| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 09:17:59

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

It's a different product, the easycast I use is white not clear. I do have a clear resin from the same suppliers but it cured all right, after 2 days!

I'm pretty sure I have used Smooth Cast a few years back and I had a lot of success with it so if you are in the states it is definitely a good option.

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 10:06:05

Subject: Re:BLACKHAND'S General Casting Tutorial

|

|

Scouting Shadow Warrior

|

Thanks alot for the tips!!!

|

I am White/Black

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 10:16:32

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

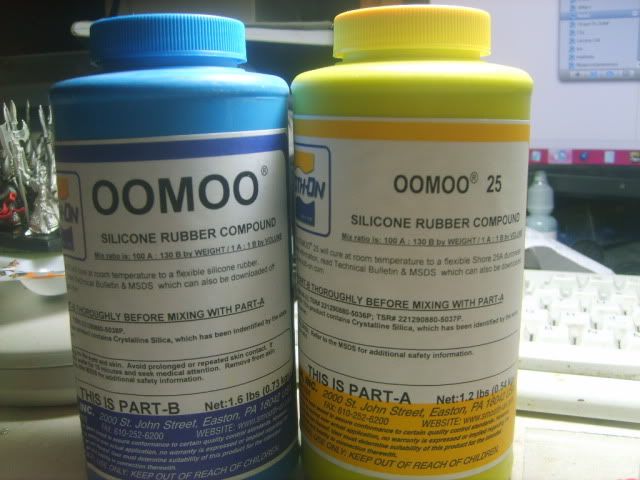

Got a new batch of Oomoo in today, but none of my projects can be posted here. Someone send me something original to do a 2 part mold tutorial on.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 10:32:12

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

LOL, if I wasn't so far away I would definitely do it!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 14:06:08

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

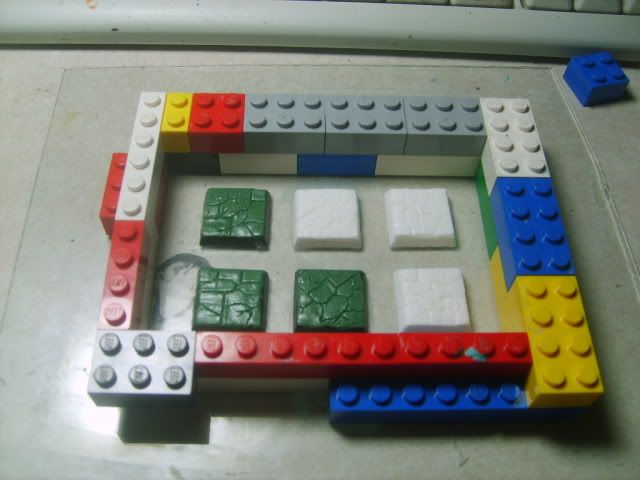

Today I'm doing the second part of my custom base mold, which is taking a set of pulls from my original mold of 3 and using them with the masters to make a mold of 6 bases.

This is beneficial in 2 ways:

1st you can now cast up to 9 at a time instead of just 3.

2nd you can save your master mold to make future pulls to make subsequent molds from. The more you cast resin, the more compounds are leeched from the silicone and eventually the mold needs to be replaced.

I also recommend using a higher quality silicone for master molds such as the one I did last week using GE RTV662a which is a 10:1 rubber. It has a VERY high strength and thus doesn't flex nearly as much as Oomoo 25.

I'll get pics up in a few hours, just waiting for this mold to cure.

Automatically Appended Next Post:

So today I made my expanded mold for my ruined flagstone bases. I used Oomoo 25 which

is a 1:1 RTV silicone.

As always I glued my masters down onto glass.

I then made my form around it with Legos. Sidenote: this mold is the same size as the

original mold, but has twice as many bases on it.

I used Alumilite Rubber to Rubber mold release, which technically isn't for this application,

but I find it works just as well. Mold release is more or less low viscosity grease and will

make your masters look wet.

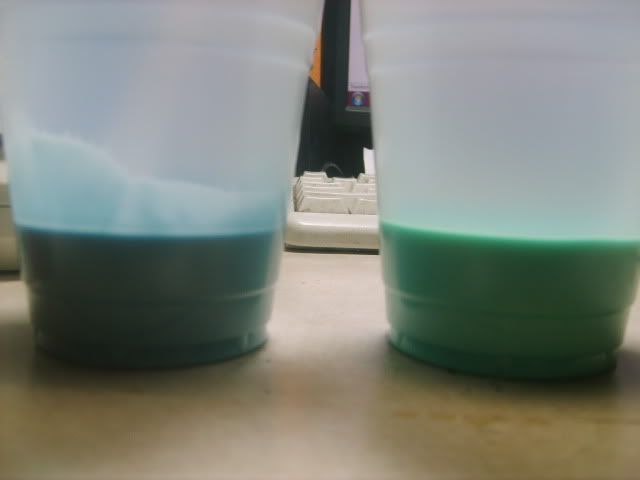

After my form was ready and glued in place, I mixed up my silicone by eyeballing it.

