| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2015/03/23 22:54:38

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Heya. Honest wasnt sure if this fits in P&M but giving it a go.

Im having the urge to redo my table as it was kinda built like gak

SOOO i have hit a wall concerning the lenght of the table.

The table is going to be overall 104" x 56" ish with a 4" frame around the whole thing so that i can inset boxes or a felt covered hard board inside perfectly as a 4x6-8 table.

I want to make the total inner dimensions as 8feet to facilitate a 2x4 utility box for rolling stuff in or cup holders etc etc. but the issue is plywood doesn't come in lengths greater than 10 feet around where i am

Im not sure if i want to just sacrifice the idea of 8feet and go with 7 feet and have a 1x4feet utility box or if i should make a lap joint and extend some pieces to the right length. primary issue is that i will be building this whole thing with the basic of basic tools (so drill and a circular saw.

im trying to avoid hardwood boards as they are going to kill my project budget :/

Any advise would be great.

|

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/23 23:01:33

Subject: Table making. any woodworkers out there?

|

|

Dakka Veteran

South Portsmouth, KY USA

|

96"x48" = 8'x4', I would make that the inside marking for your "bumpers" so that you could lay in your terrain tiles.

Sounds like you have enough space with a 104"x56" surface.

Make sure you build a good frame underneath as plywood is wont to warp.

You should have enough space for a nice lip all round.

|

Armies: Space Marines, IG, Tyranids, Eldar, Necrons, Orks, Dark Eldar.

I am the best 40k player in my town, I always win! Of course, I am the only player of 40k in my town.

Check out my friends over at Sea Dog Game Studios, they always have something cooking: http://www.sailpowergame.com. Or if age of sail isn't your thing check out the rapid fire sci-fi action of Techcommander http://www.techcommandergame.com

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/23 23:04:48

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

That Frame is the issue though in that the materials i wanted to use dont come in the lengths that i need

so im considering shortening it so i dont have to do massive amount of hand work. or doing the work with a lap joint of some sort to ext the table to the full length.

|

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/23 23:09:53

Subject: Table making. any woodworkers out there?

|

|

Dakka Veteran

South Portsmouth, KY USA

|

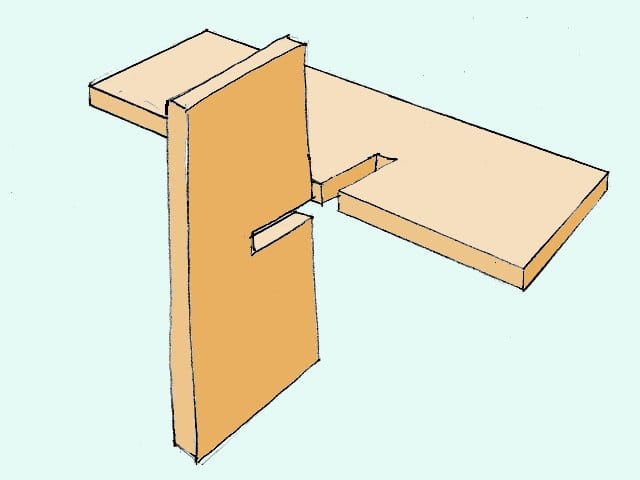

I wouldn't worry about a lap joint underneath, quarter off your length and build your frame according to section, use your crossbeams to tie up the butts.

|

Armies: Space Marines, IG, Tyranids, Eldar, Necrons, Orks, Dark Eldar.

I am the best 40k player in my town, I always win! Of course, I am the only player of 40k in my town.

Check out my friends over at Sea Dog Game Studios, they always have something cooking: http://www.sailpowergame.com. Or if age of sail isn't your thing check out the rapid fire sci-fi action of Techcommander http://www.techcommandergame.com

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/24 18:32:18

Subject: Re:Table making. any woodworkers out there?

|

|

Infiltrating Broodlord

|

I cannot find the plans I used to build my table but this guy looks like he used the same ones.

http://www.corehammer.com/building-a-game-table-part-two/#more-1617

http://www.corehammer.com/building-a-game-table-part-three/#more-1787

If you look at this image you can see they have the game board and an empty space that you can make into a pocket for dice rolling or model storage.

