32724

Post by: fiorehellheart

Welcome to my Project log, I'm Rory. I've started this project log as one last attempt to build myself a Warlord Titan before I head off to university in 3 months time. I've intended to build one before, but never quite had the motivation, nor time, so it didn't get beyond the planning stage. However, last night I finally started on my Warlord for the first time and now I hope I will be able to see it through to the end. This project log, which is being posted on the Ammobunker, Warseer, Work in progress and Dakka Dakka simultaneusly is intended to both inspire others like myself, and to ask you guys to give me to motivation to complete this project, by not letting me give up. This is why I will be writting as much as I can about why I'm going about it the way I choose, if this rough guide helps just another person to go on and make a titan I'd consider it worth the time.

I'm going to warn you before hand that even though there are only 8 photos in this post, I discuss each quite thoroughly, I'm sorry if you get bored. I'm suspicous that even among fellow 40k players i'll go into so much detail that you'll look as bored as 'normal' people do when I try to explain warhammer to them. So just feel free to simply subscribe and look at the pretty pictures, I won't be insulted. The same will probably be true of the whole project, if you like detail though, then I hope you'll enjoy it too.

Okay, so this is my progress so far, I've printed my first copy of the templates off onto some card (180gsm) and traced onto my plasticard (0.5mm) to cut the first shapes. To trace onto the plasticard I've tried various things, the best of which I found was to poke a sharp pin (I actually use the end of my circle cutter) through the card whilst holding it securely to the paper, the only other possibly improved method is using sticker based A4 paper to print the templates onto directly. This would then be fixed to the sheet whilst cut, then removed afterwards. Rather irritatingly I've been unable to find any printable A4 sticker sheets, if anybody has a link to anything decently priced I'd be greatful. The pieces laid out onto the card in the picture are for the toe, in another post when I begin to assemble the structure I'll explain more about how I intend to achieve the toe shape. There isnt really much to go on right know, I'm waiting to order some glue. The rest of this intial post I'll explain the rest of the design as a starting point.

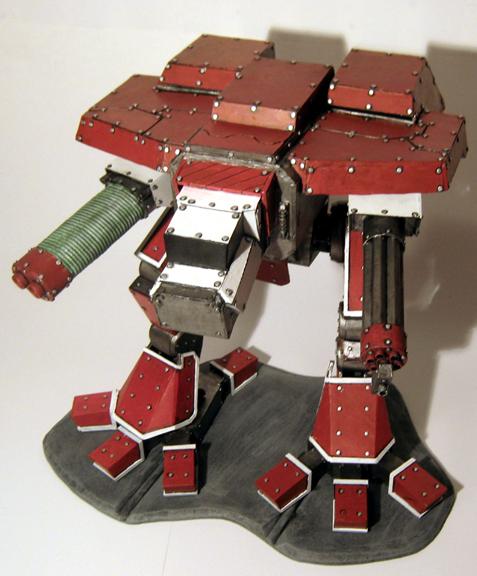

This is the latest image of my planned Warlord titan. It's quite obviously just a 3d model, and this is what I spent the last few years tweaking and adjusting in my spare time, whithout actually building it. I think the most obvious thing, as I intended, is the departure from the classic Warlord profile in the Epic model. Mine is curvy, makes it a bit sexier I thought. It's more than that really though, from the outset I wanted to be able to make something that would fit in with, at the time, the Mars pattern Warhound titan. But my first designs were not too curvy, and it was only when the Reaver was released that I begun to be able to change the design getting it to fit more with that aesthetic. From that I pulled stuff such as the gun shapes, the leg design and the toes. Although the toes are more from the gamesday prototype and other parts from the Warhound, ie the crotch armour plate. The part of the titan that I was most able to seperate and begin to design on my own was the torso. shoulders and head.

This picture shows much better my attempt to blend the boxy Epic Warlord into the curved Forgeworld titans. I took the inspiration for the abdomen from the apocalypse rulebook Warlord illustration, although mine now curves at the edges rather than being a simple extruded arc of a circle. The large upper shoulder plates were inspired by converted dreadnought I found online, credit to Vaaish here. From that model I really liked the style given and after altering the shape but maintaining the same impression, I got what I wanted. The render doesnt have the carapace weapons on yet and they will be added to the flat section of each of the top shoulder plates similar to the Reavers carapace weapon, with a similar style.

The 'lower' shoulder plates that extend further out are the most differently designed component to any other titans I've seen. I decided to slant both them and the upper shoulder plates so that the silhouette of the titan further lost the boxyness of the Epic model, whilst keeping the hulking proportions. This picture also shows the gun and arm better, the gun quite obviously 'borowed' from forgeworlds Reaver. The arm on the otherhand is similar to some of my favourite titan models, the very limited production dreamforge levithan mortis blockhead and crusader variants. A good interview with some decent pictures of the titans can be found here. I hated that I was never able to get my hands on one of these as they're fantastic, thankfully the designer has made some new titans, of which I definitely recommend you look at. The other part shown is the head. This was probably the hardest part to figure out, and I'm still not entirely happy with it, I simply don't think I can do better. In my opinion the Forgeworld heads are easily the best parts of them, both have complicated compound curves which my overly analytical mind can't understand to well, as I can't model them on a computer so I can't easily build them. Yet both look great. In making mine I felt that copying a knights helm had the right kinds of straight lines and curves that made it look noble enough for a titan.

This shot of the back of the titan shows most of the block detail I plan to add to the technical parts. I've obviously excluded stuff like rivets and a lot of plate detail though, especially on the caps to the cylindrical joints and gun ends which I intended to have a combination of cogs and circles layered on. I also haven't included multitudes of small pipes and cables, things that add detail when loosly scattered about mechanical surfaces. I'm not going to be sneaking any bits of building in, instead I will rely on layered sheets of plastic card to form evenly detailed surfaces across the model. I've always been of the opinion that a model with only one or two detailed areas looks much worse than a model with a lot of mediocre detail because of the contrast. So I don't intend to add anything like parts of plastic model kits unless absolutely necessary.

The last design picture is showing the part I'm intending to build first. This also borrows heavily from the Reaver, with the curved armour surfaces, but is still quite different, for one thing i'm not using a ball joint on the ankle. I know that the ball joint is much better for stability, but I didnt want the hassle of loads of pistons. Instead I only have a couple on each leg, at the ankle and back of the knee. A different departure in design the the curved heel plate, this was something I had from the begining on the intial model thanks to the picture of the Warlord in the Apocalypse rulebook. Something too interesting to leave off I thought.

On the Reaver titan the armour plates on the 'toe' part of the leg were attached to pistons fitted on a line to the base of the foot. From seeing in build photo's it's always appeared to be incredibly awkward to position correctly. Instead of this on my titan the toe armour plates are attached by a connector to the core shin piece alone, with the intention of raising or lowering along this plate as the leg tilts. I'll be able to explain this better one built. I do however intend to attach some form of ribbed tubing between the toe and toe armour plate but this again is something that I can do at a later stage so isnt on the render. This was all part of my intention to reduce the number of pistons I would need to build and position, it also solved a problem I've seen on one or two reavers, where the join of the toe armour piston doesnt appear fit correctly due to the angle they're posed at, it isnt designed to rotate along one axis where the position of the leg means it should, so doesnt fit correctly. I may see if I can find a good example picture of this for another posting.

This is a schematic styled picture I threw together for fun. It does however bring me to the issue of scale. As you can see I decided that 26 inches, excluding carapace weapons, was sufficient. There are several reason for this, but the biggest I found wasn't a matter of converting the scale from epic, or from converting the scale from fluff, but instead going with what looked best in comparison to everything else. Whenever I see people attempt to calculate scale from fluff or models it always seems flawed given that no uniform scale exists across everything, everybody knows that marines aren't truescale, and that a rhino couldnt fit 10, and nobody agrees on fluff sizes, so I see these calculations as almost impossible to reasonably argue for. On the otherhand it's quite easy to take a look at a rhino, a few men and a reaver, then to scale up or down to the best fitting size for a game. It's even what the guys at forgworld appear to do, check out the reaver titan design video by will hayes where he talks about printing different scales to find a best fit compared to other models. Part one here, and part 2 here.

These last two pictures help to demonstrate what I mean, it puts the 10.5" Warhound and 16" Reaver alongside my Warlord scaled to 26". This size just appeared the most managable but fitting too. Much bigger made the others appear too small, and much smaller didnt fit either.