For best results, mix by pouring one into the others cup. Mix as well as you can, then pour

the silicone out into the other cup. This is to help the unmixed parts on the side of the cups

get mixed in and helps with the overall strength of your mold.

Once you are ready to pour, pound the cup on your desk for a few minutes to force out as

many bubbles as possible. Oomoo 25 has a 15 minute pot life, which is plenty long enough to

get bubbles out before it cures in the cup.

Now we are ready to pour. I hold the cup about 10-12 inches above the form and only let a

very thin stream of silicone touch down in a corner of the form. We want the silicone to

cover itself over the masters, and to prevent bubbles we never pour directly onto the pieces.

The reason we use a thin stream is to continue breaking apart bubbles as they fall. The silicone

stretches and the bubbles are forced to pop.

The silicone will naturally settle itself level as long as it's on a level surface. Oomoo 25 has a 75

minute demold time, so to err on the side of caution I gave mine 3 hours to cure before using

it.

Once everything is cured, pull the mold off the glass, pull out the masters, and mix up some

resin. With resin you don't need to go from one cup to the other as it is generally thin enough

to not need such rigorous mixing. My Smooth Cast 300 only has a 2 minute pot life, so I have

to work fast, and any mistakes are likely going to be a miscast.

Here's both molds from this past week together.

And a finished tile.

This was a learning experience as I forgot to wash it off before priming.

If you don't wash the parts in soapy water then paint will slide right off after a little bit of

handling.

Now that I can make enough at one time, I'll be offering these bases in sets of 5. I am still

sculpting the 25x50mm bases. If I get a big enough order I'll do other sizes as well. $.50 per

base is what I'm thinking at the moment. Perhaps a wee discount with larger orders.

|

|

This message was edited 2 times. Last update was at 2010/09/12 18:08:54

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 20:29:48

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Fantastic Aerethan! Thanks for another great tutorial, OOMOO looks like a great product, 3 hours is a decent demold time for a silicone.

Hope you get some orders for your bases!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 0032/09/12 22:12:05

Subject: BLACKHAND'S General Casting Tutorial

|

|

Decrepit Dakkanaut

|

Wow, that's really cool aerethan, thanks for taking the time... and really neat tiles!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/12 22:32:04

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

As soon as I find something worthy of my time that I'm allowed to post(meaning not illegal) I'll put a 2 part mold tutorial up.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/14 13:06:02

Subject: BLACKHAND'S General Casting Tutorial

|

|

Guard Heavy Weapon Crewman

|

This is a great little bit. A long time ago i cast up some of my own bases, craters and armour bits for tanks using Silicon from a little (now closed hobbyshop) and Car body work repair resin id bought from Halfords.

That resin got very hot and in the end damaged the moulds. Does the stuff you recommend get hot as it sets ?

You reckon you can get the stuff to do this from Hobbycraft ? as a new one has opened up in Aberdeen.

Also for bigger terrain pieces could a bigger version of these moulds work with say Plaster? or maybe even modelling Clay ?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/14 13:27:34

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

Clay wouldn't likely work. Plaster would work quite well. I refer you to www.hirstarts.com for plaster technique. His molds are far superior to anything I'm making as well.

All resin will cause some heat when mixed and curing. Large pieces of resin will have much higher temperatures. Slower cure times may help with this although I am not 100% sure.

For larger pieces I'd recommend using plaster despite the weight issue.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/14 13:30:27

Subject: BLACKHAND'S General Casting Tutorial

|

|

Thunderhawk Pilot Dropping From Orbit

|

For bigger pieces I would probably pour in sections with resin as it adheres to itself well from what I gather. Depending on the size and application of the piece though I don't see why you couldn't use plaster or clay, though I'm not sure what the times for it curing/going off would be.

|

No trees were hurt in the making of this sig, however many electrons were disturbed.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/14 13:48:26

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

Clay is too thick to be very useful at casting, and it would be too brittle in such small items. Gypsum Plaster is what you want.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/16 01:07:28

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

@DaHedd: Speaking on behalf of BLACKHAND and myself, as we both use the same products, the heat issues are negligible.

As you could find we use Pinkysil for moulds and Easycast for the actual pours.

I have noticed with some deeper pours like the bases there can be a bit of heat generated, although it does not warp the pinysil as it either does not expand enough or expands at a contained rate with heat.

In any case the heat is not enough to cause problems with pours of less than 5mm thick. Haven't tried any thicker.

