| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2016/11/24 16:06:05

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Just got out my second ever airbrush, the first having packed in after about 5 minutes use. Used it on a test model (landspeeder) and at first no paint came out (GW air paint), so I added some vallejo airbrush thinner. Eventually, after playing about with twisty bits etc, I had paint on the way! BUT, it was pooling a lot. Is that because I thinned it too much?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/24 16:53:34

Subject: calling all airbrush aficionados

|

|

Been Around the Block

|

hi, i am an airbrush noobie, but let me check some things -

what AB are you using and do you know the needle size?

what sort of compressor are you using and do you know the PSI you are spraying at? I've found 30 for primer and varnish and 20 for paint fits with my use so far.

i have used the GW air and while they are a bit thick and I've found I just need to give a good quick full blast spray at a piece of paper towel if it gets clogged, I don't thin them (I think theres a way to clear by blocking the tip and spraying also)

For a first test, I would recommend shooting water at a piece of paper, just spray water out of the gun, you can even shoot it at stuff if you want. then you can test shooting paint out of the airbrush but not at a model, draw some shapes on a paper, but probably dont shoot this at random things.

if your paint lands on a model looking a bit wet i think that is correct but it should not be running or pooling.

|

|

This message was edited 1 time. Last update was at 2016/11/24 16:55:33

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/25 00:26:34

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

I have a witmoving sp180k airbrush with a 0.2 needle fitted. I also have 0.3 and 0.5 needles in the box, though I haven't disturbed them yet.

My compressor is a spraymaster cps1001, which I think is set at 40psi.

A very budget focused set up as I don't want to spend a fortune until I know what I'm doing, and I seem to have fallen slightly at the first hurdle lol.

How far should the brush be from the model when spraying? Is there a minimum required distance or something?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/25 00:47:17

Subject: calling all airbrush aficionados

|

|

Been Around the Block

|

The 0.2mm needle might be a bit small for the viscosity/pressure you're using. Try switching to the 0.3mm needle.

For the paint that's already too thin, try mixing in a bit of acrylic medium. Liquitex and Golden brands should be easily available via art stores or Amazon.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/25 13:47:02

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

GW air paint is too thin to begin with?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/25 14:05:26

Subject: calling all airbrush aficionados

|

|

Speedy Swiftclaw Biker

|

I never spray more than 30psi. With a small needle size like that too, you will have trouble.

GW air paints do not need to be thinned unless you are doing OSL or other very fine details.

Did you prime the model?

I do 90% of my painting via airbrush. Not a Next Level or other painting studio quality but not bad.

|

=][= |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/26 18:51:39

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

I did a xenithal prime out of spray cans, though not on the test model - that was just a thick old black base coat. The xenithal base coat has been done on the stormraven, which is what I'm building up to.

So you think I should go up as far as the 0.5 needle at 40psi? Don't much relish the idea of replacing my compressor yet, having barely used the one I have already lol

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/26 19:00:31

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Does it have anything to measure, regulate or adjust pressure?

I just had a google and it says "Type: Piston Compressor, Power: 1/8 HP, Maximum pressure: 2.8bar(40PSI), Air output per min./litres: 13L/min"

Usually a compressor does NOT maintain maximum pressure once air starts flowing, so if there's no regulator and no gauge to read the pressure, goodness knows what it might be.

Paint pooling can be a few things...

1. Paint too thin

2. Pressure too high

3. Spraying distance too close

4. Not moving the brush fast enough (staying in one place too long)

|

|

This message was edited 1 time. Last update was at 2016/11/26 19:01:02

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/26 19:04:56

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

No, it's just a block of plastic with a motor inside, and an on/off switch on the exterior. Got it on account of it being cheap tbh, sounds like that may have been a mistake!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/26 19:23:53

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Yeah it's usually best to go with a compressor that has at least 1/6HP and a regulator. Anything bigger than that will work fine, anything smaller than that without a regulator could be problematic.

It might not be delivering too much pressure because, as I said, compressors don't deliver their MAX pressure when the air is flowing, the rated max pressure is what level they can pressurise a closed container with no airflow.

