| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 12:28:53

Subject: Help - Smoothon 66D bubbles in resin.

|

|

Grumpy Longbeard

|

Hello guys.

Question:

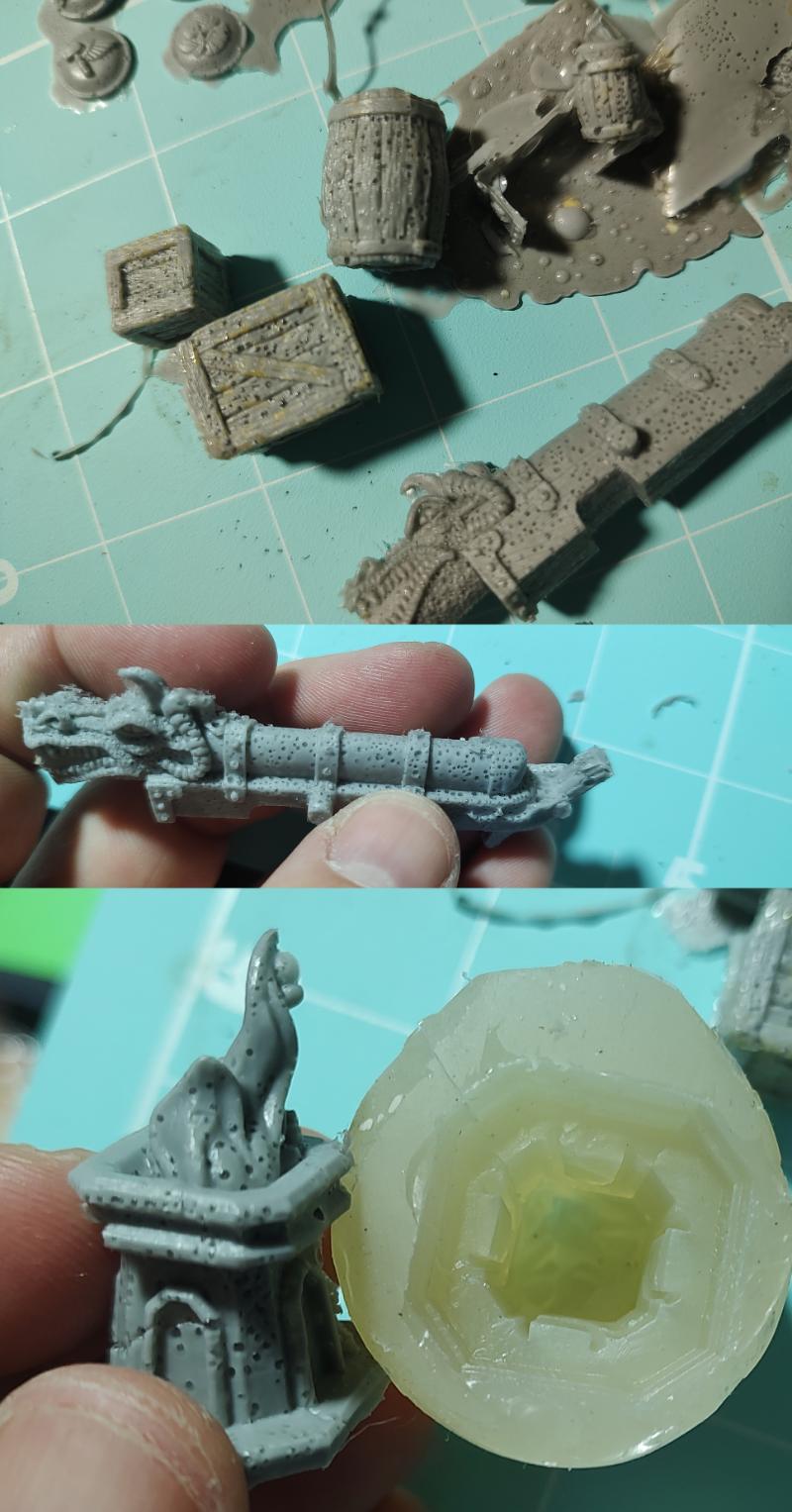

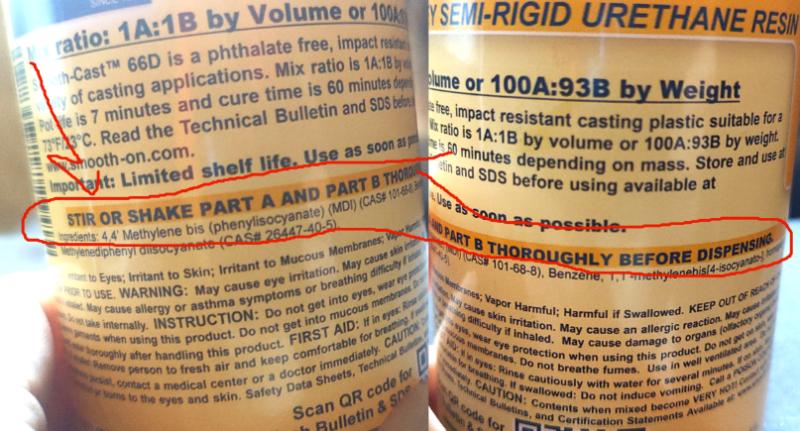

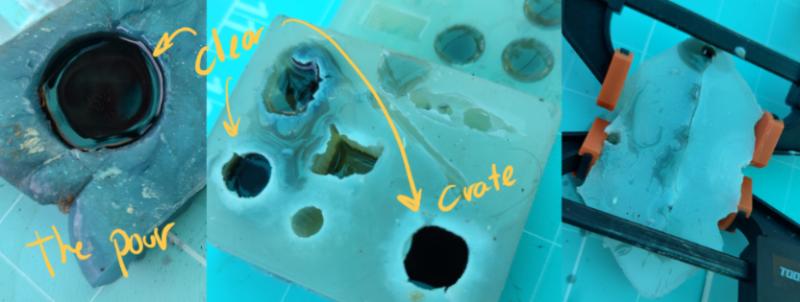

Ordered new Smoothon 66D

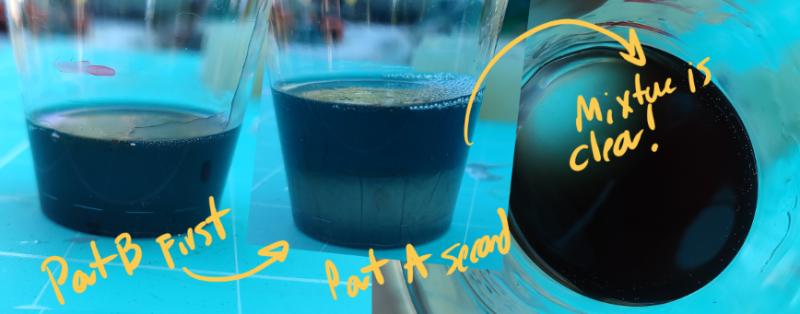

Using plastic stir-stick and cup, mixing slowly for a minute, shook the bottles prior to mixing as instructed, then tried without shaking the bottles, pouring in-door to minimize moisture.

The mixture is clean, but as the resin cures tiny bubbles form up and the cast ends up being like a aero-chocolate bar. I do not own a pressure pot.

What am I doing wrong?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 14:58:43

Subject: Help - Smoothon 66D bubbles in resin.

|

|

Utilizing Careful Highlighting

|

When I resin cast, I usually have to burp the molds (ie, lightly tap the bottom of the mold against a flat surface as I pour in the resin) so that the air bubbles work their way to the surface. But I've never seen bubbles quite like what you're getting.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 18:16:39

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Quick-fingered Warlord Moderatus

|

I think you need to subject the resin to a vaccum to draw out the gasses which give you those bubbles.