The final picture is an edited version of The Dreadnote's scale diagram from Dakka Dakka, taken from The Dreadnote's gallery here. As it's the best scale picture I've found online I hope he doesn't mind that I'm using it to justify my scale, although I would suggest the Imperator titan is a tad small. Thanks to him for making the image. My only ptoblem is that the heights of our Reaver titans differ, I believe it's because I measuered to the carapace top, and he measured to the weapon top, but if anybody has a reaver would they mind measuring and posting a picture here so I can figure our which is correct. You might also notice that it's listed at 24" inches on the left hand side, but it's still scaled correctly anyway.

Now I suppose I should thank anybody who made it through all of my rambling, well done! If you have any questions please ask me and I will do my best to answer them. Other than that feel free to give me your opinion on my design, I can still change things if I haven't built them yet and I'd love to see how this goes. And if I forget to update this thread within the week, just send me a PM, which should hopefully reach me and get me to do my best to show some progress.

11914

Post by: Nephilem

Looks good! Curious though, is it a feature of your particular variant that it not have the shoulder/top mounted weapons, or just something you wanted to avoid on your build to keep the curviness of the model?

Eager to see how this build turns out.

32724

Post by: fiorehellheart

Nephilem, yes, the shoulder weapons should indeed be there. But I just keep on forgetting to put them there, it's just something that I'll get around to towards the end of the model. I need to decided on weapon choices first and it wasn't important for the scaling, as i only measured to the top of the shoulders.

9217

Post by: KingCracker

Cool, another Titan build. Ill keep watch for sure

41111

Post by: Daston

Very interested in seeing how this goes! Good luck

34644

Post by: Mr Nobody

I look forward too seeing more.

60173

Post by: Frostbitten

I enjoy seeing these come together, looking forward to seeing progress!

36040

Post by: Rhich

oh am I soooo going to be following this !!!! Great work so far.

55324

Post by: bibblles

That's quite an ambitious project. Looks like it will be just a bit taller than my titan.

60129

Post by: Scout Sniper J.

I'll definitely be keeping an eye on this project! (=

32724

Post by: fiorehellheart

Thanks for the response so far, really encouraging, I've just got to try and not disappoint anybody now  Also, nice titan bibbles, classic, but well built. In terms of progress I got some more of the templates cut out yesterday, I'm going to be doing a bit more cutting, but I should hopefully be able to start building soon. Later I'll try to get some more pictures to show you what I've done, and hopefully some renders to show you more of the foot area being broken down as I intend to be building. Please continue leaving questions, nice comments, or even nice questions

55324

Post by: bibblles

Yeah, just so long as you avoid the mistakes I made, don't start with the torso and expect to just stick legs on it... that will not work. Build up, feed first like blackadder did.

514

Post by: Orlanth

Nice you are trying to scale it properly, its about 2" too tall, and that height includes carapace weapons, 24" is right, as Dreadnotes wallchart says.

You could use torso mounts for the two other weapons, it could also be used to explain away the extra height of the model.

32724

Post by: fiorehellheart

@ bibbles, That's pretty much why I first decided to use the CAD route unlike most people. It lets me have a complete understanding of my model far before it's even started. I'm totally happy with stuff like proportions after a lot of testing, and testing with the computer is so much easier than it would have been if I made mistakes and had to do things repeatedly. If I can manage to be even partly as detailed as blackadders i'd be pleased. His models are just remarkable feats of engineering, that Thunderhawk, Warhound and Warlord. I think it's mostly about layers, and layering simple detail over and over, a little like layers in a painting I guess. But that's not saying it's easy, we'll see how it goes when i get started constructing I guess.

@Orlanth Check out what I said before. I know that 24 is the generally decided height by most scratch builders, but I felt that it could be just a bit bigger and still come out good. That said I largely based my chosen height on comparisons with the Reaver and Warhound, and if I should have measured the Reaver to the top of the gun rather than the carapace then it might need to be smaller. But on the other hand, even if I am wrong in measuring, I don't think the extra couple of inches will look bad, and will just make it look a bit more imposing than I'd intended. Still within the realm of acceptable with either height. The guns will also be on the shoulders, I just need to model them. Think I need to do that soon, a few people aren't noticing what I said on the other forums too.

Right, I've got another update, so on with the pictures.

Thought I'd start off with a scale image tonight, it's not going to be the smallest of models really.

This one actually shows what I've been up to. I continued with cutting out templates, as I'm still waiting on my glue to arrive, hopefully it'll be here within a few days. This shows the first pieces of the base of the foot, that's the octagonal plates to the left, they along with the strips on top will form the inside of the foot. Basically being the strengthening structure within. The 'male' part of the ankle joint, that's the series of 5 circles beneath that. The ankle caps, that's the circles with cog detail placed on top, they will have a spacer between them before being smoothed using car body filler. A technique I will use on all the curved surfaces. The parts of the toe middle have also had some detail cut out for them, and a bit of detail for the toe end built. Not loads of progress I suppose, but I work slowly most of the time, everything has to be perfect.

I built this using superglue, it's the circular pipe connector that can be seen on top of the toe ends. A piece of pipe will stretch between this and the toe armour plates. I cut the inside circle and then wrapped a strip around the edge which I glued. This is also raised a little with another circle underneath, and the small bit of detail was made with a bit of thicker plasticard I had lying around. It's not much but I wanted to actually build something rather than cut pieces out.

This is just showing the cog detail, where I've also penciled in the placement of rivets. To make the rivets I have a bag of 1mm diameter steel balls which will be superglued in, I only haven't done this as I want it to be the last thing I do on the part.

I also made a new render which should show the breakdown of the feet a little more. In the first picture it's just the base of the foot, octagonal with a beveled edge. The toe end and middle. The Heel plate and ankle caps, which will have that cog pattern on. The second bit shows the addition of the leg column and the toe armour connectors. Those connectors are fixed, and the toe armour plates will move up or down depending on the rotation of the leg. The last two show the armour plate connectors, toe armour pieces and the full armour plates. I just thought it was handy to show you it in more pieces than before.

A few people liked the technical drawing so I made another one. This has the scale of about 2 inches to every square. It's intended to show the various angles that the leg is able to manage. If rotated much more to either direction there's intersection with the leg armour plates and the other parts of the foot, but I'm happy this should be enough articulation for the stance I want.

That's pretty much it for now though, really needing that glue to arrive soon. Because it hasn't I've been doing some work on the templates I use instead, I need to unfold the model for the thighs and upwards. I also haven't gotten around to modelling those shoulder weapons, but when I do i'll be sure to update my images to show you how they change the silhouette of the model.

48376

Post by: Capitansolstice

I officialy am following this! Epic

17738

Post by: Briancj

I like the THOUGHT that is going into this project, Sub'd! Good luck meeting your deadline!

53085

Post by: Kiryu Mk 3

these plans look legit as hell.

60129

Post by: Scout Sniper J.

I can't wait to see it painted!

23828

Post by: eledamris

Your titan is far better thought-out than mine. I built mine around materials that were available from the local Lowes and around the house. Give a bit of thought to the materials you're using, however. It may not look like it, but they get very top-heavy when you add the weapons, and plasticard won't stand up to it. I suggest a wooden frame for at least the lower half. If not that, then at least some sturdy PVC with resin poured through the center to strengthen it.

32724

Post by: fiorehellheart

@capitansolstice, epic? not quite, different scale

@briancj thanks, I'm quite doubtfull I'll manage to meet the deadline, but I can hope

@kiryumk3, Can't say if I'm sure that's a compliment or not, I'll take it as one though, so thanks

@scoutsniperj, Paint wise I need to figure that out, I think I'll go with red and gold, as in the render's I posted. Other than that 'm not too sure how I'll manage it, If anybody has any good tutorials for strong red's and gold's I'd be grateful, also weathering both moderate and strong. I'm also thinking about getting an airbrush or some kind, I know that I'll have brush lines all over the massive plates otherwise.

@eldamris, In terms of strength, the lower half should be cast in resin, which I expect to provide sufficient weight and strength. Further to that I've always seen people say that these things need a wooden or pvc support because they're collapse otherwise, but I've yet to see one where somebody built one that actually collapsed in plastic. If I saw something like that which suggested to me I am doing something wrong then I'd be inclined to change materials, currently I expect that as long as I keep to the planned internal supports, effectively a grid, it should easily be strong enough.