Try swapping to the 0.3mm nozzle and using a slightly thicker paint and see if that helps. 0.5mm is pretty big for miniatures and is probably overkill if you're not basecoating (and indeed your compressor might struggle to provide enough air to atomise that much paint).

Try being a few inches away from the model and see if you have better control over the pooling and don't stay pointing at one spot for long. It takes multiple "passes" to give a model a decent solid coat of paint, so always keep the airbrush moving.

|

|

This message was edited 1 time. Last update was at 2016/11/26 19:25:49

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/26 23:17:14

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Cool, I'll give it a whirl on my days off - wish me luck!

Just for the sake of asking, how much would a budget version of the compressors with the features you refer to go for?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/29 22:44:24

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

So I've been speaking to the wife, and people have been asking what to get me for Xmas. She's talking about everyone pooling together for a compressor for me.

With that in mind, can anyone recommend a good compressor with regulator and all that jazz?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/29 23:46:27

Subject: Re:calling all airbrush aficionados

|

|

Ancient Venerable Black Templar Dreadnought

|

I bought this guy:

http://www.air-compressor-reviews.net/gmc-syclone-6310-review/

60 decibels is the same noise level of a "normal" conversation, 70 is an arbitrary "irritant" level.

It is a dual piston with a large tank so you will not see any pulsation and will not have to turn on often to refill the tank.

Even a bit of foam around the walls of the compressor would pretty much kill what little noise it makes.

Many people can claim good results with diaphragm compressors but the tank takes out any question of pulsation.

I keep being told the "ideal" is a bottle of Nitrogen, it is dry as heck and takes a while to get through some 1200psi of gas and cheap to fill.

Just need to ventilate well just in case you displace too much normal air.

Regulators are pretty simple to get.

You need a dryer which I think the GMC pump has and I would use another.

I would then get a fine level regulator and get a 0-30psi gauge since the 120psi gauges are pretty much useless for seeing what pressure you are running at.

Anything else is pretty much a matter of preference.

|

A revolution is an idea which has found its bayonets.

Napoleon Bonaparte |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/30 00:19:23

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

That things bloody HUGE!

More interested in something that's small, as quiet as possible, and will do what's needed to do out of the box.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/30 04:58:50

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Yeah you don't need anything that big. The thing with aircompressors is you can always get something bigger and step it down. I don't want to suggest a specific brand of compressor because the one I bought was a brand which I believe is only sold in Australia. Just look for hobby compressors that are at least 1/6HP (125W) and at least 20 litres/min flow rate with an output pressure of at least 40PSI (3 bar) cut in (mine cuts in at 3 bar and out at 4 bar). If you get that, it'll be sufficient. Anything more will work, anything less and you'll be pushing your luck. It might not be enough to paint a car, but it should be fine for painting anything up to the size of a Forge World titan. I personally recommend a tank attached to the compressor, but I've never actually tried one without a tank, I got a tank because it was recommended to me with the idea being it helps cool the air, offers smoother air and less moisture. But it pushes the price up and I have friends who use the exact same model of compressor as me minus the tank and they say it works fine (and I'm not talking some average Joe who doesn't know how to paint, this guy paints competition level scale aircraft models). If you get one without a tank you may end up having to invest in an extra moisture trap. Personally I'd just get one with a tank

|

|

This message was edited 1 time. Last update was at 2016/11/30 04:59:31

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/30 16:48:45

Subject: calling all airbrush aficionados

|

|

Ancient Venerable Black Templar Dreadnought

|

kitch102 wrote: kitch102 wrote:That things bloody HUGE!

More interested in something that's small, as quiet as possible, and will do what's needed to do out of the box.

A possible compromise to not be so "bloody huge" and still do what is needed:

-GMC 3.0 Gallon SYCLONE 3010 Ultra Quiet and Oil-Free (60dB noise)

-CALIFORNIA AIR TOOLS 2050A (I think these guys bought GMC)

-California Air Tools: Light & Quiet 1P1060S Portable (56dB)

-Master Airbrush: TC-20T

-Paasche: D3000R

-Eastwood: 1/6 HP Compressor w/Auto Shut-Off (this is of interest to me since it has a tank and uses a diaphragm pump).

