| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 08:04:40

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Battleship Captain

|

So orky... so cool. Well done.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 11:42:40

Subject: Re:Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Thank you gentle peeps,

So now I am playing about trying to make some odds and sods before settling down onto next project.

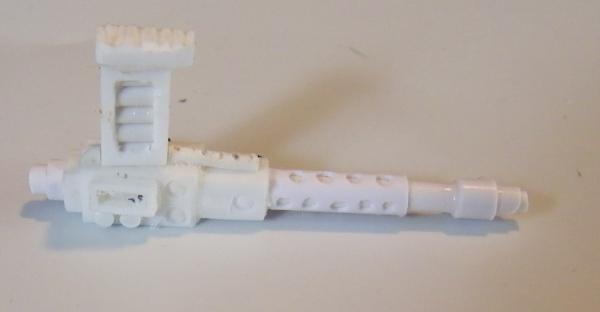

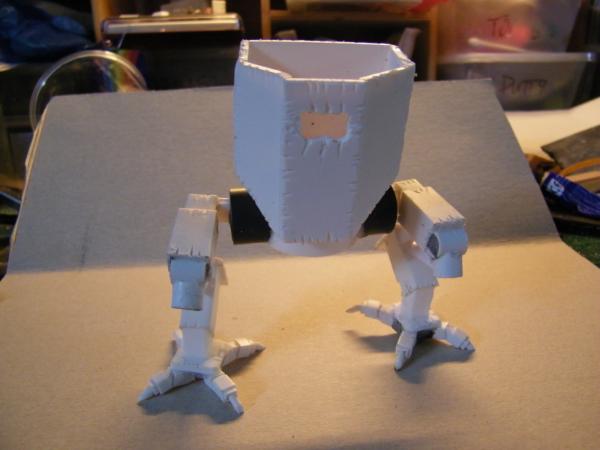

Here is a big shoota.

Might make a couple more and experiment with me casting.

Talking of which.....

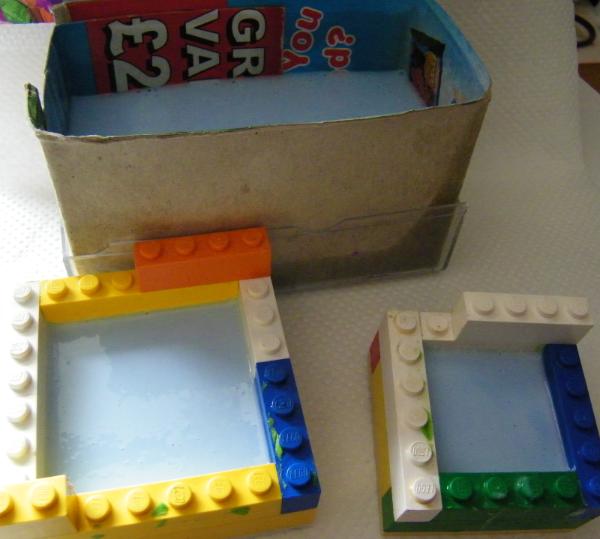

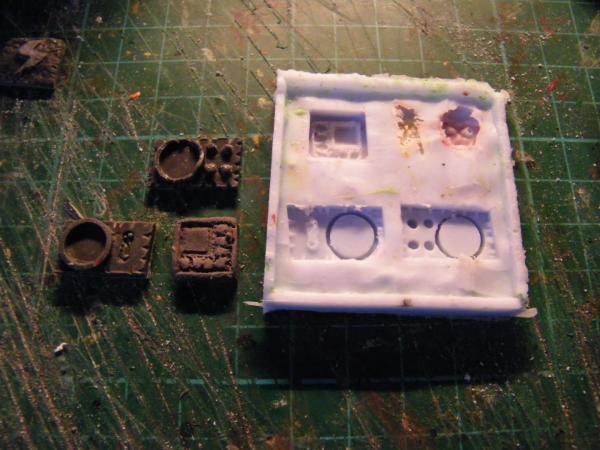

Moulds in the making here........

