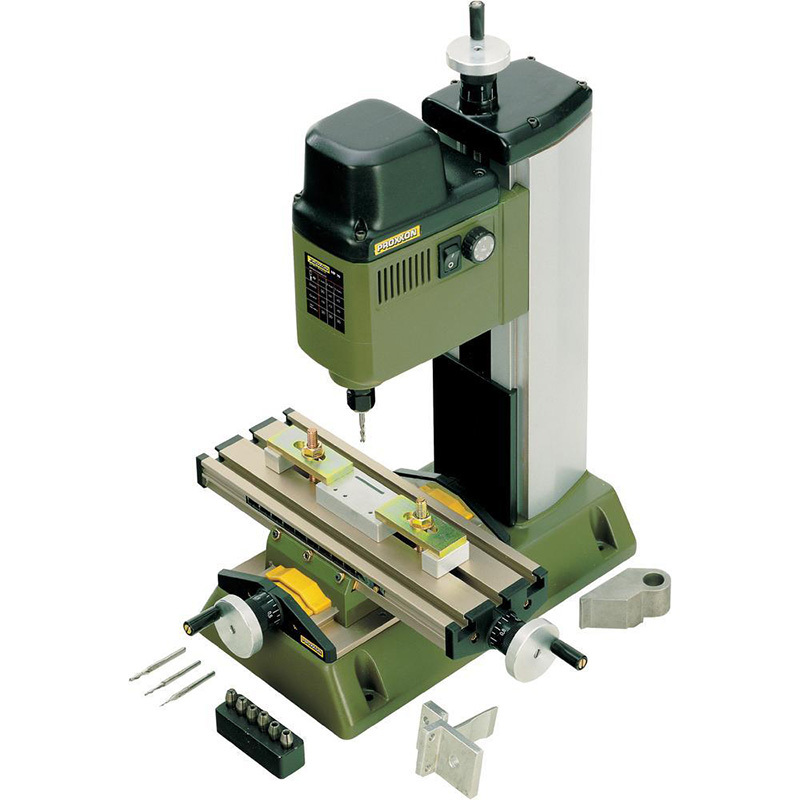

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

Has anyone had any experience with a Micro Mill, such as a Proxxon MF70? My situation is this: a friend of mine wants a good bench top drill press like the Proxxon one that I have (and love), and I'm considering selling mine to him and picking up a Proxxon MF70. For those unfamiliar but are interested, the difference between a mill and a drill press is that a mill has bearings that allow it to bear forces along the X and Y axis as well as the Z -- so instead of just being able to drill up and down, you can drill down, and then cut through the material, the way you would with a router. There are some obvious advantages like being able to create slots (or drill them out, like in a melta-gun) as well as round holes. You can also hook them up to a PC and run a little CNC setup, using a computer to etch onto a surface for you based on your design. If you try to do this kind of work with a drill press, you'll ruin the drill press, because it's not designed to support lateral pressure. My questions are: 1. Is there any disadvantage in hobby use with an end mill, instead of a drill press? 2. the current drill that I has a range of 1800 RPM, 4800RPM, or 8000 RPM (by changing the belt position). Is there an advantage or disadvantage of the 5,000-20,000 RPM (continuous) range that the MF70 runs? Will I ever miss 1800 RPM? I don't use it, but I'm hardly an expert. Do the high RPMs serve any purpose in terms of hobby and cutting into softer materials? 3. The XY table that comes with the MF70 looks really useful for hobby. Even the Z-axis control looks useful, as the 1 rotation = 1mm sounds very precise. Do you know if it's *actually* very precise, or is this just something that looks good on paper? 4. The drill press has a lever; the mill only has a dial to control the Z axis. Is that something really useful that I will miss? 5. Are there any other micro mills I should consider? I am very tempted, because basically, the drill + the XY table is almost as expensive as the mill. And I'd love the XY table, because it's damn hard to line up things like each barrel of an autocannon on a vise with the drill press. But I have never used a mill, and I don't know if I'm just making trouble for myself. Thanks in advance!! This is the unit I'm looking at:

|

|

This message was edited 1 time. Last update was at 2016/01/15 05:49:45

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/15 08:48:46

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Grizzled Space Wolves Great Wolf

|

I don't know about that mill specifically but in general...  Talys wrote: Talys wrote:1. Is there any disadvantage in hobby use with an end mill, instead of a drill press?