I finally got my glue and another big sheet of plasticard, so I'm going to be able to start constructing now, hopefully I'll have something nice to show you soon.

If any Mods are reading is it possible to move the thread into the more appropriate painting and modelling blogs section, I didn't realise it should have been there instead when I made the thread, thanks.

32724

Post by: fiorehellheart

Finally some decent updates and some progress, as having gotten the glue I began building things. Picture heavy post ahead.

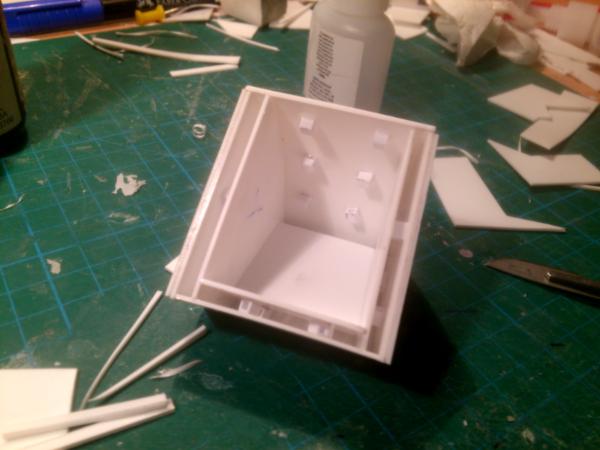

I started by building the base of the foot, I plan for most of my parts to build a form of internal structure, for support. With the base I Cut spacers of an even width and an extra few octagonal plates. These were used to build a weblike structure inside that's used to add strength.

This is the assembled internal structure for the main base part, I took special care to align the 3 octagons on each edge. Didnt work that well though so I had to sand it perpindicular.

When adding the side plates I leave an edge over where I intend the final edges to be. This then gets sanded down and leaves a neater finish than I can manage by cutting first.

After sanding those edges flat to the next edge, the next ones are placed over those, these will be sanded next.

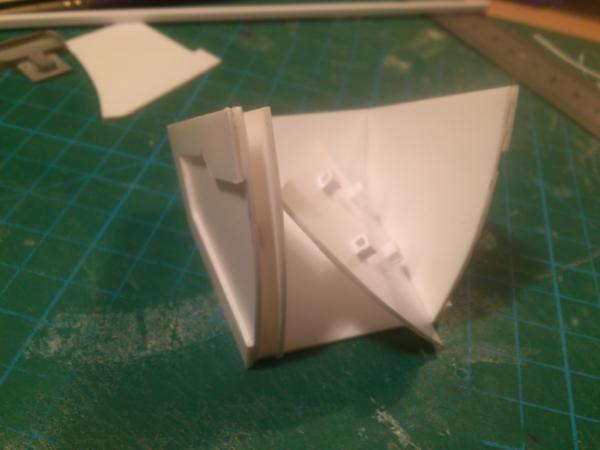

The next part I built was the toe mid piece. Same as the other piece, it involved using an internal structure, parts slightly bigger and sanding them down again. I still need to put some surface detail on, but first I need to give the curved surface of the joint part using filler.

The toe end. Internal structure, sanding down again, this needs another plate on the top, and then the filler over the curved area, then the plan is to put edging and rivets on.

Bit of scale shot of the foot, it's getting quite big, and I still havent begun to build the curved heel plate or done the ankle circle things.

This is the jointed part of the ankle. I've done the internal structure and the curved circles, I have yet to sand the edges even and then I'll be able to add filler to give the curved joint. Onto this I'll put plasticard detail. The two other pieces to the left will cap of either end and need to be edged, and need to have detail plated on.

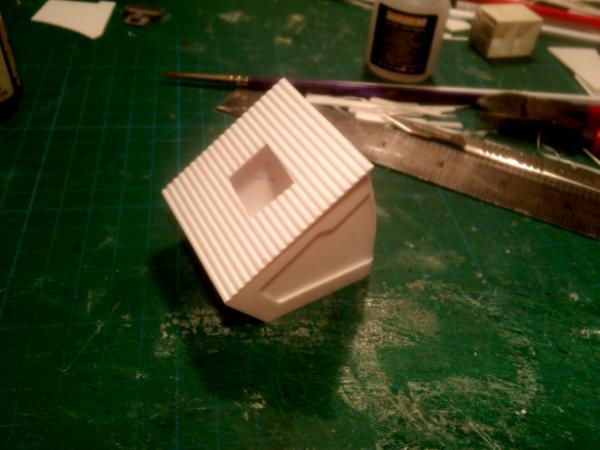

This is the part that connects the toe armour plate to the leg, I fancied something different to the foot parts, and I know this is an interesting piece so I built it. Still in need of sanding and edging and detail though.

Just the complete shot of all the work I got done yesterday, one thing visible is a sort of grey paste on the circle piece for the top of the toe end, this is a plastic paster i'm using to fill some gaps and even it out.

I'm progressing forward as much I can and hopefully I'll be able to update soon with the real interesting work when I get to forming curved pieces with the filler material. As usual, ask question if you with or just leave helpful comments, thanks.

14062

Post by: darkkt

1) Im amazingly impressed by the work done here.

2) Im not sure how this is going to work on the table-top (wont it take up all the table, and be brushing its head on the ceiling!??!)

Sitll, awesome in concept and design - love it.

36535

Post by: Midnightdeathblade

Im glad you plan on adding shoulder weapons, it adds much needed bulk to the main torso, but I do like its sleak streamlined curves. It almost looks agile. Great concepts. Keep it up!

55324

Post by: bibblles

darkkt wrote:

Im not sure how this is going to work on the table-top (wont it take up all the table, and be brushing its head on the ceiling!??!)

He raises a good point, the lucas patern warlord (like mine) is 24 inches (26 with carapace weapons), you are aiming for what? 26 before carapace weapons, so nearly 30 inches once those are installed...

I hate to say it after you've gotten started, but your scale may be too large.

That said, it probably won't matter at your FLGS but it WILL matter for transporting it because 30 inches is going to be immense in a car.

44232

Post by: DijnsK

subscribed! i wanna see where this awesome stuff is going!

40213

Post by: DiDDe

DijnsK wrote:subscribed! i wanna see where this awesome stuff is going!

I totaly second that!  really great work so far!

32724

Post by: fiorehellheart

@darkkt & @bibbles, thanks darkkt, In terms of using on the table I'm not entirely sure how I'll manage either. From the beginning this wasn't a model I wanted to build for the gameplay, and still isn't. Instead it's something I greatly enjoyed designing, am greatly enjoying building, and hope to enjoy painting it too. Afterwards I'll have a model that's far more for showing off that anything else. That said I would like to be able to use it in a few large apocalypse games. Usability wise I'll probably put a base on the thing, which would add strength at the cost of room, but is something I think I'd need to do, I doubt it would move all that much during a game however so this might not be too bad. Also, I took some parts into my flgs to ask the opinion of the manager, too small he says, but I think he'll still let me use it.

@midnightdeathblade, Thanks for the compliments, the agile thing I like, it's something that the mars Warhound captured really well, same with the Reaver too.

@DijnsK Thanks for the encouragement

Some more progress and pictures.

The toe armour piece has now been mostly plated right, I have a panel I intend to redo however. In the last photo of the two you should be able to see that the narrowest end to the right doesn't lie flat. When I sanded the rough edges down I didn't notice it hadn't glued properly, letting me over sand it down, I tried to get it to work but having looked at it I'll just redo the plate there. Shouldn't be too difficult.

This is the connector piece I showed before with the edging added. I still need to sand down the edging at the ends, but the middle parts I'm satisfied with, I need to put rivets on this afterwards then should have my first finished part.

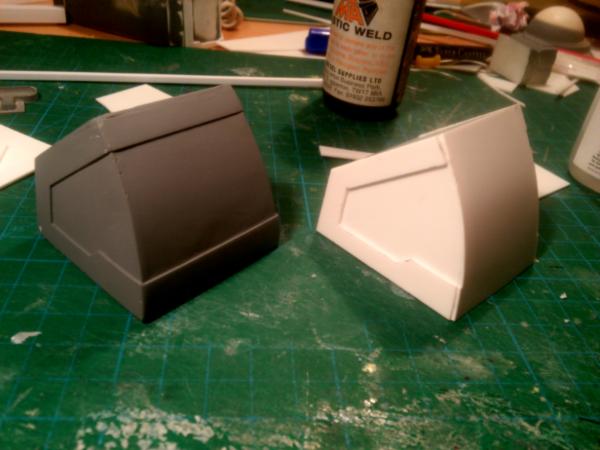

This is the ankle cap circle thingy, I could really come up with a definitive name for this part... It's been reinforced with spacers between the two circles and is waiting to have the filler applied so that it is sanded down to a cylinder. The cog detail is glued onto another circle which will go on the side, as the other circle has been placed. The detail on the cog itself was redone because I wasn't quite happy with how even the smaller indented circles on the edges were. Hence the comparison shot, I know there isn't a huge change but felt more comfortable with it a little neater.