You may have to swallow pride and check out some 'how to' videos on le interweb

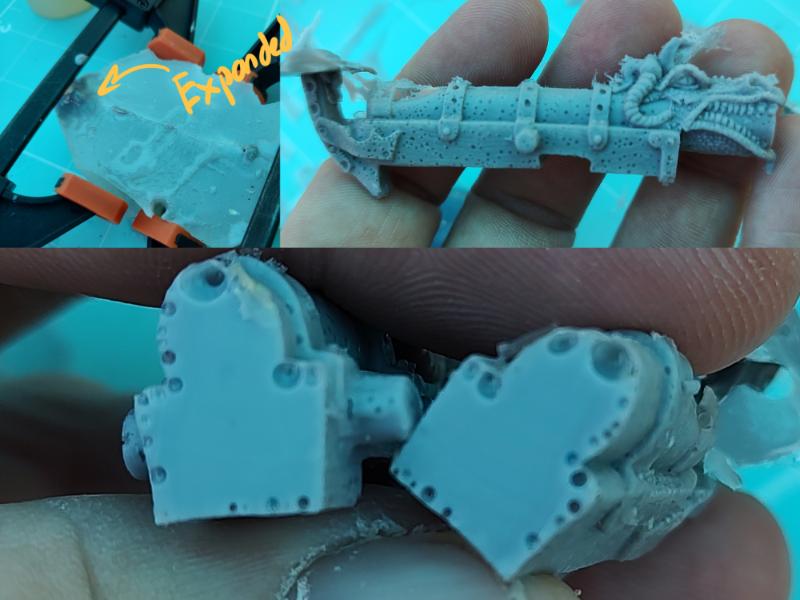

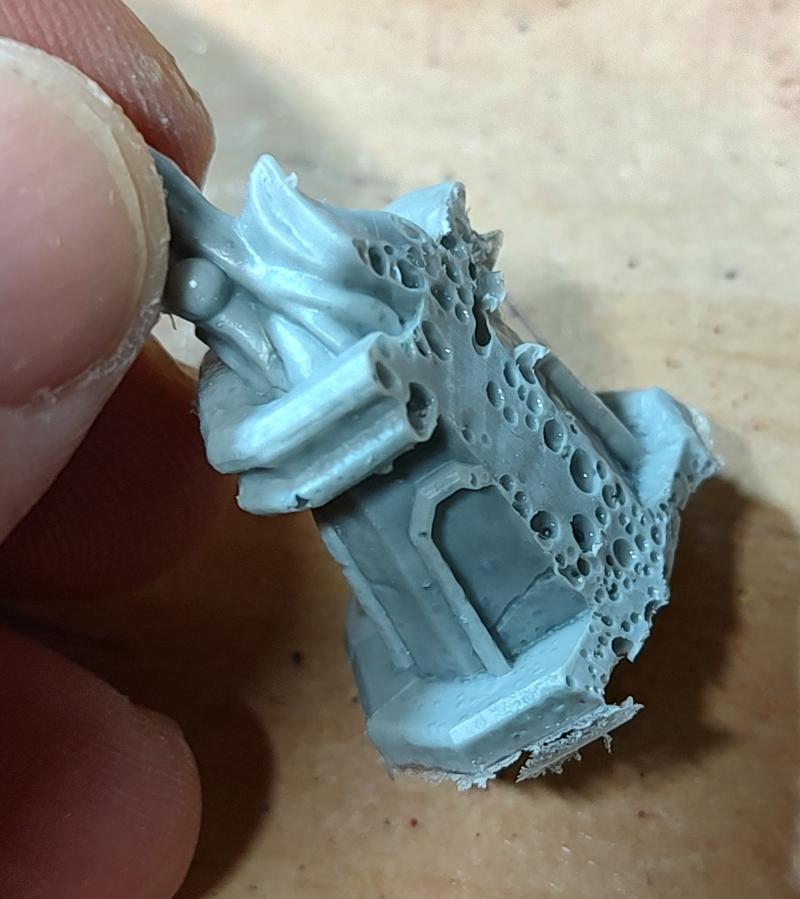

Also, the effect you got on the cannon bit does look cool af - possibly nurgle infestation?

|

https://www.youtube.com/channel/UC-px27tzAtVwZpZ4ljopV2w "ashtrays and teacups do not count as cover"

"jack of all trades, master of none; certainly better than a master of one"

The Ordo Reductor - the guy's who make wonderful things like the Landraider Achillies, but can't use them in battle..  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 19:45:29

Subject: Help - Smoothon 66D bubbles in resin.

|

|

Shadowy Grot Kommittee Memba

The Great State of New Jersey

|

You either need a vacuum chamber or a shaker to shake out the bubbles fully.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 21:58:24

Subject: Help - Smoothon 66D bubbles in resin.

|

|

[MOD]

Making Stuff

|

KidCthulhu wrote: KidCthulhu wrote:When I resin cast, I usually have to burp the molds (ie, lightly tap the bottom of the mold against a flat surface as I pour in the resin) so that the air bubbles work their way to the surface. But I've never seen bubbles quite like what you're getting.

This. If you don't have a vaccuum chamber, you need to get the bubbles out some other way. Tapping the mould as you pour and for a minute or two afterwards can help. I've had some success in the past by applying a handheld massager to the benchtop the moulds are sitting on.

With some resins it can also help to paint a layer of resin onto the walls of the mould with a paintbrush before pouring the rest, to minimise the bubbles caught against the mould during the pour.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/24 23:27:22

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Grumpy Longbeard

|

Thank you guys for help.