You will have to wait for later to find out if I am a complete numpty.

Cheers for now, update you later.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 12:09:51

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Shroomin Brain Boy

|

Be sure of my crossed fingers mate!

That big shoota looks amazing (taking notes furiously)

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 12:12:35

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Near Golden Daemon Caliber

|

Yeah, that's a fancy gun for sure. Intrigued by the molds, i may have to try it myself sometime, if only i come up with something worth casting

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 14:31:36

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Mastering Non-Metallic Metal

|

Good job on the shoota.

Good luck with the moulds. What's the cure time of your silicone?

|

Mastodon: @DrH@dice.camp Mastodon: @DrH@dice.camp

The army-                            ~2295 points (built). ~2295 points (built).

* -=]_,=-eague Spruemeister General. * A (sprue) Hut tutorial *

Dsteingass - Dr. H..You are a role model for Internet Morality!  // inmygravenimage - Dr H is a model to us all // inmygravenimage - Dr H is a model to us all

Theophony - Sprue for the spruemeister, plastic for his plastic throne! // Shasolenzabi - Toilets, more complex than folks take time to think about!  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 14:44:16

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Well the mix I am using says 2 hours, but taking longer, guess temp is affecting it a bit. Did one lot last night and left over night, was very happy, this is the second half if you like, and taking a while. Watched kettle never boils!!

It says to prolong the life of the mould not to use poly resin for 5-7 days, but there is no way I am waiting that long this time around. Should have something to show tonight.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 14:58:46

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Mastering Non-Metallic Metal

|

Oo, 2 hours is a quick one.

Yes, temperature does affect the reaction (like all reactions). But it's not a huge change, mine says at 60deg it'll take half the time that is does at 24deg.

You've jumped right in to 2 part moulds, like I did. Good man.

Look forward to seeing what it is, that it is, that you are teasing us with.

|

Mastodon: @DrH@dice.camp Mastodon: @DrH@dice.camp

The army-                            ~2295 points (built). ~2295 points (built).

* -=]_,=-eague Spruemeister General. * A (sprue) Hut tutorial *

Dsteingass - Dr. H..You are a role model for Internet Morality!  // inmygravenimage - Dr H is a model to us all // inmygravenimage - Dr H is a model to us all

Theophony - Sprue for the spruemeister, plastic for his plastic throne! // Shasolenzabi - Toilets, more complex than folks take time to think about!  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 17:19:20

Subject: Re:Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Ok. Here we go.

So it took closer to 4-5 hours to cure. But I left it in a draft, so maybe it was a bit cool. Stuck it under me lamp for a bit and hey presto.

So what follows is a load of pictures. For this batch here I have used 200g of silicon for the moulds. This was excessive, but easier to calculate out. And then made up 100g of resin. Again far too much for the job, but that is something I can work on, and I am not after a profit here so it is no biggy. Using olive oil to help as a demoulder.

The moulds coming out.

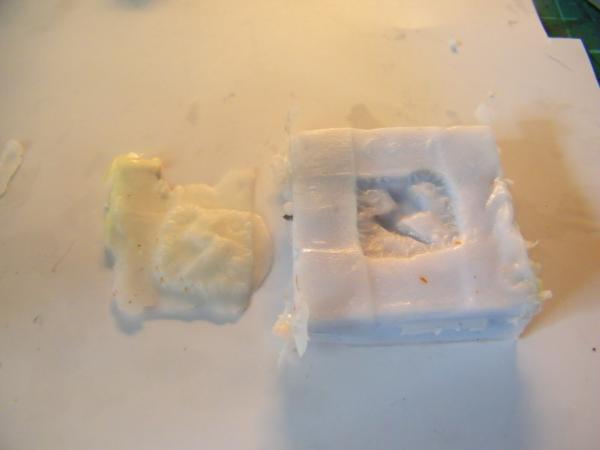

Bit of cobbled flooring. Just used plastacine to rough out, poured the silicon over and hey presto. Also you can see the ork icon mould, same thing, just sculpted up a bit of plastacine.