You can drill with end mills, particularly if the material is soft. The end mills will tend to wander though and I've forgotten the name of them but you need end mills where the cutting edges go all the way to the center of the bit. You're usually better off using a slot mill if you want to drill. Or you can just put a drill in your mill. It SHOULD come with a chuck that will let you mount drill bits. I usually only use an end mill or a slot mill to drill a hole if I want something flat bottomed. I imagine if you want to drill brass it'll complain more than plastic, I've never tried. I'd always avoid using an milling bit to drill a hole in steel. 2. the current drill that I has a range of 1800 RPM, 4800RPM, or 8000 RPM (by changing the belt position). Is there an advantage or disadvantage of the 5,000-20,000 RPM (continuous) range that the MF70 runs? Will I ever miss 1800 RPM? I don't use it, but I'm hardly an expert. Do the high RPMs serve any purpose in terms of hobby and cutting into softer materials?

Just look up the cutting speed of the materials you might want to cut and calculate the RPM you'll need. If you're using large diameter bits in material that likes a lot cutting speed, you'll want lower RPM. If you're using small diameter bits in material that likes a high cutting speed, you'll want higher RPM. At a guess I'd say 5000 will be fine for plastic and small holes in brass, but may be too fast if you want larger holes in brass. Best just to look up the cutting speeds of the material and calculate it. Googling "cutting speed calculation" and you should be able to figure it out. 5000 to 20,000 almost sounds like a dremel/rotary tool motor  3. The XY table that comes with the MF70 looks really useful for hobby. Even the Z-axis control looks useful, as the 1 rotation = 1mm sounds very precise. Do you know if it's *actually* very precise, or is this just something that looks good on paper?

I can't speak for that mill specifically, but in general the way mills work is accurate. It depends how much slop there is in the bed and the gear that drives it. EDIT: Also if the bed can be locked, I'm not sure if that one can be locked or not. 4. The drill press has a lever; the mill only has a dial to control the Z axis. Is that something really useful that I will miss?

Is it the bed that moves up and down or the head? I've never used a mill that doesn't have a lever, I could imagine it'd be a bit more annoying when using it as a drill as you typically want to make several small plunges when drilling a hole to avoid heating things up too much. Most mills have a lever that you set the depth for, so you pull the lever and it goes to the set depth. I guess there's nothing you MUST have a lever for, especially if you're only cutting plastic. 5. Are there any other micro mills I should consider?

No idea, I usually just use the big ones at work if I need a mill

|

|

This message was edited 2 times. Last update was at 2016/01/15 08:58:06

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/15 09:08:12

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

@Skink - Thanks for your thoughts, since I have ZERO experience with a mill  First of all, this one is *tiny*. It's the size of a jeweler's drill -- the whole thing only weights 15 lbs, to give you an idea. AllSeeingSkink wrote:Or you can just put a drill in your mill. It SHOULD come with a chuck that will let you mount drill bits. I usually only use an end mill or a slot mill to drill a hole if I want something flat bottomed. I imagine if you want to drill brass it'll complain more than plastic, I've never tried. I'd always avoid using an milling bit to drill a hole in steel.