On my table the upper framing is attached to the legs higher up, this is because i have double sided inserts that i use for gaming on. I have one that is 4x6 that has black felt for X-Wing on one side and the GW grass mat for other table top gaming. I also have a 2x4 section that has green felt on one side; to expand the table to 4x8, and floor tiles on the other as model storage.

My inserts are made from 1x3s sandwiched between some thin plywood which i got Home Depot to cut to the exact sizes i needed for free. This made hauling the thin sheets easy in my 6ft bed while the 2x4 and 2x6 hung off the back.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/24 18:36:22

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Thats nearly the same table i built already but with the top being flush to the edge (because i got lazy  )

Im trying to keep weight down as well which is why i wanted to rip the whole thing out of 1/2" plywood.

If i do it right i should be able to build nearlly the whole thing with two sheets of 4x8 for like 30 bucks a sheet which isnt bad.

|

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/24 21:57:58

Subject: Table making. any woodworkers out there?

|

|

Fixture of Dakka

|

Is there a reason that you want to make one 8x4, instead of two 4x4 (in approximate sizes)?

I personally find two 4x4 to be more useful because I can split them up when the occasion warrants, and it's easier to move around.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/24 22:02:59

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Im trying to put a arm rest lip around the sides

having two 4x4s of the same build will have issues with a lip.

|

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/25 21:19:02

Subject: Table making. any woodworkers out there?

|

|

Shunting Grey Knight Interceptor

|

Desubot wrote: Desubot wrote:Thats nearly the same table i built already but with the top being flush to the edge (because i got lazy  ) Im trying to keep weight down as well which is why i wanted to rip the whole thing out of 1/2" plywood. If i do it right i should be able to build nearly the whole thing with two sheets of 4x8 for like 30 bucks a sheet which isnt bad.

I'll take a picture of my board when I get home, as I think it's close to what you're looking for. That said - I think you're suggesting that you build the whole thing out of half inch plywood. As in, including the "frame" that goes around the playing surface? That's a bad idea. On a normal table, the stability of the whole structure is usually from the surface of the table itself. The legs screw directly into the bottom of that surface, and the "frame" that runs between the legs underneath the surface is mostly there to keep the legs from wiggling. (Simplifying here, obviously. The point is that the surface of a table plays more of a structural role on most tables than on Gaming Tables.) Gaming Tables can be built the same way, but usually aren't. Gaming Tables are usually more like bed frames, with the legs being attached to a stronger frame and the gaming surface resting on "slats" that run from one side of the frame to the other. The rigid gaming surface helps keep the frame at proper 90 degree angles, but doesn't add much more to the stability of the structure. What I'm trying to say is that while the half inch ply might be fine for the "surface" of the table, I'd strongly advise getting some cheap 2x4 or 2x6 boards do go around the board. Again, there are a lot of ways to pull this off, but don't expect plyboard to hold up for long if it's bearing the weight and stress of a 4 foot by 8 foot table. I mean, I'd even recommend pressure treated 4x4 posts for the legs. They're heavy, but they can take a lot of punishment.

