| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2021/01/12 17:18:42

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Tough-as-Nails Ork Boy

|

Hey I'm sure this is answered somewhere in the thread, but what exact model of the 3d printer did you use? I've been hesitant to jump into the market because I wasn't sure how the mini's would turn out but this thread convinced me it's possible to make good minis!

|

God is real! |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/12 23:24:47

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

Kaptin_Grubkrumpa wrote: Kaptin_Grubkrumpa wrote:Hey I'm sure this is answered somewhere in the thread, but what exact model of the 3d printer did you use? I've been hesitant to jump into the market because I wasn't sure how the mini's would turn out but this thread convinced me it's possible to make good minis!

Most of what I've done I've done it with an Anycubic Photon original or an Elegoo Mars 1. Both are great, but both are "obsolete" right now, in the sense that are 2k color lcd printers. You should be looking at mono lcd printers, preferably 4k.

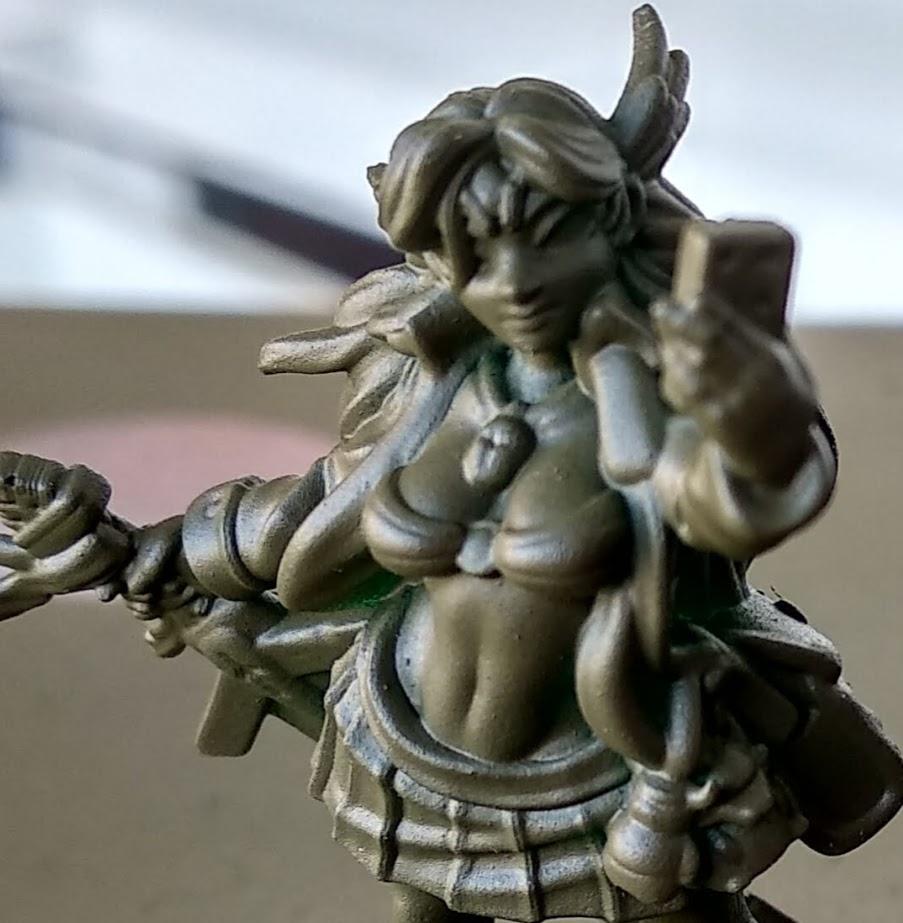

Also, tax:

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/13 16:54:49

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Tough-as-Nails Ork Boy

|

Well if they're obsolete they should be less expensive, right? Thanks for answering, this thread is awesome!

|

God is real! |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/13 17:25:31

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

Kaptin_Grubkrumpa wrote: Kaptin_Grubkrumpa wrote:Well if they're obsolete they should be less expensive, right? Thanks for answering, this thread is awesome!

They are indeed (you can get a cheap resin printer for even $120, but I'm not sure it's worth it anymore.

See, the important, the really important difference, is the change to mono screens instead of color.