It comes with collets, but it has an inexpensive chuck available to it that everyone seems to prefer. And yeah, I was going to use drill bits  I think the vast majority of what I'll be cutting into is plastic and resin, but I wouldn't discount the kinds of metal that we encounter in hobby. For example, pinning a metal model. Shudder. But they're pretty soft metals. I guess it's possible to imagine brass, but I don't think so. AllSeeingSkink wrote: At a guess I'd say 5000 will be fine for plastic and small holes in brass, but may be too fast if you want larger holes in brass. Best just to look up the cutting speeds of the material and calculate it. Googling "cutting speed calculation" and you should be able to figure it out. 5000 to 20,000 almost sounds like a dremel/rotary tool motor

Okay, great... thanks!  I have a big size drill press for putting holes in anything large, anyhow. This is really primarily for tiny holes like bolters and autocannons with precision; I'm just dreaming of things I could possibly mill for hobby, like slots in pipes and that kind of thing. I will try my google-fu to check materials and drill speeds, good idea! AllSeeingSkink wrote:I can't speak for that mill specifically, but in general the way mills work is accurate. It depends how much slop there is in the bed and the gear that drives it. EDIT: Also if the bed can be locked, I'm not sure if that one can be locked or not.

Hmm.. Maybe I'll ask Proxxon that. I own one of those cross slide vise thingies right now (a drill press vice where there are controls for X and Y), and the (cheap) thing (piece of junk) is totally useless, because the X and Y are not perpendicular. Therefore, if it's a little off in the X direction, and I give it a little turn, the X is lined up, and the Y is off =X It might work for big holes in wood, but it's horrible for lining stuff up for hobby. AllSeeingSkink wrote: I've never used a mill that doesn't have a lever, I could imagine it'd be a bit more annoying when using it as a drill as you typically want to make several small plunges when drilling a hole to avoid heating things up too much. Most mills have a lever that you set the depth for, so you pull the lever and it goes to the set depth. I guess there's nothing you MUST have a lever for, especially if you're only cutting plastic.

This is one of the things that I'm kind of worried about :X Proxxon actually has a small mill with a lever (in addition to Z dial); the problem is... it's 3 times more expensive. And I don't like my autocannons THAT much LOL. Thanks a bunch Skink, and I'll report back if I learn anything new. Or buy it!

|

|

This message was edited 1 time. Last update was at 2016/01/15 09:13:01

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/15 10:37:52

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Incorporating Wet-Blending

|

How on earth are you going to drill bolter barrels with this thing (i want one)

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/15 18:01:28

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

kb_lock wrote:How on earth are you going to drill bolter barrels with this thing (i want one)

No different than a drill press. You put the bolter in a vise, bring the drill bit within a few millimeters of the bolter, and then position the vise precisely using the X-Y table (every full rotation on the XY table is 1mm, so you can move it very accurately). Right now, what I'm missing is the X-Y table, so I must position a vise manually. The thing is, the proxxon table plus a proxxon drill (not a mill) is almost as much money as a mill including the identical table. Positioning it manually *does* work, and it's okay for single-barreled weapons; it's just not ideal for multibarreled weapons, where precise alignment makes a big difference. Even with something like a storm bolter, if one of the two holes is a little off, it looks awful. If you have a good drill and a decent vice, once you line things up, when you move the drill down, it will be *exactly* where you want it, leaving with a perfectly drilled out weapon. The reason single-barreled weapons are not a big deal is because if the hole is slightly off (we're talking fractions of millimeters here), you can just put on a slightly larger bit and drill a bigger hole to cover up your mistake. 0.2mm is very noticeable when it's a hole that's off center, but an extra 0.1mm to the radius of a bolter barrel compared with 9 other models? Nobody will ever be able to tell even if you hold the model up to your nose. But you can't do that if there's 6 holes right beside each other, because if one barrel is larger than another, it's very noticeable. The problem with drilling out barrels with a pin vise is that it's easy to have the pin vise not perfectly parallel to the gun, resulting in the hole being slightly too large and being very slightly off center. Again, not a big deal when it's one hole (because you can fix it easily), but more of an issue with multibarreled weapons, if you're fussy. Also, it's very hard to drill out horizontal slots (like meltaguns) from the side with a hand tool.

