I carved some time out of my shcedule to finish the case the other night.

First, I used a kitchen knife to bevel three sides of the top half of my faom block. Now it fits into the case and the lid closes easily over it.

Next, I needed to cut holes. I saw that kutzmon used pipe for his hole cutters and loved the idea. I went to Lowe’s to find 30mm, 40mm, & 50mm pipe. I found the copper coupler he mentioned and confirmed that it is ever so slightly larger than a 30mm base. I looked around and the biggest fittings they had for their metal pipes were 1.5 inches (~38mm.)

I grabbed an associate and explained what I was looking for and what I was doing. About half way through his eyes glazed over, confirming my earlier impressions of Hardware Store employees. They’re great at locating a specific product or explaining the common home repair in a codified step by step manner, but get a little panicy when asked to step out of the box. I let the poor man off the hook and said I’d think of something.

Quickly, I found a

WD-40 that looked to be a good size. I held the 40mm base of my Hunter up to the bottom of the can and found it to be a perfect fit. The

WD-40 is slightly larger than 40mm. Hopefully this extra space will decrease the frustration of inserting and removing units from their holes.

Unfortunately, I spent the next 45 minutes going up and down every isle looking for something in the 50mm range. I found nothing and walked into the garden center to think outside. As I walked out I saw an insect repellant can that was smaller than spray paint and larger than my

WD-40. I compared it base to base with my Ironcald and it was perfect. Relieved, I grabbed another bottle of spray adhesive and checked out.

When I got home, I emptied both the

WD-40 and Bug Spray into a 5-gallon bucket . I drilled a small hole in the base of each and was glad to find there was no pressure left in either can. Then I tried to cut the tops off each can. I placed the

WD-40 on the table and used a few clamps to hold it in place. I first tried with a hack saw. The can kept moving around. The harder I tightened the clamps, the more it deformed. The more it deformed the less usefull it would be as a home made circle drill. Also, excess

WD-40 leaked out and made everything slick. Eventually I gave up and cot a chop saw with a metal cutting blade. This worked MUCH better. The edges were a little jagged and

raw, so I smoothed them out with a flat file.

I next sharpened the edges with a dremel tool. I’ve never used the sharpening attachment before, and I have to say it was excellent. The

DW-40 and Bug Repellant cans deffinately took on a pretty sharp edge in a few seconds. The copper pipe, however, was a pain. It was so think it took forever (30+ Minutes) to sharpen. I changed the stones a few times to make sure that wasn’t the issue. In the end, the pipe was only pinted, it never got “sharp.”

I next laid out my foam and prepared to cut the holes. I kept in mind the ridges in the case as I planned my holes. I put the sharp end down, pressed lightly, and twisted gently from side to side. The 50mm and 40mm worked like a dream, straight down, and back out. The hole in the top of the can allowed air to escape and prevented the air from compressing the foam. The copper pipe was less ideal. It was shorter than the depth of the foam. I had to compress the foma around the hole to get it all the way down. After 10 30mm holes I gave up. I feared tearing the neighboring holes. I grabbed my file from earlier and hammered the handle down into the pipe so I could have a handle to hold. This dulled the blade again. I spent some time sharpening it and it worked servicably. It took more force and cut a more ragged hole than the 40mm and 50mm tools, but it’s good enough.

Next I made the foam floor for my now drilled out walls. I laid out a layer of crafting foam and sprayed it and the bottom layer of the thick foam with glue. After CAREFULLY laying the foam in place I set the case ontop of it and the speakers + amazon box ontop of that.

I handn’t been careful enough. The front most edge has three holes that are only mostly covered. At this point there’s not much I could do, and the gap they leave is so small that I’ve decided to leave it as is and move on.

Next, I trimmed the excess bottom foam and cut out a path for the case interior hinge arms to fold down into. I found a razor blade at this point and the cutting here is much smoother.

Everything fits into the case. I’ve got 88 holes. My Cygnar collection is ~45 models right now, so I have pelenty of room to grow. I’m realy looking forward to a set of

Tempest Blazers and maybe a few more casters.

There’s only one complaint. My wife got me the Two-Player battle box for christmas. I love it, but those darned Khadoran jacks are tall, and the Protectorate ones can’t keep their chains down. So far, the Kahdorans are surviving well enough and only stick up < 1/8 inch. I had to break the protectorate jack’s fist and chain off though. Eventually I’ll magnatize it and move on.

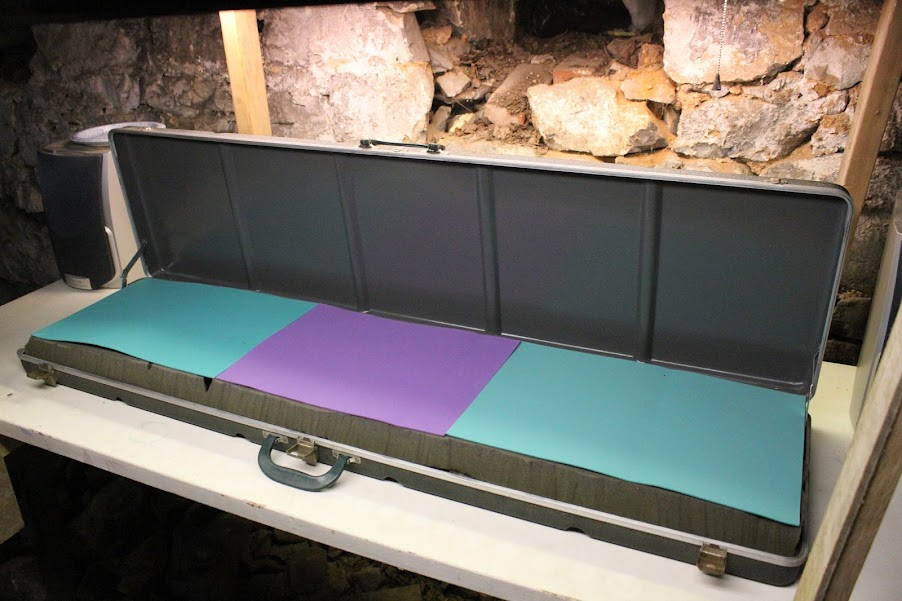

Now for the topper. I simply laid out three sheets of the same thin foam I used for the base and close the top. No glue, not special cutting, no nothing. The case holds them in place and the foam ensure no model hits the case directly. When I carry the case by it’s handles, the models all lay on their sides. The holes are just large enough that they don’t move around overmuch.

All in all, I’m considering this a success.

Now, all that remains is to paint it blue and add a gold Swan to it. Not sure when that’s going to happen as my wife will be spearheading that portion of the project. In the mean time, I have a gun case that carries my gun mages. Squee!