| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 16:07:13

Subject: dealing with slippery table surfaces

|

|

Morphing Obliterator

|

morning dakka,

I had a game last night where the table was covered in the plastic realm of battle plates from GW, painted up as snow/ice. while they looked great, they were super slippery and we had a hard time getting models to stay put on any of the sloped areas. for a couple fights, we actually had to resort to double-sided tape to keep the models in place! this got me thinking about applying some sort of rubber-like coating to the bottom of my bases. my first thought was rubber cement, but I'm not sure how evenly I'd be able to apply it or if it would even give me enough friction. anyone other ideas?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 16:11:25

Subject: dealing with slippery table surfaces

|

|

Bloodthirsty Chaos Knight

|

What about that rubber stuff that is used to coat handles of wrenches and stuff? That might work.

|

“Yesss! Just as planned!”

–Spoken by Xi’aquan, Lord of Change, in its death throes |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 18:04:52

Subject: dealing with slippery table surfaces

|

|

Morphing Obliterator

|

sounds promising. any idea what it's called or where I'd find it?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 18:07:59

Subject: dealing with slippery table surfaces

|

|

Bloodthirsty Chaos Knight

|

|

“Yesss! Just as planned!”

–Spoken by Xi’aquan, Lord of Change, in its death throes |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 18:22:19

Subject: dealing with slippery table surfaces

|

|

Morphing Obliterator

|

perfect! wonder if my local hardware store has anything similar... thanks for this

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/12 18:25:27

Subject: dealing with slippery table surfaces

|

|

Bloodthirsty Chaos Knight

|

I'd sure they do, if not by a different name. Comes in different colors too. You could dip just the lip of the bases in different colors for different squads, for example. Let us know how it works out.

|

“Yesss! Just as planned!”

–Spoken by Xi’aquan, Lord of Change, in its death throes |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 00:21:12

Subject: dealing with slippery table surfaces

|

|

Longtime Dakkanaut

|

Either that, or rubberized undercoating spray. Would probably be easier for any bases that haven't yet been attached to miniatures yet, but let us know how the liquid rubber works.

|

Why is it that only those who have never fought in a battle are so eager to be in one? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 02:41:42

Subject: Re:dealing with slippery table surfaces

|

|

Nasty Nob

|

The dip looks cool, but I'm not sure how non-slip it will end up being.

Two different things that I have done (both of which work). For models with movement trays, I put a sheet of craft felt (backed with adhesive) on the bottom of the tray. Not only does this prevent a lot of skidding, it also prevents the bases from scraping up a painted board. This might not work for individual round bases, since they are hollow.

I have also used Play-dough craft foam on individual bases. I put a bit of glue in the base, then pressed some of the foam up into the glue. Then just smoothed the foam off level with the bottom of the base. This gives the base more surface contact with the board, plus the foam isn't slippery like plastic. It's also cheap as heck.

If you try the rubberizing dip, let us know how it works!

|

|

This message was edited 1 time. Last update was at 2013/02/13 02:41:53

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 15:48:39

Subject: Re:dealing with slippery table surfaces

|

|

Morphing Obliterator

|

I hit up the hardware store last night and they happened to have the exact product that nectarprime linked earlier. pretty easy to use: peal off the metal seal, dip the rim of the base into the goo for a few seconds and then slowly lift it out. the instructions say to let it hang dry, but that's a bit tricky for minis because you can't get the base level. this means you might end up with more goop on one part of the base then on the rest. for my test model, I let it hang dry for a couple minutes and then turned it upside down so the base was facing up and fairly level, then braced it like that to dry overnight (instructions say drying time is about 4 hours). the goo in the can does smell fairly awful, though, and the provided plastic lid does *not* seal. I put a few layers of plastic wrap under the lid and I can still smell it if I hold the can up to my nose, so I think I'll have to put the can in a ziplock bag or something. the whole can will solidify if exposed to air over time, so you need an airtight seal between uses. on the plus side, after drying overnight I can't smell the goo in the mini itself.