-Badger Air-Brush Co.: Aspire Pro Compressor

-PointZero: Pro Airbrush Air Compressor Twin Piston w/ Tank 1/3 HP

-Senco PC1010 1HP 1-Gallon Compressor (68dB)

Note, the tanks also decrease the running time of the pump = longer life.

BTW if you do not believe me that pulsation from systems without air tanks happen, a company sells an in-line tank solution for that problem:

- Sparmax Air Tank System (2.5 Litres)

Basically, look for quiet (70DB or less), a tank, an auto shut-off, oil-less and portable helps.

If you have a tank: diaphragm, rotary and piston really do not matter that much but piston tends to be the more time-tested type.

|

A revolution is an idea which has found its bayonets.

Napoleon Bonaparte |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/11/30 17:04:09

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Just an FYI on the dB ratings, don't trust them. Some of them are absolute BS, I don't know if there's some standard on how you should measure the dB of compressors but I've heard some that were rated at a low dB but sounded horrible.

The compressor I've got isn't too bad, but most of the noise comes from vibration, if I pick it up by the handle while its running it goes quiet but sitting on the floor (even a soft carpet floor) it rattles like crazy and makes a lot more noise (not enough for me to care, but I wouldn't run it if someone was sleeping in the next room).

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/01 17:09:46

Subject: calling all airbrush aficionados

|

|

Ancient Venerable Black Templar Dreadnought

|

AllSeeingSkink wrote:Just an FYI on the dB ratings, don't trust them. Some of them are absolute BS, I don't know if there's some standard on how you should measure the dB of compressors but I've heard some that were rated at a low dB but sounded horrible.

The compressor I've got isn't too bad, but most of the noise comes from vibration, if I pick it up by the handle while its running it goes quiet but sitting on the floor (even a soft carpet floor) it rattles like crazy and makes a lot more noise (not enough for me to care, but I wouldn't run it if someone was sleeping in the next room).

Like with anything, the value is completely dependent on the method.

"I measure 60dB from the compressor when measured from 40 feet away in a padded room."

Yeah, if you hear a rattle, hunt down the loose bit and tighten it up.

Carpet underneath is ideal.

If it is near a wall, some cone shaped foam will help absorb and prevent noise reflection.

I find the dual cylinder pumps have smaller cylinders so don't "bang around" as violently to get the volume of air needed.

Again, having a decent compressor in the garage and a fillable tank may be the way to go.

There are a few options depending on your living conditions.

An apartment building and having a compressor banging away would not impress neighbors.

The near-silent pumps are based off of refrigerator rotary types and cost a fortune unless you can modify a fridge one:

http://www.instructables.com/id/How-to-modify-a-fridge-compressor-into-a-silent-ai/

There are many options to deal with design limits of the various compressors, I find the only real limit is your budget and how much work you want to do.

Good luck!

|

A revolution is an idea which has found its bayonets.

Napoleon Bonaparte |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/01 19:36:25

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Talizvar wrote: Talizvar wrote:Like with anything, the value is completely dependent on the method. "I measure 60dB from the compressor when measured from 40 feet away in a padded room."

Yeah that's why I wonder if there's some standard that they should be following or if they just invent their own testing method to get their BS numbers that can't really be compared from one compressor to the next  It's the same with computer fans, never trust the manufacturer's dB rating because there's no standard on how to measure them, you need a third party who has actually tested them consistently if you want to compare. I mention it because I've heard some low noise "rated" compressors that were nearly as loud as my shop compressor. When I used to work on a car racing team we had noise limits, but they were measured in a specific place and the car had to be at specific RPM when being tested, so we used resonators to get rid of noise at those RPM and shaped things to reduce noise in the area testers would be placed.... the car was waaaaay louder than it should have been but it passed the tests  Yeah, if you hear a rattle, hunt down the loose bit and tighten it up.