Unfortunately here are the conditions:

1 - Before pour, I scoop small amount and coat every detail, pushing in the tool to get the resin into undercuts and details. (Will try with a brush)

2 - Then I pour the resin in, the resin is clear with no bubbles. (I do not think a vacuum-pot would help because the mixture is pretty clear)

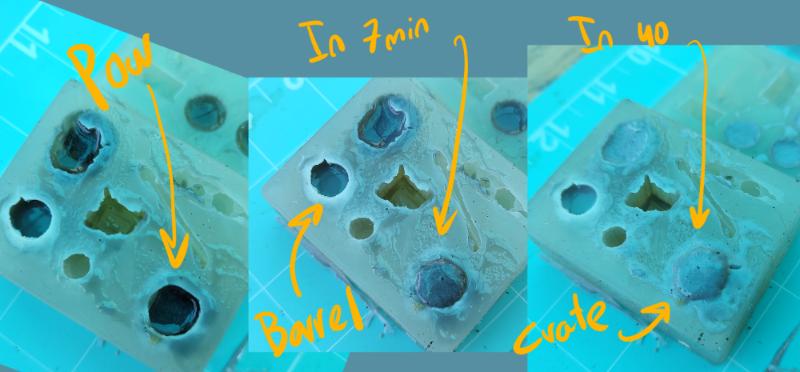

3 - As it cures it becomes opaque, micro bubbles form then grow larger, and the pour rises like bread in oven, sometimes doubles in volume.

4 - Massage tool is a good idea, I'll give it a try, however it probably wont help because 66D - Work time is 5 min sets in 7 min, cure time is 15-18 min. But I will try.

5 - Pressure pot is good, as the gas shrink under pressure, and any bubbles become too small to make a difference. But I am NOT buying a pressure pot, just to cast 4 wheels and a cannon. If I have to spend money, I'll just buy 2 extra kits instead of a pressure pot.

ChatGpt information listed (moisture/humidity) as one of possible factors, but I was heat gunning silicone mold before pouring to no avail. Also, outside is pretty hot and dry.

Of course I would (pressure pot) if I had it.

Of course I can throw away 66D and buy Smoothon 300D that has longer cure time that will allow for the bubbles to rise up to the surface.

Was hoping someone ran into same exact issue and found an exact solution, so I could avoid spending more money.

some fails - https://www.dakkadakka.com/dakkaforum/posts/list/150/780044.page#11773127

Will share progress

Automatically Appended Next Post:

SirDonlad wrote: SirDonlad wrote:I think you need to subject the resin to a vaccum to draw out the gasses which give you those bubbles.

You may have to swallow pride and check out some 'how to' videos on le interweb

Also, the effect you got on the cannon bit does look cool af - possibly nurgle infestation?

I've already searched the web, asked ChatGPT, checked YouTube, and even emailed Smooth-On support with this question—nothing came close to addressing what I'm experiencing. So now I turn to Dakka, my last refuge of experts.

Usually yes, but this is a dwarf cannon, and Nurgle has no power over the Dawi.

|

|

This message was edited 2 times. Last update was at 2025/08/24 23:40:59

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 01:36:49

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

[MOD]

Making Stuff

|

Mothsniper wrote: Mothsniper wrote:3 - As it cures it becomes opaque, micro bubbles form then grow larger, and the pour rises like bread in oven, sometimes doubles in volume.

This sounds like maybe the shaking/mixing is leaving microbubbles in the mix that aren't visible, that are then expanding from the heat as the resin cures. More gentle mixing instead of shaking before the pour may help.

From stuff I've read, gently warming the resing and/or applying heat as the resin cures can help, although with a fast-cure resin that can be problematic.

Spritzing the top of the resin with Isopropyl alcohol to break the surface tension, and combining that with some vibration may be the way to go.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 17:21:31

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Grumpy Longbeard

|

insaniak wrote: insaniak wrote: Mothsniper wrote: Mothsniper wrote:3 - As it cures it becomes opaque, micro bubbles form then grow larger, and the pour rises like bread in oven, sometimes doubles in volume.

This sounds like maybe the shaking/mixing is leaving microbubbles in the mix that aren't visible, that are then expanding from the heat as the resin cures. More gentle mixing instead of shaking before the pour may help.

From stuff I've read, gently warming the resing and/or applying heat as the resin cures can help, although with a fast-cure resin that can be problematic.

Spritzing the top of the resin with Isopropyl alcohol to break the surface tension, and combining that with some vibration may be the way to go.