Somewhat blurry picture of the toe mid piece, I only need to apply the filler now, it's been sanded down on all sides and I'm happy with the seamless appearance. I've been using my phone for the photo's, but I might need to steal a camera that can handle a bit of macro in order to show some of the finer detail when I get started.

I've blutacked in place the circle connector thing to show the placement. The grey plastic paste stuff, which is a mixture of old sprue and some of the liquid solvent I use, makes it appear unsmooth, but it actually is. Again this is showing the more seamless effect of the sanding, and is another piece that's awaiting the filler before I can add the last detail to it.

The Edges on the foot base have also been finished, now I need to begin to build another slightly raised section on the part to give the beveled edge. This is why I've left a lip to the edges. This will let me push the angled plates into the edge so that they have some extra support, and that when it's sanded it appears even.

Not sure how much work I'll have done today. It's my school's leavers ball so I'm occupied for the evening. But I'll try to do some stuff during the day.

28261

Post by: RutgerMan

this is SWEEEEEEEEEEEEEEEET! keep up the good work ;D

32724

Post by: fiorehellheart

Thanks rutgerman

Short update for today's stuff

I fixed the problem mentioned before with the over sanded plate. Didnt take long as I expected which was handy.

I also got around to using the filler, this first application is more of a rough coat. After sanding this down, hence the smooth parts, I'll apply another coat and sand that down, hopefully that will leave me with a very smooth curved surface, onto which I can build the edging and the box for the connector to attach to.

The ankle cap was also filled, here you can see another part that's lower than the desired level hence needing a top up before sanding again.

Same again with the toe, although this is much more roughly filled as I didn't mix enough to completely fill the cavity, I should have reduced it's size really, but it will be fine after a second coat another day.

The ankle joint. This needs the second coat obviously, but I may decided It's easier to search for an appropriate diameter tube, that's if this doesn't work well enough, but I have hopes it should suffice.

The toe midpart has been filled in enough, this will now get close to me finishing it as I need to add some small detail now and it's effectively done.

That's what I've been up to this morning, I may get some more work done when I return from my prom. I often stay up to between 4 and 6 in the morning doing work, I find I think clearer then. So there might be an update tomorrow morning or if not, then the evening.

17738

Post by: Briancj

Out of curiosity, why are you using filler, instead of, say, thin plasticard, shaped around?

32724

Post by: fiorehellheart

Good question, it's largely because when I've tried plasticard curves I could never shape it properly. It always creased where I wouldn't want to, and it was horrible to try and glue down. If I used thinner plasticard to reduce this, then other problems arose like the glue making it sag when using layers to give strength, or slight sagging where it glues to any internal support vanes. On top of that it sands amazingly, the filler, so it's far easier to adjust if something does go wrong. In terms of the cylinders it's so difficult to use plasticard too because you have to eventually join the two halves that wrap around the piece together, the filler gives a seamless finish. The only problem I'm aware of for filler, is that it soaks up the solvent like a sponge, and it then doesn't dry properly, it becomes rubbery, I think this is because it's partly styrene and porus. It means I can't use much solvent afterwards, and none on the surface of the filler, but superglue should suffice. Hope that all makes sense

17738

Post by: Briancj

Makes sense to me. You seem comfortable with the process, and are making fast headway.

Eventually, someone's going to come in here, and ask you to cast up a copy for them.

43845

Post by: Skipphag da Devoura

Dat iz purdee!

Gotz ta git me spannaz an' mekboyz ta staht up me Gargant pictures!

Very cool.

32724

Post by: fiorehellheart

Well, If I seem comfortable in what I'm doing it's probably because I've tried to think of every possible detail as well as I can. I have a tendancy to 'over analyse' in that way, probably one of the reasons I'm naturally good at physics. It just means I can feel I understand every part of the model in great detail, and because it's taken me such a long time to design I've just slowly absorbed tons of information online in how to do things and which parts of my model they apply to. The filler technique for example, although I did link to the Will Hayes video where he talked about it, it's not where I learnt it. I learnt that several years ago through a website called the 405th, which is a halo replica prop forum. They use this technique to strengthen and detail the costumes they build. The reason I was on that website in the first place was that they use the same technique that I use to create the basic templates I construct from. This very long chain of knowledge has just been built up over the years to a point that I'm very comfortable to use as much as I possibly can, and whilst I know that there are bound to be parts of which i could do better. I think I should at least be able to manage a satisfactory level with the knowledge I have. That probably makes me sound cockier than it should, but I'm just saying I've done my research

Well, if somebody did ask, that would just be cool that they think that highly of the model. Yea, I'm going as fast as I can, It's been a long time coming this project, and I'm not going to waste the time that I'm inspired enough to run at full speed. I also anticipate large delays when I get into the casting and the large armour plates, so I intend to give as much time as possible to those.

Thanks skipphag da devoura, much appreciated

Also, Dakka Dakka's fast becoming my favorite forum, you guys seem much more enthusiastic and involved than other places, and whilst I appreciate it might be because this thread is in what I anticipate as a high volume sub forum, being the general P&m compared to P&M blogs section, It's been really friendly and welcoming, thanks

I just got back from my prom, at 3ish, good night, but I'm going to see what I can get done whilst I'm still awake, I don't need sleep... Much...

17738

Post by: Briancj

As long as you stay in the Painting and modelling section (and the DCM section), you're fairly safe. The various game sub-forms are good, but stay out of the YMDC threads.

*ALL* good hobbyists, all good modelmakers learn from a long, long chain of events.

For example, my skills are from making regular models, some prop work, and Model Railroading, as well as a light background in "Fine art". Which, of course, makes me laugh when people "Discover" something like Verdigris of "Zenithal" airbrushing...and claim them to be new, or just discovered. These techniques have existed for decades, if not centuries (Verdigris).

Anyways. I really enjoy the fact that you ARE writing out the "Thought process" with step by step examples. Unlikely folks are going to follow your steps, but for the ONE PERSON who does...you're there for them. I try to do the same in my plog, when I do something 'weird', like salvaging clear plastic canopies.

Keep up the work, get some sleep, glad you had a great prom!

32724

Post by: fiorehellheart

Yea, I guess you're right about the learning thing. Thinking about it, it's normal, but just seems such a different way to the school learning I've spent most of my life receiving. What you mention is also why I'm doing it the way I am, because I know that this is the kind of thread that I myself would love to have found being done by somebody else.

I started of tonight by beginning the curved heel plate, it was quite daunting and I think I was avoiding it slightly, but I pressed on. This is the way I'm choosing to give it internal structure, the two walls are assembled from lots of fixed width rectangles. Because I was sure to make all the angles, right angles, when I joined two of the plates together to make the curve, they stand perpendicular, meaning the entire wall has a uniform height. This just means I can easily build another layer on top. The walls are slightly behind the edge of the true curve as I will fill the created gap with the filler, smoothing to give the curved plate.

This shows the end curve where a gap exists so that the ankle caps don't intersect. To build this I cut each of the vertical pieces according to my templates and spaced them correctly before adding spacers between to provide support. The spacers also guarantee they are perpendicular. I built two of these, and this is just showing the placement on the heel piece. Compare this to the back plate of the foot on the renders if anybody wasn't sure what I meant.

I will be continuing to build the centre part to match the height needed. This is just using the same wall method as before, take ages though so it shall be completed another day. Once that is completed I'll begin to apply filler just as in the other curved pieces.

I have finished a piece, just the toe armour connecter, but it is detailed as much as I wish. For the rivets I'm using some 1mm diameter steel balls. I got them on ebay on some craft shop. To place them; I drill a hole with a 1mm drill bit of sufficient depth, then I place superglue in the hole, put the rivet in the hole, then use a 0.5mm piece of plasticard with a hole in it as a spacer to level the height of the ball using a ruler. If this method isn't clear just ask and I shall try to make a picture tutorial. Also, as a tip, when drilling the holes I used a template, with pre-measured holes drilled in, this way I wasn't measuring on awkward pieces, or just guessing.