Color printers just use a standard LCD made for a phone. Importantly, this means it has Red, Green and Blue filters to create color.

However, the printers' light source is on the border of violet and UV. This means 2/3 of the filters block nearly all of this light, and even the blue one filters a fair bit out. This dramatically lowers the light making it to the resin, massively increasing exposure times required. It also means more light is absorbed, increasing damage done, shortening the lifespan.

Monochrome just doesn't have the RGB filters.

In simpler terms, it means you go from 8s exposure, to 2s, and 400 hours before LCD failure, to 2,000 hours. ( Approximately, these numbers are highly variable. )

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/13 17:31:20

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Courageous Questing Knight

|

Everything took a big jump, even the base Elegoo Mars, just before the holidays. You could get the 2k base Mars before for around $180, now it is $230 or so on Amazon. Let the market cool a bit and you should save some money any any printer you choose.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/13 18:17:02

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Plastictrees

|

Did I mention your epic army is looking AWESOME! Keep up the good work sir

|

Read 28-mag.com yet? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/14 09:22:51

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

tauist wrote: tauist wrote:Did I mention your epic army is looking AWESOME! Keep up the good work sir

Heheh, thanks! ^^

So, one of these squads is printed at 0.05mm per layer and the other at 0.02mm per layer...

Also, no, they're not the same squad with the minis moved around

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/14 21:13:57

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Plastictrees

|

What printer are you using to get 20 micron prints? I've been trying to research these things and I've yet to find a single low cost resin printer which goes down to 20 microns (which seems to be the seet spot for my eyes anyway). Most of them only go to around 50 microns..?

|

Read 28-mag.com yet? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/14 23:27:02

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

tauist wrote: tauist wrote:What printer are you using to get 20 micron prints? I've been trying to research these things and I've yet to find a single low cost resin printer which goes down to 20 microns (which seems to be the seet spot for my eyes anyway). Most of them only go to around 50 microns..?

20 microns per layer means thickness, the Z axis. Most printers are able to do steps of up to 10 microns on that axis.

OTOH, on a DLP printer the resolution on the XY axis (the resolution on each actual "slice" or layer of the print) is dependent on the definition of the LCD screen it mounts. For example, the original Anycubic Photon has a 2K 5,5'' screen, so it allows for a max resolution of about 47 microns on the XY axis. OTOH a Phrozen Sonic Mini 4k has a 4K 6,1'' screen that allows for a max XY resolution of 35 microns.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 05:32:20

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Imperial Guard Landspeeder Pilot

On moon miranda.

|

Digging the Iron Warriors and Star Wars stuff, those Droids look fantastic.

|

IRON WITHIN, IRON WITHOUT.

New Heavy Gear Log! Also...Grey Knights!

The correct pronunciation is Imperial Guard and Stormtroopers, "Astra Militarum" and "Tempestus Scions" are something you'll find at Hogwarts. |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 07:57:55

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

Thanks man ^^

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 08:51:20

Subject: Re:My adventures and desventures in 3D printing

|

|

Plastictrees

|

Albertorius wrote: Albertorius wrote:After my first prints using the newfangled Photon, I continued doing some more tests:

And then I started to try and push the limits of the printer further... until then I had only printed stuff at 50 microns per layer, which, as far as it goes, is actually the thicker recommended layer height. So next I tried to print the same model at 50 microns and again at 20 microns, to try to see how much of a difference would that make. Yhis is the mini I tried it with:

Primed, because that green gak doesn't really takes well to photos:

Now, first things first: 50 microns is more than enough definition for most things, and works really well for minis. But still, as you can see the difference is noticeable in photos (almost not at all with the naked eye, though). And it is even moreso when you actually zoom in:

50 microns:

20 microns:

I was referring to the print examples in this post.. Here the 20 microns is looking great! so you can achieve this "20 micron" result even with a 2K printer? But I thought they only go to 50?, I'm confused..

|

Read 28-mag.com yet? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 12:37:33

Subject: Re:My adventures and desventures in 3D printing

|

|

Dashing Super Valkyrie Flying Ace

|

tauist wrote: tauist wrote:I was referring to the print examples in this post.. Here the 20 microns is looking great! so you can achieve this "20 micron" result even with a 2K printer? But I thought they only go to 50?, I'm confused..