The Biggy. Ork track unit. Made it ambidextrous. ie, can be used mono, or on either side of a vehicle.

Made up a track unit in PC, laid it half buried in plastacine. Poured one half, then inverted and poured other half.

And so patience being my most lost forever of virtues....stuck resin in it didn't I......................

Now that only takes like about 20-30 minutes to be done so......

Most of this is old bits I have done up for use as scenery props. Just playing around trying to get a feel.

Then comes the track unit.

I did have a tiny problem with the unit, 2 air bubbles on the very top of it, might have to think on that one, however, already made them into battle damage. (it is orks after all.)

As I was using the resin I thought I had a lot left, so in a blind panic threw some plastacine around a rock, covered it in olive oil. poured some resin in and

So group shot....

I will post a painted pic of the track unit soon, primer drying as I type.

For my first ever attempt I am very pleased and, barring the smell, everything was easy and straight forward, a bit ogf thought and a bit more accuracy in the amounts and I should be spot on. As I said it is really only for me, so happy enough.

Thoughts?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 18:48:41

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Rogue Inquisitor with Xenos Bodyguards

|

Making your stuff now!

|

"Your mumblings are awakening the sleeping Dragon, be wary when meddling the affairs of Dragons, for thou art tasty and go good with either ketchup or chocolate. "

Dragons fear nothing, if it acts up, we breath magic fire that turns them into marshmallow peeps. We leaguers only cry rivets!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 20:17:35

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Mastering Non-Metallic Metal

|

Good job, Cam.

A few things I can spot;

Could probably do with more registration keys in your 2-part moulds. Can never have too many appears to be the thing.

You may be using too much mould-release agent (olive oil). Difficult to tell from the photos, but thought I'd mention it. You only need a thin coat. Otherwise you can loose fine detail in the casts when the oil fills the holes in the mould.

And silicone moulds can be modified to prevent bubbles that show up. Find where the air is trapped and cut a groove into the silicone to release it (only needs to be a thin channel). They can go to the edge of the mould or the "out" channel, but don't join them to the "in" channel.

You can also place the mould at an angle to force the air to certain areas and out your newly cut release channels.

Also, for the resin into silicone, try using talc (unscented) instead of oil. It's supposed to act as a flow aid and prevents bubbles sticking to the surface as well as a release agent. Oil would be more likely to trap bubbles.

Hope that helps.

|

Mastodon: @DrH@dice.camp Mastodon: @DrH@dice.camp

The army-                            ~2295 points (built). ~2295 points (built).

* -=]_,=-eague Spruemeister General. * A (sprue) Hut tutorial *

Dsteingass - Dr. H..You are a role model for Internet Morality!  // inmygravenimage - Dr H is a model to us all // inmygravenimage - Dr H is a model to us all

Theophony - Sprue for the spruemeister, plastic for his plastic throne! // Shasolenzabi - Toilets, more complex than folks take time to think about!  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 20:44:39

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

All taken on board, thank you. The "too much" oil bit in particular. It is not bad, but definitely lost some of the detail. And that explains it.

I know the track area looks a bit scruffy, but had to fill the gaps, could not have the mould running through, not sure if this is the right thing to do or not, did think of separate tracks, maybe on the next one.

Guns will be next, and feeling an itch for something nasty.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 20:46:13

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Shroomin Brain Boy

|

....cam... you truly are a man of so many talents...

that first batch is a very promising outcome! also with that track unit for me you have tackled the pinnacle of casting projects even in the first try.... you have balls xxxl size it seems! boldness but cunning and lucky too! you said the smell was off... how or what like did it smell? is it something you should only try in the cellar?...(I am asking this as I do my hobby stuff in our living room...  )

I am very eager now to see primed and maybe washed at least casted objects....I bet you are all jiggly all over due to this immense success  bravo!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 21:34:33

Subject: Re:Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Thank you Vik,

Primed?

Very happy with cobbles. I can trim them to fit bases if required, could also probably stick a bunch together for larger areas...

Oh and this.............

And next.....