I feel comfortable enough to say that I have completed the toe mid piece too. Although there are slight details on it I would wish to change, the effort to re-do the piece wouldn't be worth it. Instead I'll accept it was an early piece and that I made some possibly avoidable mistake, but shall just have to learn for in the future. The curved section on the top with the slats is a style I intend to reproduce on the the joint for the ankle. I like the way it looks and think it should scale up well enough. The only problem with that style of curve is making the slats appear individual enough. To achieve that I had to cut individual slats and then sand the edges so that they more resembled a trapezium. The slanted sides meant that the gap was much more visible. I did these ones by hand, but I shall try to assemble some form of jig for sanding the larger slats down when I reach the ankle joint.

I also completed the ankle cap detail. In addition to the rivets I added a raised trim around the edge of the cog and inner circle. It was just a bit more detail that I felt helped to make it seem more 3 dimensional. It was difficult to achieve however and took a long time with gluing parts and holding them in place to dry, as I had no suitable sized clamps. The effect was worth it however...

...Not that it matters. This is just a picture of some plasticard stuck to my table. If you haven't guessed it yet I managed to knock over the small bottle of plastic weld that I use. It flooded over my plasticard covered desk and stuck loads of loose plasticard onto the table, even my speakers were melted into place. In terms of damage to my model it could have been much worse. Just managing to splash over the octagonal foot base. As the ankle cap detail was on top of it though, it glued them together and effectively melted all of the detail on the ankle cap piece. The foot base fared better, with just slight cosmetic detail and no lasting structural damage. I may choose to only replate the part which shouldn't take long and will fix it easily. The rest of the parts were saved as I was storing the pieces with the filler on in a plastic bag, and the two finished parts on my shelf just above the desk. As a side note I use the plastic bag as for a while after setting the filler gives of an unpleasant smell, so I bag them up when not in use. The bag itself was splashed but saved the contents.

I will hopefully manage another update tomorrow, but after that I'll disappear for 5 days on a short holiday. Soon as I get back though I'll be working away, and no doubt I won't be able to stop thinking about the model whilst on holiday

34644

Post by: Mr Nobody

Rivets, rivets everywhere.

32724

Post by: fiorehellheart

Well, That's the plan

53821

Post by: AnUnearthlyChilde

Are those ball-bearings your using for rivets? If so, bloody ingenious method, wish I thought of it lols!!!

32724

Post by: fiorehellheart

Yea, they are. I also have the contents of a water filter cartridge, but because they're mixed in terms of size I find that the predefined diameter ball bearings are easier to use. Still not exactly very easy to use though, as drilling a hole in the wrong place is a lot worse than gluing a flat backed rivet in the wrong place. Really I'd like to buy some of the premade ones from the grandt line but these will do for now. The other method I have tools for is the hole punch, I use a leather punch. The only problem with that is that the rivets are directional, as they are rough on one side. So I have to take more care when placing them down. Also the diameters available are 2mm and above, so it wasnt suitable. Something I might have a go at trying though is some of the lion roar rivets from here, http://www.antenocitisworkshop.com/wargaming-materials-tools/augmentables-nuts-rivets-bolts.html, They might be the best of all of them.

17738

Post by: Briancj

Well, if you would just read some of OUR threads  you'd see that cheap rivets are best done by buying a NWSL or Micromark Chopper, getting some plastic rod of the appropriate size, AND GOING TO TOWN.

It allows you to make any size rivet, as well as full-on bolts, using hexagonal stock from Evergreen or Plastruct.

--B.

32724

Post by: fiorehellheart

Ahh, if only i could buy a chopper, I've wanted to get one of those for years, could never quite justify the price, I'd rather spend the money on something like an airbrush instead. That said it would massively increase the speed if I were able to use one. Takes me ages just ensuring all my angles are right angles...

In terms of rivets though that's how I first did them, sort of, by using a knife and some rod, I could never regulate the height of the rivets well enough and although it would be easier I quite like the uniformity I can get with the balls. The other rivet method I've seen, but don't know much about is a type of hand held punch that's got a spherical shaped hole in the end of the tool, so it digs out hemisperes, something like that atleast, as I said I can't remember much about it.

17738

Post by: Briancj

From Micro-Mark:

Was: $23.95

Sale Price: $20.75

Item #: 84046

Way, WAY less than an airbrush.

53821

Post by: AnUnearthlyChilde

Dude, your looking at roughly £20 for the micromark version including delivery!!! Invest in one, you won't regret it

44232

Post by: DijnsK

im soooo glad i subscribed to this thread! looking good so far

60129

Post by: Scout Sniper J.

How are you going to lug around the Titan when it is finished? (especially if you ever try to take it on an airplane...)

22413

Post by: mwnciboo

Wow, it might be quicker to build one of these for real than out of plasticard. Honestly I admire your perseverance on this, never mind the cost of the materials, this is a labour of love.

58484

Post by: Doofry

It is all looking awesome, to say i am impressed is an understatement!

Just a thought and i know it is too late now, but for your templates, you could have bought a can of spray adhesive to mount the templates on the plasticard, and the good thing about it is that you can reposition it.

Keep up the fantastic work!!

57210

Post by: DemetriDominov

Epic stuff. Following this for sure.

32724

Post by: fiorehellheart

@briancj and @anunearthlychilde, I looked on their website and whilst it is only $20, it's another 20$ for shipping to the UK. Which puts it back to being expensive. I did still end up ordering something though. What I got admittedly isn't as nice as the NWSL chopper or the micromark chop-it as it's made from plastic. That said though it doesn't look like a bad product at all, and at £8, I'm happy to get it instead. Bought from here, http://www.proopsbrothers.com/acatalog/Online_Catalogue_Paper_Card_Cutting_12.html, and pictured below. I intend to be doing a complete review as soon as I receive it, I don't think many of the warhammer modellers will have heard of this, the only references I found to it were crafty and model railroads. If it works well It'll be fantastic value. One downside is the stops are different, and I may have to figure a way to place a ruler along the back like on the chopper, but this is something I think I can manage.

@dijnsk, I'm glad you're happy so far, I'm hoping for it get much better though

@scout sniper J, I haven't thought too much about that so far, but I expect I shall want to buy some custom foam packaging from somewhere like battlefoam. This way I can figure out the best layout and then have it professionally finished. Something similar to these two examples I hope.

http://www.dakkadakka.com/gallery/347523-.html

http://www.dakkadakka.com/core/gallery-viewimage.jsp?i=329874&m=2&w=800

@mwnciboo, Thanks, You're right about the love thing, but I may turn to hate this thing if I manage to spill my glue again

@doofry, Thanks as well. Regarding the spray mount though, I have tried it but it wasn't strong enough to stick properly, and just ended up ripping away mid cutting. Which wasn't great and just made it worse. The pin method I'm using now feels the most effective for the low effort required, don't have to wait to glue and don't have to cut out parts ect. That is unless I'm able to find these A4 sticker sheets.

@demetridominov, Thanks for tagging along with me on this

Well, I'm back from holiday, aside from trying to find a job and then doing that job, I'm intending to spend most of my time on this for the next few months. Whilst away I had a good chance to think about the construction of parts, and I think I'm going to buy some acrylic pipe. I've figured out that by combining different wall thicknesses and overall diameters I can minimise the cost of the piping by using parts for more than one place. For example I intend to use a 34mm OD piece on the male ankle join section, paired with a 40mm OD piece and a 3mm wall thickness for the female part. This gives an 34mm ID which means the two will 'telescope' to use evergreens terms. The The 40mm OD piece will also be used for the axle part of the hip. On the hip it will slot within a 50mm Od piece with a 5mm wall giving a 40m ID, again telescoping. This 50mm OD piece will also fit in a 60mm OD 5mm wall 50mm ID piece to give the biggest diameter section at the top of thigh. As the knee will also use the 50mm OD for the male part, the female part will be the 60mm OD part. Also the inside of the calf will use the 50mm OD piece. In this way I only need 4 pipes, instead of the probably 7 or 8 diameters I was going to be making using the filler. This does mean that the diameters are slightly different to those on my original plans, but I'm sure that nobody else but me will have noticed, and that plasticard detail would have altered this anyway. It's going to be interesting figuring out how to effectively cut the tube accurately, but I'll get around to that once I've received the order.