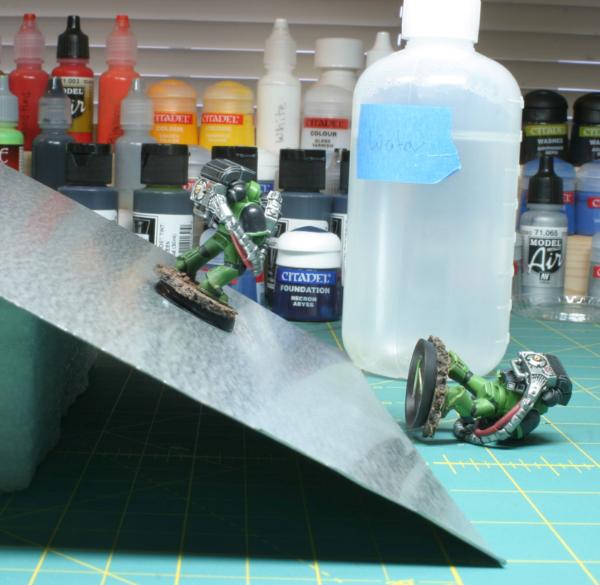

anyway, here's the result:

this is a sheet of metal that's fairly slippery, angled at about 30 degrees. I couldn't raise it any further than that because the mini is top heavy and it would tip over. I think if I weighted the base down with a penny or washer, I could raise the angle even more without the mini sliding down. the coating on the rim isn't as even as it could be, but the mini doesn't wobble when it's on a flat surface. the coating is also shiny, but I'm sure that could be fixed with some matte varnish. the face-planted mini has no coating on the base and started sliding at around 15-20 degrees.

for models that are already based, this seems like a reasonable solution. my hardware store also had a spray-on rubber undercoat made by the same company. as fenrir1997 pointed out, I think that could be a better option for unattached bases because you don't have to deal with hanging things to dry, etc. and you also don't have to worry about the can of goo solidifying on you between uses. I'm just not sure if the spray-on coating would be thick enough to do the job.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 17:15:27

Subject: dealing with slippery table surfaces

|

|

The Hive Mind

|

Would filling them with hot glue not give enough friction?

|

My beautiful wife wrote:Trucks = Carnifex snack, Tanks = meals.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 17:43:48

Subject: dealing with slippery table surfaces

|

|

Morphing Obliterator

|

rigeld2 wrote:Would filling them with hot glue not give enough friction?

I haven't used a hot glue gun before, so I don't know how smooth/hard it is when dry. would probably work if the glue doesn't dry too hard. you'd have to figure out how to make sure you end up with a level surface, though. is the glue fluid enough to self-level when it's hot?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 21:34:48

Subject: dealing with slippery table surfaces

|

|

The Hive Mind

|

Not really but it's trivial enough to flatten it out before it fully hardens.

Glue sticks might be cheaper than your solution is the only reason I bring it up. Also dries faster and no funky fumes.

|

My beautiful wife wrote:Trucks = Carnifex snack, Tanks = meals.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/13 22:14:11

Subject: dealing with slippery table surfaces

|

|

Morphing Obliterator

|

rigeld2 wrote:Not really but it's trivial enough to flatten it out before it fully hardens.

Glue sticks might be cheaper than your solution is the only reason I bring it up. Also dries faster and no funky fumes.

yeah, it's definitely worth considering because the can of goo is about $12. spread out over the dozens of bases it could coat, the cost is trivial, but if the can dries out before you can use most of it, then it's not very cost effective. that's my only concern with the can at this point; fumes are no biggie for me because I keep a heavy duty mask around for airbrushing and my hobby area has a window.

I think I'm going to give the spray-on stuff a try as well, just to compare. would be a lot more convenient for new bases than trying to dip them. could probably even use it for already-based minis if I can come up with an easy way to avoid overspray... hmm, which gives me an idea. to the hardware store! :p

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/14 00:17:00

Subject: dealing with slippery table surfaces

|

|

Longtime Dakkanaut

|

A good way to avoid the overspray would be to get the widest masking tape you can get your hands on (2-3 inches?) and just wrap up your mini. At least that's what I would do..OR you make some interesting cuts out of a sheet of cardboard so that the mini goes through a hole, but not the base. Mask the hole on the mini side just in case of some overspray through the hole, and you're rockin'

And as for "Hang dry," I would just dip the mini's base, then set it on wax paper. Ensures the goo will set level, and the mini isn't heavy enough to squish it out from the lowest parts. When set, peel it off and go  At least that's how it works in my head, with my luck I'd probably have wax paper stuck to the base....