|

|

This message was edited 2 times. Last update was at 2016/01/15 18:06:54

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/16 03:53:29

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Grizzled Space Wolves Great Wolf

|

I would have imagined it would be a pain in the arse to clamp most weapons to drill them in a mill as most GW weapons don't have flat sides you can clamp on to. You'd have to make a little jig for each one. It doesn't matter if your mill can drill two holes 4mm apart within 0.1mm accuracy if you can't clamp them in place with better than 5 degree accuracy. I suppose you could use the mill to machine a jig out of acrylic (or other solid block of plastic). I'm not sure how realistic such an endeavour would be. It's the size of a jeweler's drill -- the whole thing only weights 15 lbs, to give you an idea.

Yeah I don't know then, the mills I use are all "full scale" ones, probably starting at about 2000lbs  If it's small and light my concern (which may not actually be a problem) would be that the thing isn't stiff enough (traversing mechanisms have slop, the head having a bit of slop, the beds being rigid enough). The thing is, the proxxon table plus a proxxon drill (not a mill) is almost as much money as a mill including the identical table.

Well, a drill is just a cut down mill essentially  In general the only reason to use a drill over a mill is it's typically easier/quicker to clamp pieces in to a drill press and easier/quicker to clean up when you're done. I guess the question is just whether the proxxon is a quality machine or not, and that I can't answer just by looking at it. I don't have any real experience with mini mills because I just use the big ones at work even when I'm working on little stuff, as long as I can clamp it in and find a head small enough to hold my bit, there's no real problem machining a half inch piece of plastic on a 5 foot bed

|

|

This message was edited 1 time. Last update was at 2016/01/16 03:54:22

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/16 19:22:54

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

AllSeeingSkink wrote:I would have imagined it would be a pain in the arse to clamp most weapons to drill them in a mill as most GW weapons don't have flat sides you can clamp on to. You'd have to make a little jig for each one. It doesn't matter if your mill can drill two holes 4mm apart within 0.1mm accuracy if you can't clamp them in place with better than 5 degree accuracy.

I suppose you could use the mill to machine a jig out of acrylic (or other solid block of plastic). I'm not sure how realistic such an endeavour would be.

I have a few hobby-sized vices for the task  For weapons that have an almost-flat side (like a bolter), I use a small, steel precision vise. For funny-shaped objects, I have a vice that has double-sided foam tape on both sides, and just squeeze the odd-shaped object tightly. For really weird shaped objects, I have a hobby vice with soft rubber jaws, but I don't like it as much, as it has a little bit of play.

Even with the oddest-shaped weapons, usually, there's *some* point of the weapon where there's a good grip.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/17 02:53:01

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Grizzled Space Wolves Great Wolf

|

Yeah I wasn't meaning that you wouldn't be able to clamp it at all, rather getting it square in the clamp. The mill will drill 2 holes in a storm bolted exactly the number of mm apart that you want, but if you can't align the storm bolted precisely with either the X or Y axis you might as well just be doing it on a drill press as it comes down to the accuracy of your eye either way.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/17 04:35:50

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

Ahh I see what you mean. No, that's not a big deal, generally -- the issue for me is always lining it all up, and not having it shift a tiny bit.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/19 18:16:40

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Fixture of Dakka

|

So, after contacting Proxxon and receiving a copy of the manual for the MF70, I decided to abandon the mill idea.

The main reason is that the distance between the spindle and the table is only 2.75" (70mm) which would be very restrictive for larger models. The dial for Z-axis with no lever would probably be a little annoying too.

Thanks for all your input, Skink. I may still consider a different mill in the future!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/19 19:32:27

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Regular Dakkanaut

|

|

|

This message was edited 1 time. Last update was at 2016/01/19 19:34:32

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/01/19 19:49:15

Subject: Proxxon MF70 or other Micro Mill Question

|

|

Incorporating Wet-Blending

|

I'd never actually considered using a tactical marine as a vice before

|

|

|

|

|

|

|

|