In other news I've been able to turn more parts of my 3d model into templates, so I'll print those and begin on stuff like the thigh and hip whilst I wait on the pipes. I'll also attempt to finish the toe and toe armour pieces as soon as possible along with repairing the foot base to completion and the heel plate. Lots to do for now but I will update as soon as I'm able to. Lastly, Anybody have any thoughts on names? If people can give me suggestions I'd take the ones I most enjoy and do a small poll.

32724

Post by: fiorehellheart

Update as I promised then

I continued with my work on the heel plate, with the intention to reach a point at which I could begin to apply filler to give the main shape of the piece. When I returned to it I realised that my previous method of cutting rectangles and forming a wall was very time wasting. I get the exact same result by just bending a single piece in a curve.. Felt smart realising that half way through the part. Well, I continued in that manner and had completed the internal structure as shown in the pictures.

I then placed an edging onto this, going all the way around the part. This was done wider than the internal structure so that when I smooth the filler out it sands evenly. Where the plasticard peeks through the filler it can sand slightly uneven because the filler and styrene are different materials. It will sand like this at the edges but it won't be as noticeable here, and I intend to be adding an edging onto the piece anyhow which will go over any unevenness at the side. This part is now done until I begin to apply filler, I may need to buy some more however as it is a large part.

I also got around to rebuilding the part that was melted when I spilled the glue. This time hoever the cog is slightly smaller and I fancied adding a thicker edging around the edge and keeping the same edging on the inside of the cog, except only on the cog part, not on the central circle. Unless there's significant protest /i felt this looked better and intend to stay with it instead. The parts aren't currently glued together, but I will do so when I add the rivets to the piece.

This is the filler I use, having just picked it up at halfords one day. I may try other brands in the future, but this stuff seems good for now. Today I did however realise that I hadn't been using enough of the catalyst. The material on the parts such as the toe end that I had already done was not completely mixed and as a result it softened part of the plastic along the edge of the toe end. I plan to use the filler to repair this but it is a little annoying. I hope that it's because I haven't mixed it well enough with enough catalyst, the material under the softened plastic parts was still soft, so I think I'm right. The second picture is just the parts right after applying the filler. I applied it to the toe armour piece, then the ankle cap then the toe end, and you should be able to see that as it has hardened in the 15 minutes or so of work time it's become less smooth to apply. Which is why I did it in the order I did, doing the most desired smooth piece first.

The two pieces are now sanded and very smooth to touch, smoother than the plastic in the case of the toe armour piece even. Aside from the gouged holes in the toe end piece, I'm slightly unhappy with the toe armour piece too. Where I used supports on the inside the outside plastic has bowed inwards, I think this is because I haven't used enough supports. You can just about see this on the photo where, at the edge of the filler and plastic, the sanding didnt give a straight edge but a bowed line, this is because the join is uneven due to that bending between supports. In order to fix it I think I should be able to apply some of the filler and then sand this down into a right angle, but I have already attempted to minimise the visibility by sanding some of the plastic down too. I think I'll spray paint the piece white too in order to better see how smooth the joins are and where I can improve the piece, likewise with the toe end.

This is the sanded down ankle cap piece with the detail placed on top. The two variations are so that I could see which way is best for the positioning of the edging I've placed on the part. I prefer the edging at the top as in the left picture, but I would like other peoples opinions too, bearing in mind the positioning from the earlier renders.

I still have a long way to go, but I intend to begin working on the main thigh part and the hip soon as I've only got to print the templates out before I can begin. Tomorrow I hope to have been able to get some work done on the base of the foot, and possibly the filler work on the heel plate. Hope that satisfies everybody's interests for now

17738

Post by: Briancj

Hope the chopper works out for you! Again, thanks for showing us the FULL development process. While most people won't follow your lead, seeing the design-in-progress shows us all the techniques you're using, and hopefully someone will use them in THEIR project.

Good luck with the job search!

57210

Post by: DemetriDominov

There's more detail in that ankle than there is in some armies....

32724

Post by: fiorehellheart

Haha, thanks guys again. I've been a bit busy the past couple of day's, I'd forgotten about going to a theme park so I missed most of a day then and I've been job searching too. I do have some updates however.

To continue on the foot base I begun by building the spacing and then placing the top part of the foot base. I had intended to use plasticard to do the angled edges, but I considered that this would end up weaker than the alternative use of filler, so I used that instead and plan to sand down until I have crisp edges. In terms of detail I plan to add riveted plates, but little else as other things will need flat spaces to attach to the foot base.

I also used the filler to attempt to repair the edges on the toe armour piece, and to fill the holes in the toe end piece and level the base of the piece too. Once these two have been sanded down I think I'll complete them in just a few days as the detail is minimal.

I thought I'd run down the rivet process for anybody who's interested in it. First I drill the holes in the part, I go all the way through as otherwise they won't all fit to the same height. Once drilled I force the balls into the holes, but without glue yet. I also make sure to press each through so that the bottom of the ball is level with the bottom of the o.5mm plasticard. This ensures that half of the ball is above the surface, and half beneath, and means that all the rivets will be of equal height. Once placed I flip the part and then I apply the super glue on the bottom, this stops and from bleeding over the surface which happens if the glue is placed and then the rivet placed in the hole. Once this is done the piece is finished, and provided the spacing between rivets is even, they will look good. Even heights go a long way to adding a manufactured feel.

Also, I went to collect the chopper from the post office today, and I'll try to upload a review and some pictures soon. It seems suitable so far.

5462

Post by: adamsouza

This is coming alongnicely. Looking forward to seeing how it turns out.

53821

Post by: AnUnearthlyChilde

Dude, I could kiss you... you know, if it wasn't for the fact a) your a man (possibly?), and b) I have no idea where you live

keep up the awesome work!!!

12975

Post by: thesilverback

Great job and very informative can't wait to see more and finally the finished Warlord Titan.

61163

Post by: Brother maximus

Hey can you pm me a link to the templates

53960

Post by: warboss skul-krak

I'm very impressed by your work. cant imagine scratch building anything that big  cant wait to see your progress.

28327

Post by: mullet_steve

your doing really well so far but be cautious about how much hardener you add to your body filler because the more hardener the more it shrinks and shrinking may seperate the body filler from the plastic

32724

Post by: fiorehellheart

@adamsouza, thesilverback, warboss skul-krak, Thanks guys.

@anunearthlychilde, Haha thanks I guess...

@brother maximus, Won't do I'm afraid, the templates are a mess to say the least. Because of the way I work they're very incomplete, having no tabs or complete layouts, in many places just including a single profile panel type from which I figure the rest out through knowing the model really well. On top of that I'm just not all that comfortable releasing the past 4 years of work on this one model for other people to play with, somewhat selfish I understand, but I'm simply not very comfortable with it. Sorry, I have released templates in the past, and they should still be on either the bwc 1 or two. They're much older warlord templates, and aren't as mars smooth as my current ones, and are still badly designed, but they should still be good enough to build something from given enough determination.

@mullet steve, Thanks, I'll admit I wasn't aware of the shrinkage problem, having mixed too little catalyst and destroyed stuff with unset filler I've attempted to put as much in as possible without being silly. I'll try to be more cautious though. Given you sound to have more experience with it is there anything else that might catch me out? Like I mentioned before about it seeming to melt parts of the styrene, is that common?

More updates

I glued the ankle cap detail on, so the piece is completed for now. I next need to begin building the connector that holds this onto the foot base part.

I used the filler to fix the edge on the toe armour piece, so it's now straight enough. I'm pretty happy with it and I will start to put another part onto it, which is a box at the back, after which I will rivet and add plating.

I also sanded down the first coat of filler on the foot base, the edges are all crisp and I'm pleased with them and don't think I'll need much more than just one more coat of filler then a bit of detail, as I've said before however this is going to relatively sparse in detail.

I also started on the armour plating, however I'm not too happy with the design I've done and think that I will remove it and go with the detail I had in the 3d model. I didn't expect a departure from that to look any worse, but I'm not as pleased with it.

Not loads of updates, but something. I'm waiting to get a job before I begin the main parts of legs as I need to order acrylic pipe, and just don't have the money for it now. But I will try to do any detail that will go onto the parts, and much like when I waited for glue, will do as much as possible. Also, is anybody able to confirm what I believe and tell me that the solvent weld, dichloromethane, will bond acrylic to styrene? I did a small test which seemed to work but if somebody can confirm more thoroughly I'd be happier for it.