Yes, as I said I'm talking about layer thickness here: what you see in the 50 microns pic is the more pronounced layering, stepping or stair effect that a thicker layer (50 microns per layer) has in comparison with a thinner one (20 microns per layer). But that's exclusively on the X axis, on the "height" of the print (not really the heigh of the mini, because you will usually print it at an angle, though). The XY axis, or the "screen resolution" of the print, is in both cases about 50 microns, which is the resolution of the lcd screen (2K).

In other words, in the 50 microns pic you can more easily see the separate layers of the print because they're thicker.

|

|

This message was edited 2 times. Last update was at 2021/01/15 12:39:09

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 14:35:52

Subject: Re:My adventures and desventures in 3D printing

|

|

Plastictrees

|

Albertorius wrote: Albertorius wrote: tauist wrote: tauist wrote:I was referring to the print examples in this post.. Here the 20 microns is looking great! so you can achieve this "20 micron" result even with a 2K printer? But I thought they only go to 50?, I'm confused..

Yes, as I said I'm talking about layer thickness here: what you see in the 50 microns pic is the more pronounced layering, stepping or stair effect that a thicker layer (50 microns per layer) has in comparison with a thinner one (20 microns per layer). But that's exclusively on the X axis, on the "height" of the print (not really the heigh of the mini, because you will usually print it at an angle, though). The XY axis, or the "screen resolution" of the print, is in both cases about 50 microns, which is the resolution of the lcd screen (2K).

In other words, in the 50 microns pic you can more easily see the separate layers of the print because they're thicker.

So even the in printers that only state 50 microns as their resolution, layer thickness is actually a very meaninful parameter as well; these two values form the overall printing resolution, and then the lift speeds and layer curing times affect how perfectly the print rendering itself occurs (values which are also synergistic with resin type and the size/weight of the model etc).. Ok, I think I'm starting to uderstand all this a little bit!

Cheers

|

|

This message was edited 1 time. Last update was at 2021/01/15 14:36:20

Read 28-mag.com yet? |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 14:44:07

Subject: Re:My adventures and desventures in 3D printing

|

|

Dashing Super Valkyrie Flying Ace

|

tauist wrote: tauist wrote: Albertorius wrote: Albertorius wrote: tauist wrote: tauist wrote:I was referring to the print examples in this post.. Here the 20 microns is looking great! so you can achieve this "20 micron" result even with a 2K printer? But I thought they only go to 50?, I'm confused..

Yes, as I said I'm talking about layer thickness here: what you see in the 50 microns pic is the more pronounced layering, stepping or stair effect that a thicker layer (50 microns per layer) has in comparison with a thinner one (20 microns per layer). But that's exclusively on the X axis, on the "height" of the print (not really the heigh of the mini, because you will usually print it at an angle, though). The XY axis, or the "screen resolution" of the print, is in both cases about 50 microns, which is the resolution of the lcd screen (2K).

In other words, in the 50 microns pic you can more easily see the separate layers of the print because they're thicker.

So even the in printers that only state 50 microns as their resolution, layer thickness is actually a very meaninful parameter as well; these two values form the overall printing resolution, and then the lift speeds and layer curing times affect how perfectly the print rendering itself occurs (values which are also synergistic with resin type and the size/weight of the model etc).. Ok, I think I'm starting to uderstand all this a little bit!

Cheers

Exactly so, yes ^^. There's a fair amount of variables, and you need to account for the properties of the specific resin you're using, but honestly? It's not even that hard. IME, resin printers are much easier to operate and maintain than FDM printers, up until cleaning and post processing (and FDM supports are evil incarnate. They hurt).

Glad to be of help

Also, just finished painting Padawan Ahsoka Tano, or Snips

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 14:53:02

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

The New Miss Macross!

|

I really liked it until you called her Snips, AL Guy!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 15:02:43

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

This one's not old enough to be called anything else

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 15:49:02

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

The New Miss Macross!

|

Just resize her to season 5+ proportions.

Joking aside, nice job!

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/15 16:20:04

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

[MOD]

Fixture of Dakka

|

Those B2s look nice and chunky, the larger shoulders look a lot nicer than the FFG ones.

Nice work on Ashoka.