Automatically Appended Next Post:

Automatically Appended Next Post:

Got the reply from the Smoothon guys. Will be testing today.

|

|

This message was edited 2 times. Last update was at 2025/08/25 19:26:29

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 17:56:36

Subject: Help - Smoothon 66D bubbles in resin.

|

|

Utilizing Careful Highlighting

|

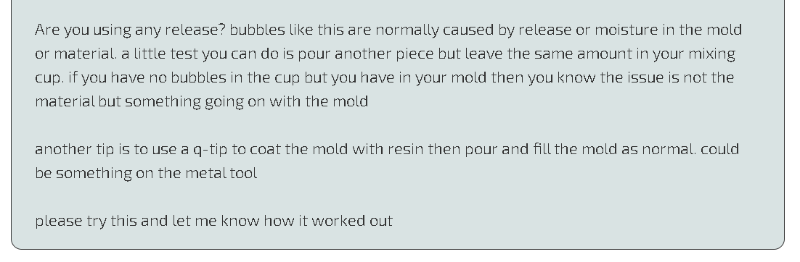

Huh, I didn't even think about the mold release. I often use baby powder in my molds when I run out of commercial mold release.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 19:19:00

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Grumpy Longbeard

|

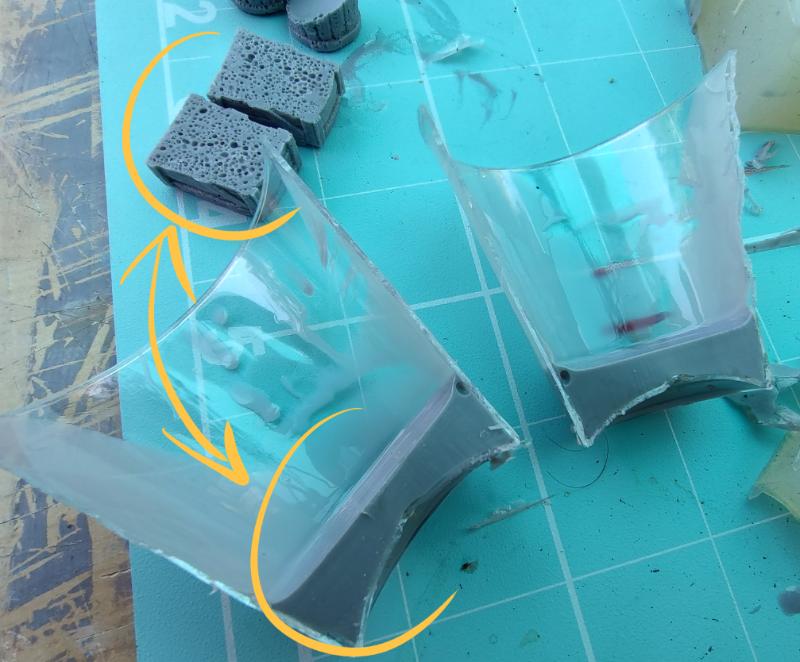

Hope you guys can see that common bubble removal is not the issue here.

Something in the mold is reacting with this resin.

Notice the expansion

The bubbles form and grow as the resin cures, I can't "shake" them to the surface

Same pour same mold, two reactions.

Resin left in cup cured normally without bubbles forming.

Interestingly enough, the wheel cameout ok-ish

|

|

This message was edited 2 times. Last update was at 2025/08/25 19:20:11

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 20:33:26

Subject: Help - Smoothon 66D bubbles in resin.

|

|

[MOD]

Making Stuff

|

Yeah, that does look pretty conclusive. I'd try giving the moulds a good scrub in warm soapy water and then a thorough dry, and if it's still happening it might just be time for new moulds in a different silicon.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 20:57:50

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Quick-fingered Warlord Moderatus

|

This is actually fascinating.

The mold seems to be catalyzing the resin

What material is the mold?

|

https://www.youtube.com/channel/UC-px27tzAtVwZpZ4ljopV2w "ashtrays and teacups do not count as cover"

"jack of all trades, master of none; certainly better than a master of one"

The Ordo Reductor - the guy's who make wonderful things like the Landraider Achillies, but can't use them in battle..  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2025/08/25 21:24:22

Subject: Re:Help - Smoothon 66D bubbles in resin.

|

|

Grumpy Longbeard

|

It was a silicone mold from tap The one I had is old like from 2017-ish

Smoothon support did mention that talk or cornstarch would provide enough of the barrier. So, I will try with cornstarch first.

If no improvement, then I'll wash in iso then soap then air dry for a couple of days, then hair-dryer before the pour and try last time before I give up.

Thanks guys. Automatically Appended Next Post: More fail lolz

The heat destroyed the thermoplastic mold.

But GOOD NEWS!

Cornstarch did help with the surface!

|

|

This message was edited 2 times. Last update was at 2025/08/25 22:57:34

|

|

|

|

|

|

|