Oh believe me I've tried, I have no fething idea what's rattling, I'd have to pull apart the motor housing to track it down which I don't really want to do. In spite of the rattles it's lasted me a couple of years and many models have been sprayed

|

|

This message was edited 1 time. Last update was at 2016/12/01 19:38:07

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/01 21:02:15

Subject: calling all airbrush aficionados

|

|

Ancient Venerable Black Templar Dreadnought

|

AllSeeingSkink wrote:Oh believe me I've tried, I have no fething idea what's rattling, I'd have to pull apart the motor housing to track it down which I don't really want to do. In spite of the rattles it's lasted me a couple of years and many models have been sprayed

Covers are nothing to be afraid of.

They are to be considered "extra bits" that mask the glory of the actual working parts to be added to the cool bits box.

If you start digging into the cylinder head or something then it can get more "exciting" if you do not know what you are doing... especially if the tank is still pressurized or the compressor is still plugged in.

I like putting little notes for myself like "remember to vent", "are you sure?" and "NE TOUCHE PAS!!!"

My big beast of a pump is very quiet for what it is but I did add a few "features" around it to lower the noise so it would not disturb my painting zen.

It did seem to blend well with industrial and steampunk music however.

I figure I would build some stuff around the pump (minimal needed) rather than pay some 5X the cost for something quieter.

|

A revolution is an idea which has found its bayonets.

Napoleon Bonaparte |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/02 02:54:48

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Last time I pulled apart a cheap hobby compressor I broke a bunch of glued in parts that were a bitch to replace  I'll pull apart the cylinder heads on my car before I try that again  I dot think those cheap compressors are really designed to be serviced. One of the threads I broke (which had been epoxied in from the factory) was a weird size that I couldn't find replacements and had to retap it to a standard size, pain... in... the... arse.

It works, I don't really care that it rattles, but yeah, my original point was simply dont trust dB figures for anything unless there's an associated standard and certified measurement procedure.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/02 18:52:13

Subject: Re:calling all airbrush aficionados

|

|

Ancient Venerable Black Templar Dreadnought

|

Funny, looking up this topic I learned something neat to do with SCIENCE!

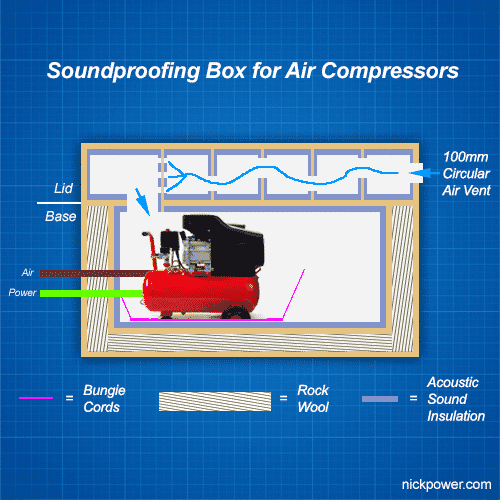

A guy made a sound cabinet for his compressor, looked big but neat.

https://www.artifacturestudios.com/archives/985/

But then how he was going to vent the cabinet was freaking bizarre.

Normal is to make some maze to gradually absorb the sound:

But instead this guy looked up something called a "sonic band gap structure".

The concept looks like this:

The squiggly lines are sound waves of varying low frequency stopped by the physical structure (They do something like this for microwave signal filtering as well).

Instead of using tubes like him I will use hockey pucks (the building material appeals to me)... now have to see the math on what frequency ranges I can stop with that.

Interesting the stuff you can come across.

Turns out my work has a fair bit of extra sound dampening foam/rubber/sheet I can use so the cabinet may get an upgrade.

|

A revolution is an idea which has found its bayonets.