23695

Post by: J99Pwrangler

Very awesome fiorehellheart. Yes, is there a way to view the templates/ plans you used to make this?

53821

Post by: AnUnearthlyChilde

Fiore, I sincerely hope your casting these parts as you go, because it'll save you from making them twice

28327

Post by: mullet_steve

the chemicals in the filler will soften the plastic which is very common... I'd leave them to reset before you do too much sanding to be honest.

to avoid dipping (where the filler sands away quicker than the plastic ribs) I'd suggest making yourself some snading blocks... Take a piece of flat material which you can comfortably hold and spraymount onto it and the sandpaper then trim the sandpaper to fit.

32724

Post by: fiorehellheart

J99Pwrangler, See my last post, whilst I am roughly using templates myself I'm not going to be releasing them. Sorry for that, but thanks for the compliment

Unearthly, Yea, that's the plan, not just because I don't want to have to make them twice, but more because it means they'll all be the same. I'd prefer identical pieces even if it was more effort, which casting may well be. Even on parts of the stuff I've made it bugs me how imperfect they are, the octagonal base for example isn't exactly octagonal, which isn't noticeable, but annoys me to just know it isn't. At least if I cast them they'll all be the same. On top of that though casting looks like an interesting skill that I'd love to learn and have a go at.

That's what I'd expected mullet_steve, just something I'm going to have to work around then. With regards to leaving them a while to set IIll probably give a longer wait time on the larger filler areas, such as when I start the leg plates and shoulders ect, but I want to get as much done as possible so I've rushed of sorts so far. Nothings gone wrong yet and I'd like to keep it that way so I might slow down a bit before I get overly cocky. I'll also look into the sanding block, I intend to make some irregular ones when I do the legs plates anyway, so that I can sand the filler on the inside of the leg, but I'll get to that later.

More updates today, more pieces essentially finished.

I decided I really didn't like the plating look, so it was scrapped. Just thought I'd show what a mess I made of it. I'd used the plastic solvent so it was welded together, in future I plan to do the edgings all with superglue. It's much easier to separate the join of superglue and the residue can be sanded down more easily. The new plating is more angular than the other stuff, but it's closer to the render and I'm much happier with it. I'm also not too fussed about the angular edges as the Reaver toes are very angular in their edging, whilst the rest isn't. So I don't feel like I'm making too large a departure in style here. I also glued the housing for the connecting pipe between the toe armour plate and toe end piece. I'm not entirely sure how I'll do the connecting piece itself, but I at least doubt I'll put another housing on the underside of the toe armour piece, it would take up too much room and won't be seen due to the angle anyway.

This is the connector between the base of the foot and the ankle cap piece. I'm undecided on how much detail and riveting to put on this part, but I may have to do it heavily riveted to match the rest of the pieces, in the picture later on in this post it looks a little sparse. I've left the end unplated as I plan to use filler in order to match the height of the part to the position on the foot base as best as I can. It also isn't noticeable in the picture but I need to use some filler to repair some melting from overzealous glue usage, and uneven sanding. It's not the bst part I've made but I'll try to improve it.

For the plating on the toe armour piece I decided to start to introduce the curves into the edgings. I'm quite happy with the effect and depending on how I feel whilst edging other parts, my titan may end up more angular in terms of the edgings than the forge world ones. I still need to decide how and where to place rivets onto the edgings before these are finished though. Ideals I need a set of 2mm spheres that don't cost a lot of money, so far the only thing I've seen is ball bearings which are more expensive than I can use. I could use the leather punch pressed rivets, that are flatter and more disk like for the 2mm upwards rivets I want. I'll try some things out and come back with the results another time, but if anybody happens to know where I could get some 2mm spheres that aren't very expensive, I need a few hundred I think, I'd be grateful.

Lastly just a blu-tacked shot of the parts so far. I'm pretty chuffed at how stuff's going so far, although it is slower than I'd need to meet the deadline of October, it's faster than I'd actually expected to achieve. There is a larger image that's 1024x768 in resolution in my photobucket gallery here:

http://i852.photobucket.com/albums/ab86/fiorehellheart/Warlord%20Titan%20Project/Update%2010/10_08.jpg

If you want to check it out in more detail that the small images I use for the forum posts.

If anybody has any questions, just ask, thanks again.

32724

Post by: fiorehellheart

Ahh, fantastic, trust the hive mind to succeed where I'd missed. Although,you're technically wrong  It's under 6 quid, excluding VAT  still not too bad though.

It doe leave me undecided now on what to do. If I buy a lot, 500 odd, then I could use them with the holes, in which case I'd be making some big holes to make them flush, which could go wrong. Or whether to get only a few or so and make some green stuff molds of hemispheres so that I can just superglue the greenstuff parts on top. I'll need to look into some greenstuff mold tutorials, and try something out first, but I'ts nice to have the choice now, thanks.

On warseer somebody also suggested I look into a solvent dispensing pump bottle. I guess most of you won't know what one of those is, and I wouldn't blame you, but I've wanted one for a while after I found a you tube video demonstrating one. https://www.youtube.com/watch?v=myh8-zpJt9Q

I did a quick search and found one on ebay that I fancied as it was much cheaper at just 1.50, compared to the 22 I'd seen at my plasticard suppliers site. Just as with the chopper I intend to get one and try it out partly because It's something I haven't seen other wargamers use.

http://www.ebay.co.uk/itm/200ml-Cleaning-Chemical-Agent-Alcohol-Makeup-Remover-Pump-Push-Down-Dispenser-/390422022379?pt=UK_Health_Beauty_Nails_Manicure_Pedicure_CA&hash=item5ae6f748eb

27896

Post by: blood red 1

i plan to build a knight class titan one of these days, im gonna keep an eye on your project and see if i can get a few good ideas from what your doing

32724

Post by: fiorehellheart

Awesome blood red. Personally, I'd take inspiration from dreamforge if I were to make a knight. His new models are pretty much perfect and would just need the mars style armour plates and edgings to look complete, certainly all the working parts are there and it looks sufficently mechanical.

http://www.dreamforge-games.com/forum/index.php/topic,62.0.html just that thing with edging on the plates, at least that's what I'd look towards, hope that you might get what want with a bit of inspiration from here though

53821

Post by: AnUnearthlyChilde

fiorehellheart wrote:Unearthly, Yea, that's the plan, not just because I don't want to have to make them twice, but more because it means they'll all be the same. I'd prefer identical pieces even if it was more effort, which casting may well be. Even on parts of the stuff I've made it bugs me how imperfect they are, the octagonal base for example isn't exactly octagonal, which isn't noticeable, but annoys me to just know it isn't. At least if I cast them they'll all be the same. On top of that though casting looks like an interesting skill that I'd love to learn and have a go at.

Don't worry I'm the same, and so is Blackadder (another titan builder on here, he's doing a lucius warlord with interior currently). I've learnt to let go more though these days, as if I am the only person who see's the imperfection, then I can let it slide... otherwise I'd resculpt/redo pretty much all my models

keep up the awesome work dude, I am really enjoying seeing this come to life!!!

32724

Post by: fiorehellheart

I'm in total awe of blackadder, I followed his warhound build, which was amazing, and I really like his warlord even if it's the style I like less. We present pretty different methods me and blackadder, his is a somewhat more gung ho take it as it comes and build just the next part in the line before thinking about the one after that, where as I've planned almost every detail as well as I can, I even have a head interior planned already. His stuff's more detailed though, and I envy how he manages to do that stuff so well.

But yea, the perfectionism is annoying at times, when I can't let go of some tiny detail for example, but it does push me to do the best I can which I appreciate. And I hope it's likewise with yourself

53821

Post by: AnUnearthlyChilde

Lols Blackadder is far from gung ho tbh, he's OCD like myself so needs to do things ina logical step before going on.

oh of course, I wouldn't consider a model finished if I ever thought it was sub par... I love to convert more than anything, scratch builds less so as they are more time consuming, but as my entire Tyranid force requires converting in some form or another its get a tad tedious lols

32724

Post by: fiorehellheart

Hmm, after a google gung ho doesnt mean exactly what I'd thought it did, just means over excited about something, which I suppose he is, but I meant it to mean how much he sort of tries things as he goes, designing along the way. Not sure I'm making my point very well, but he's great anyway.

haha, yea, I used to be a converter, that's how I began proper modelling at least. Then I started to go bigger when I tried a warhouond, after that I also have a few orky constructs. An old bomber and fighter I scratch built, and an orky thunderhawk, I might get a photo of them just to show what i've done before now. All of them are in pretty bad shape after so many years, but I keep on telling myself I'll finish them sometime.. I was always more of an imperial converter though, making converted techmarines and such rather than nids, which I've never collected before. Might have helped the shocking gap in greenstuff knowledge if I had done though.