|

|

This message was edited 2 times. Last update was at 2015/03/25 21:38:14

Sable Brotherhood - 2000pts Sable Brotherhood - 2000pts

Wraithsight Corsairs - 2000pts Wraithsight Corsairs - 2000pts

Void Angels - 500pts Void Angels - 500pts |

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/25 22:21:58

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

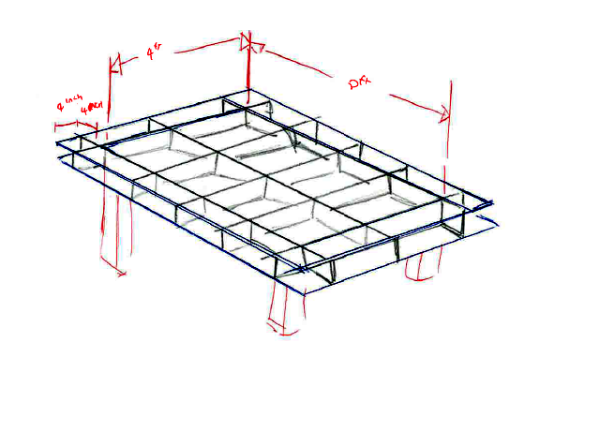

Here is a quick and UGLY layout of what i wanted to do  The idea is to get these 4inch x 1/2 inch slats, cut interlocking groves into them and make a kinda torsion box set up.  Then add on a 4x1/2" frame on the outside on top and below to create cubbies for models and dice. by doing that there will be a 1/4" lip that i can drop a few 2x4 Masonite boards or even a realms of battle board onto the inside Edit: i should be able to do the whole project with nothing but a circular saw and a decent guide rail and clamps. and the final issue comes back to the length of the plywood available. I could do it with pine but im not sure how well it would hold up as well look after staining. as well IIRC its a pretty soft wood and may sag.

|

|

This message was edited 5 times. Last update was at 2015/03/25 22:35:14

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/25 23:02:01

Subject: Table making. any woodworkers out there?

|

|

Fixture of Dakka

|

And that's why you don't want to rely on plywood for all your structural components. It DOES sag when not supported properly. Even thicker plywoods sag noticeably.

Save yourself a lot of heartache down the road, and money in the long run. Use 2x4s (at the very least) for the structure.

|

CHAOS! PANIC! DISORDER!

My job here is done. |

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/25 23:04:12

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Wouldn't ply wood that is basically on its side and at least 4" wide have a decent chance at not sagging in a interlocking grid properly glued and tacked?

I dont think iv ever seen something of that thickness bend besides from some ridiculous weight.

|

|

This message was edited 1 time. Last update was at 2015/03/25 23:04:31

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/26 02:14:31

Subject: Table making. any woodworkers out there?

|

|

Shunting Grey Knight Interceptor

|

I think I owe plywood an apology. I think your plan looks awesome, and when it's braced like that I don't think you'll have any sagging problems. My only concern is that the half inch board will have a problem with all the weight at the connection points to the legs. Fortunately, I have a solution! 2x4s.  Seriously - you said that you're having a hard time finding 8 foot plywood? Well save yourself the hassle, and just go with two 8 foot 2x4s. Your plans have three pieces running the full length of the table - two that will attach to the legs and one in the middle? Just use 2x4s, and you won't have to bother with a piece of plyboard longer than 4 feet. Since the "lip" on the ouside isn't structural, it doesn't matter if you put it on in two peices. Plus, I think that with the added stability of the 2x4s on each outer edge you can get away with scrapping the middle beam. So you can make back any weight issues there by having one fewer piece of wood.

|

|

This message was edited 3 times. Last update was at 2015/03/26 02:16:39

Sable Brotherhood - 2000pts Sable Brotherhood - 2000pts

Wraithsight Corsairs - 2000pts Wraithsight Corsairs - 2000pts

Void Angels - 500pts Void Angels - 500pts |

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/26 15:45:12

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Oh no 8foot long plywood is everywhere (its actually the standard size 4x8feet.)

Problem being that the overall length is greater than 8 feet and i wanted to keep the design simple and clean.

i did however just find 10 feet x 4 feet x 15/32"

So i might not have any more issues with that. except that its unfinished and kinda cruddy looking so il have to think about it. (sheeting plywood implies its pretty fethin low quality)

Now to fully figure out the base.

|

|

This message was edited 1 time. Last update was at 2015/03/26 15:46:09

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/26 15:58:46

Subject: Table making. any woodworkers out there?

|

|

Hellacious Havoc

|

I built my table 8x4ft and have used it as a 6x4, 8x4 and have had 2 games at 4x4 with out any issues. I think 8x4 is the way to go personally.