Thanks for stopping by.....please feel free to comment. Automatically Appended Next Post: Oh and Vik the smell.......I am in living room also, and wife complained a bit, but windows open and a fan going and it was soon gone. Bit chemically on the resin, silicon was fine, no noticable smell at all.

|

|

This message was edited 1 time. Last update was at 2014/07/03 21:36:30

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 21:42:24

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Mastering Non-Metallic Metal

|

Painted up nicely, Cam.

What was it that you used as a mould for the barrel and wheel, looks like a putty rather than a poured silicone?

|

Mastodon: @DrH@dice.camp Mastodon: @DrH@dice.camp

The army-                            ~2295 points (built). ~2295 points (built).

* -=]_,=-eague Spruemeister General. * A (sprue) Hut tutorial *

Dsteingass - Dr. H..You are a role model for Internet Morality!  // inmygravenimage - Dr H is a model to us all // inmygravenimage - Dr H is a model to us all

Theophony - Sprue for the spruemeister, plastic for his plastic throne! // Shasolenzabi - Toilets, more complex than folks take time to think about!  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 21:49:19

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Yup it was a putty I got ages ago. It was called blue stuff. Absolutely brilliant, however these are probably the last I will get out of them as they are "crystalizing". ie the silicone is becoming brittle and cracking. Up to now I only used green stuff pressed into them and it worked pretty good. but they are stiffening up now. If it was not for your melty putty stuff, I would recommend it for some of your work.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 21:57:06

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Mastering Non-Metallic Metal

|

Yeah, heard of blue stuff.

How old is it to be going off like that?

Melty putty stuff (or Oyumaru) for the win.

Love that stuff.

|

Mastodon: @DrH@dice.camp Mastodon: @DrH@dice.camp

The army-                            ~2295 points (built). ~2295 points (built).

* -=]_,=-eague Spruemeister General. * A (sprue) Hut tutorial *

Dsteingass - Dr. H..You are a role model for Internet Morality!  // inmygravenimage - Dr H is a model to us all // inmygravenimage - Dr H is a model to us all

Theophony - Sprue for the spruemeister, plastic for his plastic throne! // Shasolenzabi - Toilets, more complex than folks take time to think about!  |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 22:00:10

Subject: Re:Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Member of a Lodge? I Can't Say

|

Hey mate!

Hope your well....

WWOW... i have missed a lot here! Going to go back through it in some detail but looking really awesome!

That landing pad is inspired.....VERY orky but can still be easily recognised...

Surfing Ork..... well.. theres not much more to say about that!!

And casting aswell.... good stuff mate! You will have to share your recipies ( maybe you have in the blog... i will read and see)

Awesome stuff..... if i wasnt allready in a position of having about 4 unfinished projects... this blog would seriously make me concider an Orky addition!

Cheers mate!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 22:08:36

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Combat Jumping Ragik

|

Wow, ambitious. Very cool. And very good for a first time. Impressive.

A note on the release agent. I have heard that a small amount of liquid dish soap can make a great release agent for pewter casting. I have no idea about resin, but it is something to consider. It would certainly make clean up easier.

I'm wondering about the lack of really sharp edges on the castings. Is that due to the masters being that way or the nature of the resin?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/03 22:16:36

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Shroomin Brain Boy

|

man... cam you are a fast one... quite frightingly fast!!!! had a day off from work or what???I must be doing something wrong when I paint stuff... I never am so fast and good...

your casts now really are mindblowing... and I see where you mentioned the "battle damage"... turned out convincing enough after you worked on the areas...

as for stench... well I recently primed my halftrack on the balcony...and my wife also complained only little about the smell... when I use washes tho... curiously she complains way more....(I have to add that I have no sense of smelling of my own...so all a mystery land for me where smell is concerned...so I ask these as a guidline for future endeavors...)

and another question to you, you mad maker of wonders.... after your very inspiring work on the big shoota yesterday I tried my hand in some shoota work too... but I gotta say the drilling of the cooling holes in the barrels is a work that really tires my hands... how on earth did you get them so perfectly aligned and so even too? do you need a special tool for that? a pull down rig for the drill? or are you "just" the better and more patient worker?...