Do you fully cure the resin on the sabers? I have printed off a couple of saber wielders (Mara Jade and Revan) and found that its impossible to keep the sabers straight when I fully cure them, even after hot water bending they just bend back again and it really irritates me.

|

On parle toujours mal quand on n'a rien à dire. |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/16 11:49:35

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

ingtaer wrote: ingtaer wrote:Do you fully cure the resin on the sabers? I have printed off a couple of saber wielders (Mara Jade and Revan) and found that its impossible to keep the sabers straight when I fully cure them, even after hot water bending they just bend back again and it really irritates me.

It's fully cured, yes. I'm assuming it will depend on the angle you print it and how you position the sabers during curing, as that will lock it in place. Pretty sure that hot water bending will do little with UV resin, due to the layering (meaning, it should follow the layers and the way it cured as a "default" form, instead of the mold).

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/19 14:36:13

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Courageous Questing Knight

|

I have done hundreds of minis with super thin swords and such and never have a bending issue, unless I wait to do a full cure for a few days I noticed some may droop slightly and have to straighten before doing the uv cure, then they stay fine.

If you get excessive droop after printing, maybe try to increase your layer exposure by a half-full second or so - this will cure the mini a bit more before you do the full cure.

As far as the layer lines and what to choose, here is what I found out for my Elegoo Mars:

- Small and super detailed minis - .02-.03 and turn any blur or AA off.

- Not so detailed, but small minis - .04-.05 and set AA to 2

- Larger minis with good details - .05-.06 with AA at 2 or 4

- Very large minis - .06-.08 with AA at 8

Obviously the thinner the layer the longer it takes to print, but if they are small and you orient to shorten the height, it is not so bad. Another trick is you can generally use a shorter cure time when using thinner layers - for example when using the Siraya Tech Simple I go about 8 seconds when at .07-.08 and can go about 5.5-6 seconds when at .02-.03 layer. Hope this helps...

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/20 11:11:56

Subject: Re:Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/20 15:24:59

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Courageous Questing Knight

|

Super nicely done!!!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/20 17:24:21

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Omnipotent Lord of Change

|

Great job on Anakin's CW pallid skin and sunken eyes. Snips is rocking too.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/01/20 21:44:41

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

The New Miss Macross!

|

Agreed! I can't help but feel that those painting details are trying to foreshadow some sort of darker turn in the character though...

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/02/05 17:51:50

Subject: Re:Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

|

|

This message was edited 1 time. Last update was at 2021/02/05 18:06:41

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/02/05 17:55:31

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Leader of the Sept

|

They look amazing. Interesting to see the layer lines on the rhinos, but not on the vindicators. Do you churn the rhinos out on different settings, or are they just supported at a different angle?

|

Please excuse any spelling errors. I use a tablet frequently and software keyboards are a pain!

Terranwing - w3;d1;l1 Terranwing - w3;d1;l1

51st Dunedinw2;d0;l0 51st Dunedinw2;d0;l0

Cadre Coronal Afterglow w1;d0;l0 Cadre Coronal Afterglow w1;d0;l0 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/02/05 18:06:17

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

Flinty wrote: Flinty wrote:They look amazing. Interesting to see the layer lines on the rhinos, but not on the vindicators. Do you churn the rhinos out on different settings, or are they just supported at a different angle?

Just adjusted the layer time settings correctly for the next print ^^

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/02/08 14:52:29

Subject: Re:Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Dashing Super Valkyrie Flying Ace

|

I'm testing color schemes for an astartes opfor for my loyalist IWs. So far I'm testing these ones, one finished, one not:

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2021/02/08 17:52:44

Subject: Albertorius' 3d Printing, Painting Modelling Blog [Lastly big load of SW Legion stuff]

|

|

Leader of the Sept

|

The metallic green is lovely, but possibly too similar to.your iron warriors in that its shiny metallic. The red is definately fundamentally different, and obviously fits the bill as a "red force" OPFOR, but overall I think the green is nicer.

|

Please excuse any spelling errors. I use a tablet frequently and software keyboards are a pain!

Terranwing - w3;d1;l1 Terranwing - w3;d1;l1

51st Dunedinw2;d0;l0 51st Dunedinw2;d0;l0

Cadre Coronal Afterglow w1;d0;l0 Cadre Coronal Afterglow w1;d0;l0 |

|

|

|

|

|

|