This is my build thread if you are interested in taking a look and if you want any advice or have any questions I am happy to try my best to answer.

http://www.dakkadakka.com/dakkaforum/posts/list/627642.page

I still haven't gotten around to finishing it completely, still have one of the legs to stain and seal.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/26 16:16:51

Subject: Table making. any woodworkers out there?

|

|

Legendary Master of the Chapter

|

Yep I saw that thread and even posted in it too IIRC  Mine has to be a sit and stand table for war hammer and RPG/board game nights. Which is why i only wanted to do about a 1/2" ish lip instead of your honking 4ish inch dept  would be nice though as dice seems to like flying off into the carpet  Edit: Just found a plywood speciaty store near by If this works out il probably spend a weekend making it and probably post a tut.

|

|

This message was edited 1 time. Last update was at 2015/03/26 16:18:06

Unit1126PLL wrote: Unit1126PLL wrote: Scott-S6 wrote: Scott-S6 wrote:And yet another thread is hijacked for Unit to ask for the same advice, receive the same answers and make the same excuses.

Oh my god I'm becoming martel.

Send help!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/27 17:38:57

Subject: Table making. any woodworkers out there?

|

|

Fixture of Dakka

|

Desubot wrote: Desubot wrote:Im trying to put a arm rest lip around the sides

having two 4x4s of the same build will have issues with a lip.

I see! Please share your finished table

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/27 19:17:10

Subject: Table making. any woodworkers out there?

|

|

Lone Wolf Sentinel Pilot

|

One thing to keep in mind since they were used in the link above; be very wary of using 4x4 posts inside. All current 4x4's are pressure treated and designed to be used outdoors. Some of the chemicals used in pressure treated lumber include arsenic, which can leach out. So I can't recommend using these indoors.

If you build the table structure correctly you really don't need the 4x4's anyway, 2x4s or 1x4s will work perfectly fine. Just make sure to frame your table out and you will be in good shape.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/27 23:22:06

Subject: Table making. any woodworkers out there?

|

|

Hellacious Havoc

|

Todosi wrote: Todosi wrote:One thing to keep in mind since they were used in the link above; be very wary of using 4x4 posts inside. All current 4x4's are pressure treated and designed to be used outdoors. Some of the chemicals used in pressure treated lumber include arsenic, which can leach out. So I can't recommend using these indoors.

If you build the table structure correctly you really don't need the 4x4's anyway, 2x4s or 1x4s will work perfectly fine. Just make sure to frame your table out and you will be in good shape.

You can get 4x4s that are not outdoor pressure treated lumber, but be prepared of a steep price tag. I will second that they should just be avoided all together.

|

|

This message was edited 1 time. Last update was at 2015/03/27 23:44:00

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/28 01:15:47

Subject: Re:Table making. any woodworkers out there?

|

|

Gargantuan Gargant

|

I thought about building a 4x8 table with an arm rest and got frusterated trying to come up with a good design that would supply ample space for books and dice and not be so wide that reaching the middle of the table would be difficult.

This design ended up eating 4 4x8 sheets to make, but resulted in a ton of storage space.

The top, gaming, surface is 4x8, the middle is 5x8, and the bottom shelf is 4x8.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2015/03/29 16:02:31

Subject: Table making. any woodworkers out there?

|

|

Longtime Dakkanaut

|

Desubot wrote: Desubot wrote:Heya. Honest wasnt sure if this fits in P&M but giving it a go.

Im having the urge to redo my table as it was kinda built like gak

SOOO i have hit a wall concerning the lenght of the table.

The table is going to be overall 104" x 56" ish with a 4" frame around the whole thing so that i can inset boxes or a felt covered hard board inside perfectly as a 4x6-8 table.