What I typically do as of now for that kind of thing, is play with alligator clips. I've got a small board with holes drilled in it for the clips to set, and clip them ahold of the mini, set, and forget

I'm a fan of the hardware store for crap like this. I think I'll be grabbing a can-o-dip myself.

|

Why is it that only those who have never fought in a battle are so eager to be in one? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/14 00:29:43

Subject: Re:dealing with slippery table surfaces

|

|

Morphing Obliterator

|

the 2 part cardboard mask is exactly what I was thinking of trying out. the wax paper is an interesting idea, however, so I'll try that out first since I already have the can of goo. will post my results when I get a chance to try it.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/14 00:35:11

Subject: dealing with slippery table surfaces

|

|

Longtime Dakkanaut

|

Great minds think alike

Looking forward to the results!

|

Why is it that only those who have never fought in a battle are so eager to be in one? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/14 05:02:33

Subject: Re:dealing with slippery table surfaces

|

|

Morphing Obliterator

|

mixed results with the dip and dry on waxed paper method.

on the plus side:

- it's fast

- you get an even (though very thin; see minuses) coating along the bottom edge of the base

- it doesn't stick to the waxed paper

on the minus side:

- the weight of the mini is enough to press most of the goo out from underneath the bottom of the base, even after letting the goo dry for a couple minutes before setting it down on the waxed paper. this makes it so you only get a very fine layer of goo on the bottom edge of the base. this is with a plastic mini, mind you, so a metal one would probably squeeze out even more of the goo.

- you end up with rubberized flash around the bottom edge of the base. it's tricky to trim off without accidentally pealing the coating away from the base.

- this won't be an issue for a while, but once you work your way through about 1/3 of the can, it's going to be tough to get your hand in there to dip the bases (also pretty tough to see what you're doing so you don't overdip, too).

having said all this, when I gave it the same slip test I did earlier, friction seemed to be about the same (I used the other devastator mini, so weight/balance was the same). the thinner layer has a similar hold, though I imagine it will wear off faster.

for the sake of science, I think I'll pick up a can of the spray-on stuff this weekend and give that a go as well.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/16 08:10:00

Subject: Re:dealing with slippery table surfaces

|

|

Morphing Obliterator

|

I picked up a can of the spray-on stuff tonight; it's made by the same company that makes the can of dip I tested out earlier (plasti-dip).

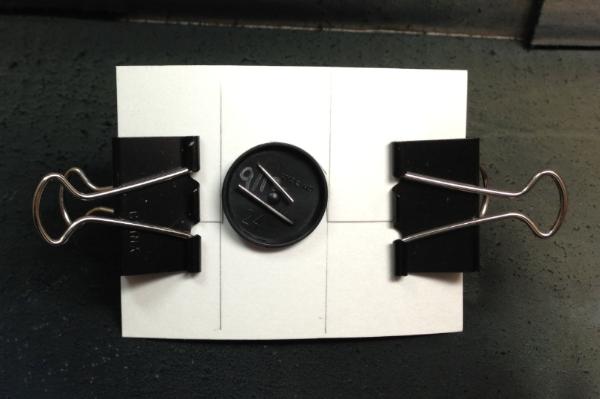

to prevent over spray, I probably could have just wrapped the entire mini in my hand, but I decided to make a simple mask just to test the idea. I used two pieces of poster board and cut a base-sized semi circle out of one edge on each piece. I cut the circles slightly deeper than 12.5mm so that I could overlap the two pieces and have a perfect, base-sized hole in the center. that way I don't have to worry about sealing where the two pieces of board meet in the middle. here's what it looks like with a mini ready for spraying:

the spray-on stuff goes down nice and easy, but it does make a bit of a mess and smells WAY worse than the dip. you definitely want to do this in a well ventilated area and on a surface you don't care about (I sprayed into a cardboard box). one coat seems to be plenty and leaves an even layer without any drips or bubbles. it seems to provide slightly better friction than the dip, probably because the coating is more even.

spray-on is the way to go:

- more convenient application

- better, more even coating

- the spray-on can doesn't leak nasty vapors like the dip can does

- the spray-on can is about $3 cheaper than the dip can (admittedly for much less product)

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2013/02/16 08:39:01

Subject: dealing with slippery table surfaces

|

|

[MOD]

Anti-piracy Officer

Somewhere in south-central England.

|

I suggest before you spray the anti-slip material you fill the base with lead shot and plastic padding (polystyrene resin).

This will give you a weighty base against tipping and means you need less anti-slip material.

I am sure there is no difficulty buying bulk lead shot in the USA.

|

|

|

|

|

|

|

|