Klaw

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/16 01:19:42

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

I personally pour the resin themn sit a heat lamp about 5cm away and heat up the resin, it make sit cure faster!

I have yet to notice any degradation in the pinkasyil moulds but over time I gues I will find out.

Nothing like a 5 minute demould time for a resin addict

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/16 05:22:20

Subject: Re:BLACKHAND'S General Casting Tutorial

|

|

Rifleman Grey Knight Venerable Dreadnought

Realm of Hobby

|

Thanks. This has been very insightful.

|

MikZor wrote:

We can't help that american D&D is pretty much daily life for us (Aussies)

Walking to shops, "i'll take a short cut through this bush", random encounter! Lizard with no legs.....

I kid  Since i avoid bushlands that is

But we're not that bad... are we?

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/16 09:12:48

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

How I love the speed of pinkysil and easycast. I'd rather greenstuff a piece, mould it, cast it, then see if it's any good rather than wait for greenstuff to cure.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/16 09:27:06

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Lol, patience Klaw! I know what you mean though, I have sped through many a casting in a night.

I am currently working on yet another shoulderpad and chest piece combo for my Sabre Legion Terminators so I will try and remember to take pics and post em up....

...and as soon as a little project arrives at a friend's house and he posts pics of the finished product up here on his painting blog I will be able to post pics of the casting process for that.

Wow I'm not sure if that last bit made a lot of sense but you'll get the idea.

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/19 06:07:20

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

Looking forward to it. With....patience.

|

|

This message was edited 1 time. Last update was at 2010/09/19 06:07:45

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 00:55:43

Subject: BLACKHAND'S General Casting Tutorial

|

|

[SWAP SHOP MOD]

Decrepit Dakkanaut

OH-I Wanna get out of here

|

Just poured my first mold. I however completely forgot to spray it with release agent, so not sure how its going to come out.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 01:04:31

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Depending on the product you should be fine, next time spray or use talcum powder!

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 04:33:37

Subject: BLACKHAND'S General Casting Tutorial

|

|

[SWAP SHOP MOD]

Decrepit Dakkanaut

OH-I Wanna get out of here

|

It came off the plastic bits fine, but stuck to the Plexiglas I used as the foundation.

Question for you casting vets. How do I prevent the bubble inside the shoulder pads? I couldn't get a tooth pick in there. I don't think it will ruin anything, as I can just cut the resin out when cast.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 04:40:11

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

talcum powder or degassing.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 04:54:45

Subject: BLACKHAND'S General Casting Tutorial

|

|

Trustworthy Shas'vre

|

Edit: nothing new to add

|

|

This message was edited 1 time. Last update was at 2010/09/22 05:02:52

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 05:08:01

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

Does talcum powder work with pinkysil?

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 06:45:43

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

@Captain Klaw - yep talcum works, usually don't need it though

@whalemusic - Can you post some pics of your mould so we can get an idea of your setup?

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 07:39:53

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

Sorry, should have specified: does it help in reducing bubbles? With pinkysil moulds it isn't such a problem as you can manipulate them when you pour the resin to get some bubbles out, but still there is a high rate of miscasts in shoulderpads due to bubbles...

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 08:58:19

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

If you are miscasting it may be due to how fast you are filling the mold and if you are flexing it while you pour.

Also the type of resin you are using can make a difference. Smooth Cast 300 is self degassing, so as it sets the bubbles make their way to the top. The only trouble I have is with very fine detail molds which I'm hoping to remedy with my longer cure time resin.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 10:56:30

Subject: BLACKHAND'S General Casting Tutorial

|

|

Nurgle Chosen Marine on a Palanquin

|

Sorry guys I don't have too much of a problem any more, I just poke (pretty viciously) into the areas I know will be a problem, the edges of the mould and such, and I get most of the bubbles.

Without seeing how you have set up the mould I can't really give you a good idea how to fix the issue.

|

BobtheInquisitor wrote: BobtheInquisitor wrote:I tend to glue metal models with a combination of BSI cyanoacrylate and my tears of frustration.

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 16:15:03

Subject: BLACKHAND'S General Casting Tutorial

|

|

Water-Caste Negotiator

|

My mould is the same as yours, I think I posted pics earlier. I'm thinking I need some eye-droppers so I can make smaller batches and focus on each pour more without worrying about the resin drying before I can use it.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2010/09/22 17:33:20

Subject: BLACKHAND'S General Casting Tutorial

|

|

Excellent Exalted Champion of Chaos

Lake Forest, California, South Orange County

|

I use 10cc syringes for my 2 part molds. You may want to try those out.

|

"Bryan always said that if the studio ever had to mix with the manufacturing and sales part of the business it would destroy the studio. And I have to say – he wasn’t wrong there! ... It’s become the promotions department of a toy company." -- Rick Priestly

|

|

|

|

|

|

|