Napoleon Bonaparte |

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/03 07:13:35

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

Yeah, if you've got time and space to burn you can build something like that. That picture probably needs an exhaust with an actual fan to provide cooling or else heat's going to be a problem and that in itself is another noise source. Putting blockage in the vent shaft reduces airflow efficiency which requires a more powerful fan that produces more noise  At work we have thick acoustic treated splitters that are designed to reduce noise with minimal airflow loss. For my compressor if I could suspend it with bungees that would eliminate most my noise. ...but I think we've strayed a bit from the OP's question. Which was something quiet that did what it needed to do out of the box... not something he has to build a room around to make it quiet

|

|

This message was edited 1 time. Last update was at 2016/12/03 07:16:41

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/03 13:30:57

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Pretty much, Skink! I'm gonna have another go at my existing one this afternoon with the 0.3 needle and see how I get on, even if it's just for getting the main colours down it'll help I guess.

Still science and gubbinz and stuff is always interesting and welcome

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/03 15:07:59

Subject: Re:calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Had another go, this time with the 0.3, and it's still sputtering like a flu ridden 30 a day smoker. Didn't thin my paint as much this time, and used a different paint to GW's.

When I "activate" the airbrush, the compressor changes pitch which I think is probably due to the lack of a regulator? Paint flow is varied, at first it came out nice and even, then I topped up with as close to the same paint:thinner ratio as I initially had, only for no paint to come out at all?

Is this just because if the compressor or is it me and lack of skill?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/06 07:40:56

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Any thoughts at all guys? I'm well out of my depth here and would prefer advice to making trial and error

Cheers

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/06 13:08:56

Subject: calling all airbrush aficionados

|

|

Focused Fire Warrior

|

It looks to me like the paint was too thick. If you have the .5 mm nozzle, I would step up to that. It is much less finicky on paint viscosity, and a great size to learn on. I learned on it for about a year before dropping down to .3. Frankly, I'm not sure that it matters much between the 2 sizes unless you are trying to airbrush in smaller details (which seems overly difficult for anyone with less than several years experience).

Also I cannot stress the importance of keeping your airbrush clean and lubricated. I use gun cleaner and machine oil to keep my airbrush nice and clean and well lubricated.

Also tamiya makes some small pointed cotton swabs that are absolute aces for keeping the brush clean.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/06 13:40:07

Subject: calling all airbrush aficionados

|

|

Grizzled Space Wolves Great Wolf

|

That splattering on the left side of the image? I'm not really sure. The paint does look on the thick side, but I don't normally see splattering like that with excessively thick paint.

Does it splatter constantly or is it just at the start or does it start spraying smoothly then slowly revert to splattering?

Is your airbrush good and clean and operating properly? Is the annulus the air flows through clear of any gunk? The nozzle clean and in good shape without any flaring or splits? Needle tip perfectly smooth without any dents, bends or kinks?

Without any paint or air, try drawing back the needle with the trigger and look carefully down the needle/nozzle and make sure everything is concentric, if the nozzle is offset you could be getting more air on one size than the other which could cause splattering.

|

|

This message was edited 1 time. Last update was at 2016/12/06 16:08:11

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/06 15:51:25

Subject: Re:calling all airbrush aficionados

|

|

Fresh-Faced New User

|

kitch102 wrote: kitch102 wrote:Is this just because if the compressor or is it me and lack of skill?

Not sure about the compressor, but give these two videos a watch if you haven't already:

https://www.youtube.com/watch?v=kUwlPztdYmo&index=86&list=PLRZfMTg3mTKG-VZQkhdOG7WnCOU2DeA1U&t=897s

https://www.youtube.com/watch?v=rLeWGzJbHzI&index=40&list=PLRZfMTg3mTKG-VZQkhdOG7WnCOU2DeA1U

The first will talk about the airbrush and compressor for a good bit, the second one will talk about actually using the brush. The compressor he recommended is what I ended up with, its about $100. I watched a good deal of Kenny's videos before I dropped on an airbrush, and his advice went a long way to getting me going with it pretty quickly.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2016/12/06 17:30:40

Subject: calling all airbrush aficionados

|

|

Secret Inquisitorial Eldar Xenexecutor

|

Thanks guys. All components are cleaned within minutes of use, with the nozzle front bits detached and soaked in brush cleaner, all other parts are hand washed under like warm water.

I also have some relatively softish airbrush cleaning brushes which I use to clean the accessible parts of the interior, before the airbrush is left leave to air dry indoors.

|

|

|

|

|

|

|

|