I want to make the total inner dimensions as 8feet to facilitate a 2x4 utility box for rolling stuff in or cup holders etc etc. but the issue is plywood doesn't come in lengths greater than 10 feet around where i am

Im not sure if i want to just sacrifice the idea of 8feet and go with 7 feet and have a 1x4feet utility box or if i should make a lap joint and extend some pieces to the right length. primary issue is that i will be building this whole thing with the basic of basic tools (so drill and a circular saw.

im trying to avoid hardwood boards as they are going to kill my project budget :/

Any advise would be great.

Typical long winded post to follows...

Read the idea, sounds like a plan - though in general, more work than needed.

Consider two sheets of 1/4" plywood - one sheet of 1 1/2" insulation, 3 1x2 hardwood 8' long. Ball park price should put you around the same as your 2 sheets of 1/2" plywood (or close to it). You will also need a good foam adhesive (Glidden Gripper is what I prefer for this sort of thing). Trim your foam to be about 1 1/2" shorter and narrower than your plywood. They will form a frame around the foam and provide a location for mechanical fasteners to attach the arm rests. Assemble the frame, check the fit around the foam. Apply adhesive to your plywood sheets, one on the top, one on the bottom, frame around the foam - tack in place to prevent shifting while the glue dries, weight down with everything heavy that you have.

Once that sheet dries, you can attach your arm rests to the 1x2s - though I would skip the 4x4s on them. Instead, use 1x however wide you want (budget allows) using pocket hole screws into the frame. Screws every 12-16". Add a drop edge to give the rests more weight and resistance to sag.

Choose your legs - in compression, most materials are plenty strong, the issue ends up being one of racking. You can attach them to the drop edge on your armrests to help or you can use mounting plates attached to the table surface itself (try to position them so that 3 out of the 4 holes on the plates catch the hardwood frame). The benefit of the mounting plates is that they allow the use of a threaded leg that can be easily removed for moving and storage. Most big box stores have a few different styles with posts already attached for use in the threaded mounting plates.

It shouldn't stretch your access to tools much at all. Shouldn't bust the budget. Having access to a Kreg (or similar) jig makes the pocket holes much easier to drill - though you can do those by angling the drill by hand (or drilling a guide through some scrap wood).

Belac Ynnead wrote:Gaming Tables can be built the same way, but usually aren't. Gaming Tables are usually more like bed frames, with the legs being attached to a stronger frame and the gaming surface resting on "slats" that run from one side of the frame to the other. The rigid gaming surface helps keep the frame at proper 90 degree angles, but doesn't add much more to the stability of the structure.

What I'm trying to say is that while the half inch ply might be fine for the "surface" of the table, I'd strongly advise getting some cheap 2x4 or 2x6 boards do go around the board. Again, there are a lot of ways to pull this off, but don't expect plyboard to hold up for long if it's bearing the weight and stress of a 4 foot by 8 foot table. I mean, I'd even recommend pressure treated 4x4 posts for the legs. They're heavy, but they can take a lot of punishment.

Most of the reason that game tables are all built the same has more to do with just one or two people who did tutorials, and then a lot of people without much imagination, understanding of materials and needed skills and tools copying those few. The tables aren't bad - but often they tend to be far from good.

There is a reason that you can find examples of 150 year old dining tables with spindle legs and even a huge variety of mid-century modern furniture that is made much lighter than the gaming tables we see being made from construction timbers. Even the vast majority of furniture purchased today (fine or otherwise) is made up using plywood, particle board and surface veneers (not condoning those practices - as often that is craptastic).

Understanding the working properties of the materials being used allow you to design and build something that fits in well in a dining room - as opposed to the basement game room. Using 2x4s to create a skirt for the table works well enough - but 1x2 oak has about the same resistance to deflection as that 2x4 pine. Build up the table with a hardwood veneer plywood - crossmembers to support the leg locations, larger apron to connect the legs to prevent racking, it is now fine furniture that you don't have to worry about taking down every night...because it is nice enough to have Thanksgiving dinner on.

