| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 13:25:03

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Lady of the Lake

|

This is a pretty cool tutorial. @Captain Klaw: Any idea if that site will ship out material to Sydney. Also looking through the resins there, what would be a good one? I got a crazy idea for a custom Necron army and this would really help it

|

|

This message was edited 1 time. Last update was at 2010/08/04 13:25:31

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 14:42:24

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

@n0t_u:

I'm not entirely sure if they'll ship to sydney, but the website has their email, and they are just a supplier for barnes (who make the product) so you should be able to find it somewhere.

As far as resins go, this is pretty excellent, though BLACKHAND might want to lend some wisdom too. Nice and easy to use, specifically intended for miniatures, however very quick drying, so little work time!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 15:05:48

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Lady of the Lake

|

Thanks

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 15:19:04

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

No worries. A good thing about this material is that there is no mould release needed, as the pinkysil is still flexible once set.

BLACKHAND: any news on the two-parts? I'm attempting another storm shield mould now (didn't mix up last batch properly and it hasn't set completely firm)

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 16:51:28

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

[SWAP SHOP MOD]

Decrepit Dakkanaut

OH-I Wanna get out of here

|

I'd email Barnes themself n0t, I did and they are very responsive.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/04 17:02:03

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

whalemusic360 wrote:I'd email Barnes themself n0t, I did and they are very responsive.

Exactly.  Craft suppliers are usually very responsive due to the small number of customers they serve, and most will suggest local suppliers.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/05 20:43:27

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Boosting Space Marine Biker

|

Thanks for the tutorial its just what i was looking for

|

COVER IS FOR THE WEAK |

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/05 21:00:13

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

@captain klaw - I will be attemptning a two part mold at some point with my 40k skaven army but am only in the early design stages. When I do I will post up pics for sure, in the meantime keep posting your pics man!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/06 03:07:53

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

If you're lucky I might be able to post up some picks of my storm shield mould and some casts. They've been pretty successful actually! Automatically Appended Next Post: As said, here are some pics of my storm shield 2-part mould and one of the test casts.

Here's the mould in progress. I made a basic square box out of lego (not legos, but lego. Think sheep logic.) then filled the base with a bit of paper clay, although anything clay-like will do. This is just to create a basic form for the mould. I then got a layer of glad-wrap (cling film) and pressed it into the mould and then placed the storm shield and pressed it into the clay. This was so I didn't end up with any residue from the clay on the mould.

Then I poured in a batch of Pinkysil and let it set.

Once dried, I inverted it, removed the clay, added some mould channels with bits of sprue glued to the edges of the shield and poured the 2nd batch of pinkisyl in.

I thought I wouldn't need a release agent, but the first half of the mould hadn't completely dried when I poured the 2nd batch in, and they stuck together  .

So with a few careful cuts with a knife I separated the 2 halves.

Here's the finished halves with my test cast.

TIP: Note the number of input channels at the top of the mould: I used three, and poured into the outer ones, which filled the mould from the base up. This meant that the central hole at the top could vent the bubbles that formed.

The cleaned up cast, with some bubbles to be filled with greenstuff.

I wanted my terminators to have the larger shields so sculpted off the details for the base cast, and am going to gs some individual details later

|

|

This message was edited 1 time. Last update was at 2010/08/06 05:16:54

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/06 08:22:41

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

And so the Apprentice has surpassed the Master....

....just please don't kill me and take over my evil empire (I've spent ages on it  )

Nice work Klaw, the cast was came out really clean and the glad wrap was a nice touch.

TBH I am far lazier and usually pour the rubber in one go then cut down both sides and along the top to free the master copy, leaving the base in one piece to keep the two sides lined up. This method works best with basic shapes but I have a feeling your two part mold method is better for more complicated pieces.

Thanks for posting your pics, I'm thinking I may have to change the name of the thread to reflect the more general casting info it has now.

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/06 08:35:01

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

Haha don't worry I'm under no disillusions about surpassing you. I'm just replicating what I've seen you do.

Pretty happy with the way the casting's been going, my brother seems to think I'll be starting up a forge-world rival or something, despite me only having done some shoulder pads and storm shields.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/06 16:15:37

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Morphing Obliterator

|

BLACKHAND wrote:

TBH I am far lazier and usually pour the rubber in one go then cut down both sides and along the top to free the master copy, leaving the base in one piece to keep the two sides lined up. This method works best with basic shapes but I have a feeling your two part mold method is better for more complicated pieces.