seeing all this I feel privileged to have you share your works with us mate!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 08:40:39

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Battleship Captain

|

Good job doing your first casts cam. Think of air traveling through the mold when you cast. This really means think of how the piece you are casting will sit, and how the mold will sit and how the flow through that piece will act. Look for pockets where things get trapped and add a thin channel. Best of luck.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 11:57:53

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Near Golden Daemon Caliber

|

Hot damn, looking excellent

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 12:38:13

Subject: Re:Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Thanks guys,

Question: How tall is an ork dredd these days?

@ Vik. The smell isn't too bad. The gun barrel cooling holes. Well I pre drill by hand usually a 1mm hole then "ream" it out bigger with the tip of a scalpel blade. Trust me they are not that accurate. But it is quick.

Oh and no patience what so ever so can't be that.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 13:01:00

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Shroomin Brain Boy

|

lol...I did use a scalpel quite often in that fashion too... but well... feeble attempts at best... I think I am still at the low end of the learning curve on this one

and no idea on the dredd.... Automatically Appended Next Post: but I'd be interested in some data on that subject too... and for that matter a kan too...

|

|

This message was edited 1 time. Last update was at 2014/07/04 13:01:22

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 13:35:52

Subject: Orkishness - the thunderfarter years. yes thats a surfing ork!!

|

|

Gargantuan Great Squiggoth

|

Bloomin auto append.

Kans are 50mm tall to the top of the bodywork, plus a few mm for exhaust. And width wise they fill and often overhang a 60mm base.

Automatically Appended Next Post:

This is going to auto update on me but hey....

So todays efforts so far.

Made a box...

And every box needs either tracks or legs, ......legs it is.....

Some square tube....

Some hips... oh and rough up the box.

KNee's!....

Sorry skipped a bit, got excited......

And I am still mucking around with the casting/mouilding......

Onwards.... more later I hope. Hope he is not too tall, but then I don't really care.

Thoughts?

|

|

This message was edited 2 times. Last update was at 2014/07/04 16:39:33

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 19:41:36

Subject: Re:Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Is 'Eavy Metal Calling?

|

Nice work with the molds, the track is looking awesome and I'll love to see some single tracked Ork-bots. The newest kan is looking promising as well  .

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 19:42:57

Subject: Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Rogue Inquisitor with Xenos Bodyguards

|

Nice! a screatch-built Dreddy! Go Cam!

|

"Your mumblings are awakening the sleeping Dragon, be wary when meddling the affairs of Dragons, for thou art tasty and go good with either ketchup or chocolate. "

Dragons fear nothing, if it acts up, we breath magic fire that turns them into marshmallow peeps. We leaguers only cry rivets!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 19:46:29

Subject: Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Near Golden Daemon Caliber

|

I really like the legs... they look like they might actually work! Y'know, unlike a lot of orky goodness, or marine dreadnoughts, these look like they could allow your dread to move at a frightening pace to close on it's targets, good work. Still amazes me what you can do with plasticard.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 20:20:34

Subject: Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Battleship Captain

|

Excellent start to a dread. About 6" tall if my memory serves.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 20:48:21

Subject: Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Shroomin Brain Boy

|

the dredd looks very good already... for this you build it unlike I would... so this is an interesting journey...

and indeed this looks like a fast pacer...

somehow I really have a hard time making convincing mechanics... this is a problem you certainly don´t have!

as for the casts... is your resin black/grey?...seldom seen...

but what has been casted in the top right corner???

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2014/07/04 22:19:57

Subject: Re:Orkishness - the thunderfarter years. it's just Dredd full!!

|

|

Gargantuan Great Squiggoth

|

Thank you all,

@ Vik. Resin is white, those bits are made with that metal putty I keep on about, sets in about 1 minute. Demoulds no worries. perfect for these bits.

The other bits I will sort later for your amusement.

So did a bit more, here you can see why I needed those control panels...

Thanks for all your support.

|

|

|

|

|

|

|

|