While the specifics will vary depending on the actual materials chosen, something like 1/2" fir plywood (your standard AC plywood from big box stores) can cantilever up to around 10" with a 0.03" per foot deflection. Secured on both edges (with a skirt or other structure) the span goes up to around 24" with the 0.03" per foot deflection with a 20 psf live load. At 16" - the deflection is almost 0 with the same load.

Desubot wrote: Desubot wrote:Here is a quick and UGLY layout of what i wanted to do

The idea is to get these 4inch x 1/2 inch slats, cut interlocking groves into them and make a kinda torsion box set up.

Then add on a 4x1/2" frame on the outside on top and below to create cubbies for models and dice. by doing that there will be a 1/4" lip that i can drop a few 2x4 Masonite boards or even a realms of battle board onto the inside

Edit: i should be able to do the whole project with nothing but a circular saw and a decent guide rail and clamps. and the final issue comes back to the length of the plywood available.

I could do it with pine but im not sure how well it would hold up as well look after staining. as well IIRC its a pretty soft wood and may sag.

Staring to get a bit odd since I am working backwards through the posts. Your spacing may prove problematic with a 1/2" top and the joinery may prove difficult with a circular saw. You can skip on the interlocking grid easily enough - a well glued butt joint will be stronger than a poorly fit lap. Not saying that your lap joints will be poorly fit - but it will be much more difficult to get them snug enough using a circular saw. Your top material choice means that your grid spacing is likely going to need to be 16" on center or so with a live load of 20 psf to achieve near 0 deflection. The bottom skin doesn't need to be 1/2" - 1/4 or even 1/8" is enough. It is acting as the bow string of the box. There are some benefits to it being the same thickness as the top - but minimal in this application. The calculations get pretty complicated, as much of the strength will depend on the strength of your glue joint as opposed to the materials used. Things like the floors for modern cargo aircraft are built in a similar way - but using much, much thinner materials. You can drive a tank on some of them...

For the lengths over 8 feet that you are dealing with - it can be a bit hard to source. Especially using on hand stock through local suppliers. 4x10 and 5x10 plywood are made - but most lumber yards don't keep it on hand. You can special order it easily enough though. A better option for you might be to take a look at 1/4" or 1/8" plywood. You can glue up several sheets to create a larger sheet of thicker material. This helps to avoid the issue of garbage plywood I mentioned below too. The thinner plywood tends to be void free. For gluing it up - alternate your layers so that the joints are separated by a foot or two between layers. Apply an even layer of glue over the whole surface (paint rollers work wonders). Stack up your layers and get the joints as tight as possible. Clamp. For clamping - bags of sand...sheets of MDF...small children... Pile it on. I vacuum bag mine, but that is a bit overkill for a one off project.

Once the glue has set up, you can square up the sheet and finish construction. Since you will probably be painting the surface, you can just use a wood filler on the surface joint - sand and paint. If you wanted a nice wood surface - apply a polymer filler (Bondo is great), sand smooth then do a surface veneer. You can get some really nice veneers in really large sizes for relatively cheap.

Vulcan wrote: Vulcan wrote:And that's why you don't want to rely on plywood for all your structural components. It DOES sag when not supported properly. Even thicker plywoods sag noticeably.

Save yourself a lot of heartache down the road, and money in the long run. Use 2x4s (at the very least) for the structure.

If you are using a cheap plywood - it can be an issue. However, all materials have design limits. Double check your material against the technical information for it - and build as needed. You could build the whole table out of 1/8" Masonite if you like - just need to understand what needs to go where.