I did mine this way. I find it easier and less steps but you have to be careful on the cut line. My rubber takes 6 hours to cure so its better for me to do it in 1 pour

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/14 21:23:45

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Grisly Ghost Ark Driver

|

Do you think this would work for heads? for LEGS maybe????

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/14 21:33:54

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

@ironfrontalex - With the products that I use you can definitely do heads and legs, It can be complicated but doing legs but with planning it is doable and well worth it to get custom armour and uniforms. If you are just wanting more assault marine legs or something like that I would jsu t buy them and save a bit of work but for a custom army it is just the thing.

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/14 21:49:43

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Tzeentch Aspiring Sorcerer Riding a Disc

|

Good going. Realy nice work

Got some good tutorials on you tube, for this sort of thing. Thinking of trying it myself.

|

|

This message was edited 1 time. Last update was at 2010/08/14 21:50:42

Its hard to be awesome, when your playing with little plastic men.

Welcome to Fantasy 40k

If you think your important, in the great scheme of things. Do the water test.

Put your hands in a bucket of warm water,

then pull them out fast. The size of the hole shows how important you are.

I think we should roll some dice, to see if we should roll some dice, To decide if all this dice rolling is good for the game.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/15 09:42:26

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

BLACKHAND wrote:@ironfrontalex - With the products that I use you can definitely do heads and legs, It can be complicated but doing legs but with planning it is doable and well worth it to get custom armour and uniforms. If you are just wanting more assault marine legs or something like that I would jsu t buy them and save a bit of work but for a custom army it is just the thing.

I've personally just tried it with some corvus heads as a little experiment, and with the Pinkysil it works great.

Instead of gluing the shoulderpad to the plasticard at the base of your mould, shave off the bottom of the neck attachment a little bit so it's flat and glue that to the base.

This is just so that there is a proper vent for the resin to flow in.

Any bubbles that might occur are usually covered up in any case as they are at the glue point when you assemble the model.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/15 10:27:47

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Cheers for the tips Captain Klaw, I haven't quite got to casting heads yet, haven't found a head that I like enough to cast I suppose

If you guys want to post pics of the process you used for casting heads up here I'm sure the other readers would appreciate it!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/17 16:42:28

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Thunderhawk Pilot Dropping From Orbit

|

A little help from our very own dakka. Found this in the Article section, thought I'd re-post it here for anyone that may have missed it.

http://www.dakkadakka.com/wiki/en/Simple%20Two-Piece%20Mold%20for%20Casting%20with%20Resin

|

No trees were hurt in the making of this sig, however many electrons were disturbed.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/17 20:41:31

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Thanks Lennysmash, It's a nice tutorial lots of clear pictures...and they use lego!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/17 21:48:33

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Grisly Ghost Ark Driver

|

Leg would be complicated? has anyone ever tried before?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/18 00:27:25

Subject: Re:BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Apprehensive Inquisitorial Apprentice

|

Hi guys, im based in the UK, and having read this tut, I've been inspired to start making my own should pads, and maybe other bits too (too start though i've gotta get good with green stuff =p) I've been frantically searching around the web looking for suppliers of resin... before i realised i haven't really got a clue what I was looking for, although i have found a site which seems to sell casting materials including resin and silicone.

So I was wondering if i where to put a link to said site, if anyone could look through and point out a decent product (ill post a link directly to the casting section for free =D)

http://www.modelshop.co.uk/category/Cast___Mould,l.html

thank you in advance, and hope it helps other people in the UK find a source for resin and other such things

|

|

This message was edited 1 time. Last update was at 2010/08/18 01:58:29

PS3 fanboy: jesus owns a ps3.

XBOX 360 fanboy: So does Satan. Thor and Odin own 360s though.

Jesus promises the end of evil, Thor promised the end of Ice Giants.

I DON'T SEE MANY ICE GIANTS AROUND. |

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/18 15:52:58

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

IronfrontAlex wrote:Leg would be complicated? has anyone ever tried before?

I thought about it for a while, But decided against it, as two-part moulds are far harder to pull off than simple pour-in one part moulds.

I guess you could attempt it by gluing the feet to the base plasticard which would act as the top vents, and cut between the legs in the mould with a hobby knife to ease in pouring and importantly allow you to remove them.

However as you can see this is getting slightly complicated.

Automatically Appended Next Post: protomane0 wrote:Hi guys, im based in the UK, and having read this tut, I've been inspired to start making my own should pads, and maybe other bits too (too start though i've gotta get good with green stuff =p) I've been frantically searching around the web looking for suppliers of resin... before i realised i haven't really got a clue what I was looking for, although i have found a site which seems to sell casting materials including resin and silicone.