58575

Post by: Wh40kPicasso

Looking good so far, updates few and far inbetween but quality assurance is always appreciated!

53821

Post by: AnUnearthlyChilde

haha, I kinda figured what you meant anyways Fiore, even though he does it as he goes along, the thought process he goes through is amazing, kinda like yourself with it all tbh!!!

GS ability is just something that comes with practice, no matter what army you do really, its just a matter of practice imo, I don't think its something that comes naturally to anyone. Having said that I'm an artist and love to sculpt but yeah, I don't think any of my tallent (or lack of it lols) is natural

6825

Post by: The_Blackadder

Now this is how to scratchbuild a Warlord. Well drawn and thought out plans. CG illustrations. None of the hit or miss fumbling that I employ. It's a pleasure to see this come to fruition. I found your work on another forum and referenced it to here where I can subscribe.

I like the fact that you meticulously plan out your work. Not only does it rule out mistake but it's easier to replicate duplicate parts.

I almost have a hankering to attempt a Mars pattern as well for your amazing effort but I have so much scrap lying about I think I might cobble together an Ork Titan.

53821

Post by: AnUnearthlyChilde

The_Blackadder wrote:Now this is how to scratchbuild a Warlord. Well drawn and thought out plans. CG illustrations. None of the hit or miss fumbling that I employ. It's a pleasure to see this come to fruition. I found your work on another forum and referenced it to here where I can subscribe.

I like the fact that you meticulously plan out your work. Not only does it rule out mistake but it's easier to replicate duplicate parts.

I almost have a hankering to attempt a Mars pattern as well for your amazing effort but I have so much scrap lying about I think I might cobble together an Ork Titan.

Build a megga Gargant!!! I double dare you!!!

32724

Post by: fiorehellheart

Yea, I intended to put some practice in with greenstuff but never got around to it.

Thanks blackadder, I noticed your post on the ammobunker as well, think I've commented on your threads in there before now too. I think its quite interesting our differing approaches, as you said my planning and your 'hit and miss fumbling', which really does it a disservice. I don't know how you manage to do what you can as fast or as detailed as you do, it's taking me huge amounts of time to do just little things on this, part of the reason my momentum's slowing a little. Still, I'll keep slogging on with the plan. My votes for a lucius reaver titan next from you, some blend of the epic forgeworld and the mars forgeworld one, but I can also see the appeal of heading orky with scrap. I've only been doing this a short while but my desk looks like I'm building in a miniature scrap heap.

It's been a while coming, but I've got some more updates, again, not much but I have an excuse. A couple of days ago I felt that the foot base wasnt good enough, when I first sanded I did it on a tray that had a lip on the underside I hadn't noticed, meaning the surface of the tray was slightly raised above the surface of the table. When I sanded it meant that it bowed downwards slightly, so all of the edges on some of my early sandings are slightly curved. I've sorted this now and put a piece of wood under the tray to raise it so that it doesnt sand wrongly, but I'd already done the foot base. Because of this I decided to rebuild the foot base all over, so spent a long day recreating it so that all of the edges were perfectly flat and perpendicular. After I'd done this though I spent a short amount of time sanding the original one, which I'd already put filler on, and after a short amount of sanding the edges are close enough that it's not noticeable anymore. So in effect I wasted a good deal of time duplicating a part for no reason. Which is why the updates taken so long. I intend to learn from this lesson though...

After that I decided to get started on some other parts. These are the two pieces that will cap the end of the ankle joint tube. I've cut the circles to slightly less than the 34mm outside diameter of the pipe. This is so that when I get the pipe I'm sure that it will fit within the tolerances of the pieces and happily fit onto the end without much fuss. If there is a slight increase in size It's just appear to be more edging and not matter. Building this I'll say that the chopper was really useful, I used it to ensure that both of the trapezium type parts were correct using the adjustable angle guides and it was a lot quicker when cutting right angles for the 0.5mm width edging.

I haven't got and earlier picture, but this is the second coat of filler on the heel piece. I'm pretty much out of filler now so probably need to get some more, but as soon as I have done I'll be able to get close to finishing this. The inside isn't as close and has only had one coat of filler, but I have figured out how to easily sand it now. Using a large diameter piece of tubing that my plasticard was shipped in, I just wrap it with sandpaper and sand using that. Because the curve is smaller than the curve on the part it isn't perfect, but it's better than any other method of sanding I have and has worked well so far.

I also put a second coat of filler onto the foot base part. You should be able to see that now the edges are all fairly crisp, I've also been careful to get a very similar angle on at least two of the faces opposite one another, as they will take the ankle cap support piece. The sort of P shaped one. On the left of the closest edge in the picture you might notice that theres a slight imperfection at the corner. This is because I've almost sanded all the way through the plasticard whilst trying to fix the curve and the slight slant. As luckily it's the same only on the opposite face, I'll add some extra plating to this which will act as a placement guide for the ankle cap supporting piece. this should solve the problem and make it clear as to the orientation of the part, given that some of the faces are slightly dodgey fits It'll avoid misplacement by accident.

I decided it might help to give a diagram of the progress, and I'll try to update this picture every few updates. That way people can tell where I am in the build without figuring out all the different pieces I've built so far. Things coloured green are finished, things orange are a work in progress, and I haven't started the white stuff. So I've got a lot to go.

43845

Post by: Skipphag da Devoura

Holy Crap!!!! This is turning out beautifully!!!!

As to your research... Where did you find the dimensions? I've been trying to scale up the image from the Apoc book, based on what I know from the the Warhound, and it's pic... but it's coming out a little wonky...

I am a mechanical engineer, so I do understand how to scale... but it's still a little off...

6825

Post by: The_Blackadder

At the risk of this turning into a mutual admiration society I feel I must state that I find your drawings fascinating. I wish I had the wherewithal (read patience) to produce such drawings for my Lucius Pattern. Right now I am scaling down the carapace from my posterboard mock up. I'm glad I saved it as many times I was tempted to toss it during my move to new digs but by scaling it down by 0.9 it has saved me a lot of re designing.

I notice from your text that you are having a bit of problem with sanding. Forgive me from stating what you may already know but the information may be useful to those who follow these threads. I use two methods to sand: first on a flat and true surface such as a formica countertop I lay a full sheet of coarse sandpaper; good stuff such as 3M aluminum oxide paper 60 grit. Next I sand only in one direction. If you sand back and forth you can't help but start rocking and end up with a convex cut. anytime you sand or file, only cut in one direction.

My second method of sanding is a square and true sanding block. I cut half a dozen of these 5/4 by 3 inch by 6 inch blocks many years ago and affixed the sandpaper (3M aluminum oxide) with 2 inch double back tape. when the paper wears out I peel it of and apply new. Again only sand in one direction and it is helpful to rest the piece to be sanded on the table so your cut is clean and true. I also use a steel emery board for tight places although I lost my best one in the move..........Drat!

Once the piece approaches the scribed or penciled line I switch to a medium grit paper for the final dressing. As the edge will probably have glue solvent applied it isn't necessary to use any finer than medium grit. Once glued and the edge is squre but must be beveled I use medium or fine paper on block to true the edge.

I also use a really good and clean single cut file with a medium and fine tooth again only file in one direction not back and forth.

I'm going to copy this to my own Warlord thread because although I have stated this tutorial before it bears repetition.

60129

Post by: Scout Sniper J.

You might want to pick up the pace if you have two months left to finish...

(just saying)

34385

Post by: doktor_g

Holy hell dude. Don't use bond-o for the whole thing... you won't be able to lift it! Or there will be so much torque on the skeleton that you'll need a metal internal structure. Good idea though if you just are keeping it on the feet.

Great work! Enjoying the progress.

48211

Post by: Luckless

Really loving the work here. Is there any way you could post a link to the template you based all this off of? I'd certainly be grateful.

32724

Post by: fiorehellheart