A wood of caution regarding plywood though - most of it that you find now...especially in big box stores...is garbage. The adhesive used for laminating is prone to delaminating. Voids on inner plys make mechanical fasteners troublesome (shooting a nail in on edge - even screws and finding there is no wood to actually hold in). The finish faces are so thin that any sort of sanding goes straight through the veneer. I tend to go with a more expensive cabinet grade plywood for these sorts of things ($100+ per sheet versus the $30 or so from the big box stores). Baltic birch (in the funny 5x5 sheets) or a void free like Appleply. For really special stuff, I will lay up my own sheets to the sizes I need.

The plywood product will actually be better than one made out of 2x4s. They really are not much better than the cheap plywood. Knots, case hardening, twists, bows and cups (how they manage to get a 2x4 to cup...). Last fall when framing up my new shop, I sorted through 3 bunks of 2x4s just to get enough that were "reasonably" useable to frame the partition walls. Although you will need fewer of them for the table - you will need them to be better (not hidden behind drywall and braced against other things to pull them straight).

If you have access to a tablesaw - you can pick up 2x6 or 2x8 lumber for just a bit more and rip them to the width you need. The larger lumber are cut from larger trees so the way the grain runs tends to make them less prone to going all wonky. It will also give you nice square edges to work with and you can cut around knots and waney edges.

Desubot wrote: Desubot wrote:Wouldn't ply wood that is basically on its side and at least 4" wide have a decent chance at not sagging in a interlocking grid properly glued and tacked?

I dont think iv ever seen something of that thickness bend besides from some ridiculous weight.

Without any problem at all. Torsion boxes are a solid way to keep weight down - but the cuts do need to be more precise in order to achieve the best results. Whenever I would do thick table tops (4" plus) - they are almost always torsion boxes of a sort. Plywood for the internal bracing works excellent - since it is inexpensive, dimensionally stable and fairly easy to work.

For a proof in concept for those who might be concerned - take a look at materials that are often called I-joists. It is a 2x top and bottom stringer with plywood webbing in between. They (along with glulams and paralams) have largely replaced solid lumber in residential and light commercial floor and roof framing.

Back to the concept though, the key is to make sure your grid is assembled square and straight and ensure all your joints are well glued. While it won't be under a heavy load - if the grid is off kilter a bit, the pressure applied to your stress skins can cause the hole thing to collapse like a house of cards should something unusual happen (stresses when moving the table or someone leaning across the table as opposed to moving to the other side...that is why I keep a push stick handy, both to extend the reach and to whack people who are trying to climb on my tables).

bladeiai wrote: Todosi wrote: Todosi wrote:One thing to keep in mind since they were used in the link above; be very wary of using 4x4 posts inside. All current 4x4's are pressure treated and designed to be used outdoors. Some of the chemicals used in pressure treated lumber include arsenic, which can leach out. So I can't recommend using these indoors.

If you build the table structure correctly you really don't need the 4x4's anyway, 2x4s or 1x4s will work perfectly fine. Just make sure to frame your table out and you will be in good shape.

You can get 4x4s that are not outdoor pressure treated lumber, but be prepared of a steep price tag. I will second that they should just be avoided all together.

Regular 4x4 lumber is pretty easy to find, not even more expensive than treated in many cases. You will likely have to look outside of big box stores like Lowes and Home Depot though - they tend to only keep the green treated and more expensive cedar/redwood on hand. Regular lumber yards though should have Douglas Fir or Southern Yellow Pine in non-treated flavors.

All the same, CCA treatment (the one which uses arsenic) has fallen out of favor for the past 10 years or so. Most the treated lumber you will buy at regular lumber yards will be ACQ (Copper and Ammonia). While I wouldn't recommend you chew on it - the chemicals used in treating lumber now are largely benign for higher level organisms (which would apply to most forum readers).

And of course, with all that said - I wouldn't use 4x4s. They are more likely to develop substantial checks. You can glue up multiple layers of thinner stock to get the same overall thickness - and for bonus points miter the edge joint so that the face grain is the same on all faces. For reduced weight, you can even use something like 1x4 material and build up a box column with them - hollow in the middle, just as strong as solid wood provided your glue joints are done well.

|

|

|

|

|

|

|