So I was wondering if i where to put a link to said site, if anyone could look through and point out a decent product (ill post a link directly to the casting section for free =D)

http://www.modelshop.co.uk/category/Cast___Mould,l.html

thank you in advance, and hope it helps other people in the UK find a source for resin and other such things

I took a quick look, and they have a very extensive range with a large price range to boot.

Personally, I would suggest emailing the supplier.

I have found suppliers to be more than pleasant and very helpful and straightforward. Just tell them the types of casting/ moulding you wish to do, ask about viscosity (related to the detail you want), flexibility once dried, curing and working times etc.

They should point you in the right direction!

Hope I helped

|

|

This message was edited 1 time. Last update was at 2010/08/18 15:57:45

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/18 19:56:56

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

What Captain Klaw said!

I started out with no knowledge of the products and without an email and subsequent phone call to the retailer I would have ended up with the wrong thing. The supplier will probably have sold these products to modellers before and will have the knowledge to help.

Would really appreciate it if you could post any info you get from the supplier as to what people in the UK could use to do their own resin casting. So far we have details of similar products to the one I use in Australia and the US posted up and it would be great to have a supplier in the UK posted as well!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/19 07:54:01

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

BLACKHAND wrote:What Captain Klaw said!

I started out with no knowledge of the products and without an email and subsequent phone call to the retailer I would have ended up with the wrong thing. The supplier will probably have sold these products to modellers before and will have the knowledge to help.

Would really appreciate it if you could post any info you get from the supplier as to what people in the UK could use to do their own resin casting. So far we have details of similar products to the one I use in Australia and the US posted up and it would be great to have a supplier in the UK posted as well!

Agreed: In time this thread might need a name change too. Maybe BLACKHAND'S Comprehensive Casting Tutorial.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/19 11:12:20

Subject: Re:BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Slippery Scout Biker

|

I always wondered how some did their shoulder pads. This helps a ton as I'm thinking of dumping a lot of time and money into my next marine chapter and don't like a lot of the metal ones GW makes.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/21 03:10:20

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

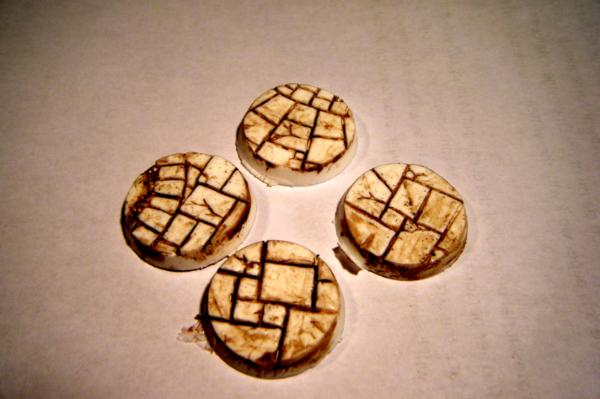

Thought I would post up some pics of the process I m using for some custom bases I sculpted up for my skaven

Pretty similar process to the shoulderpads, its handy that the bases have a big flat area on the bottom as its easy to pour into  The last pic is of the cast bases with a wash of devlan mud to bring out the details. The main issues I ran into were bubbles as usual, I painted on a layer of silicon to begin with, but bubbles still formed and mean I have had to do a bit of clean up around the edges with GS but hey thems the breaks.

Hope this helps someone out there, or inspires someone to try custom bases..they look damn nice with my rats on em!

Cheers

BLACKHAND

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/21 05:31:21

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Water-Caste Negotiator

|

I love pinkysil. Many thanks for bringing it to my attention. Again.

My terminators are almost all assembled complete with cast storm shields: I'll throw some images up if I can.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/21 06:45:14

Subject: Re:BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Annoyed Blood Angel Devastator

|

Right handed dreadnought CCW here I come.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/21 12:31:36

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Decrepit Dakkanaut

|

Now THAT.... is something I've been contemplating for a long, time. Think I have an approach to make it, even bought the parts... but it's a ways down on the priority list.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/08/23 16:59:31

Subject: BLACKHAND'S Shoulderpad Casting Tutorial

|

|

Thunderhawk Pilot Dropping From Orbit

|

Came across this in my research, thought it might benefit someone.

http://www.youtube.com/watch?v=LSH19G_6Yeo&feature=related

|

No trees were hurt in the making of this sig, however many electrons were disturbed.

|

|

|

|

|

|

|