| Author |

Message |

|

|

|

|

|

Advert

|

Forum adverts like this one are shown to any user who is not logged in. Join us by filling out a tiny 3 field form and you will get your own, free, dakka user account which gives a good range of benefits to you:

- No adverts like this in the forums anymore.

- Times and dates in your local timezone.

- Full tracking of what you have read so you can skip to your first unread post, easily see what has changed since you last logged in, and easily see what is new at a glance.

- Email notifications for threads you want to watch closely.

- Being a part of the oldest wargaming community on the net.

If you are already a member then feel free to login now. |

|

|

![[Post New]](/s/i/i.gif) 2020/07/13 17:45:20

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

I think the FDM prints are very suitable for using while one figures out exactly what they want to field in an army. Plus it’s great for terrain. I’m getting good results from mine, but then again I’m not a golden demon painter, so blemished minis aren’t terrible for me. Larger model work great though.

Using these at least while you try out a game is better than paying full price and then realizing you need a different set up or hate the game and have wasted the money.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/13 17:46:28

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

PS: since most of the stl escorts were designed for a small size, they are under-detailed. I tried printing one of the more detailed file-rips from the BFG game by Wolfmaskman, but it didn’t turn out well. I contacted some of the guys on FB with resin printers, and neither of them could get it to work, either. Perhaps a smoother ship, like an eldar escort, would work, it my current plan is just to blow up a normal escort and enhance it with plasticard and printed terrain details.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/13 18:16:14

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Thermo-Optical Tuareg

|

I didn't think about scaling up. The cruiser is actually just about the same size as my midsized ships from my Covenant of Antarctica fleet. I think I used those ships as cruisers before, so that seemed about right. I figure if I do a battleship, it should be around the same size as my big Antarctic battleship.

I think the Cruiser I did is based off of Italianmoose's

It's a remix that was supposed to be sliced for better printing. It's not a one-piece build. I printed it in chunks.

The issue I had with my frigates was the prow. It didn't print a good curve on the prow. I split the model in half. Top part is fine, decent curve, bottom part has a jagged prow. Plus, some of the details on the prow are a bit too soft. They'll do for now until I can get resin prints though.

My escort frigate didn't turn out so hot either, but that's because I printed with supports. Every time I use them, I lose detail and get very jagged and visible lines. But again, it'll do for now.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/13 22:08:10

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

Have you tried printing them vertically? We’ve had better results printing some spaceships nose-up in one piece than as several flat pieces.

It sounds like you might also have non-optimal support settings. Before something got changed on our settings, the supports used to come off fairly cleanly, with great detail underneath.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/14 13:58:23

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

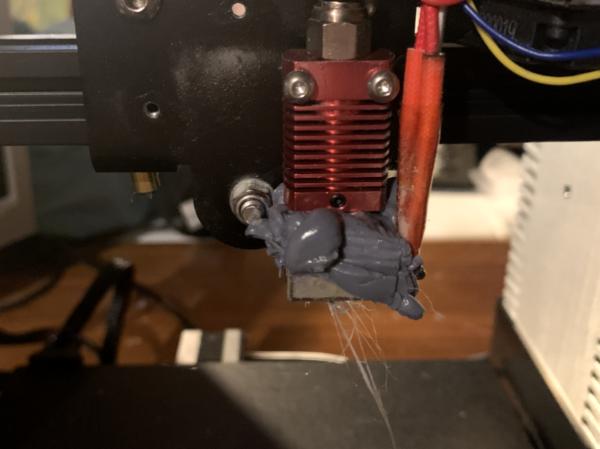

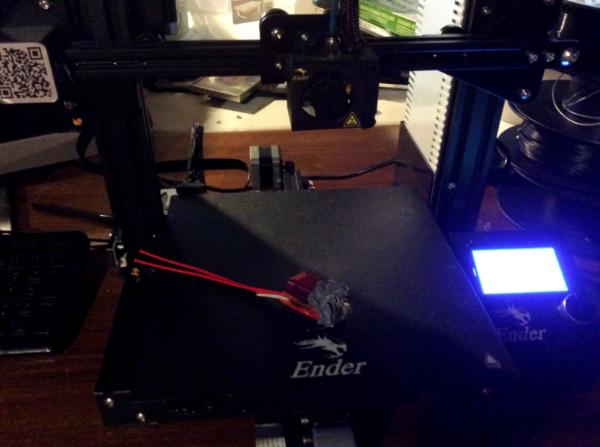

Well, I had an explosion while I was at church. Started a print, got home about 5 hours later to a huge glob of melted pla sliding around on my print bed. Popped it off and saw the gasket had been pushed off and it kept printing above it. Took the fan housing off to see how bad it was.

I think I need a whole new hot endextruder  . Not sure I can even get the connections out. Oh well, off to YouTube to look for solutions.

Edit: Checked Amazon, new parts on order, had 9 minutes and 16seconds to order it and get it tomorrow  . $16.99 and the cable comes with it to go all the way back to the controller, so no worries about the connection.

The glob that was rubbing around the print bed was about 5 times the clump on the extruded shown in the picture.

Not sure, but I had been worried that the stringing was due to a small clog in the nozzle. I almost took it all apart last night but was too tired after being at the hospital all day yesterday. So don’t freak out, but if you are printing constantly like me you may want to take the fan off and a few least inspect around the nozzle. This explosion looks more like there was a gap between the Bowden tube (the tube that channels the PLA down to the nozzle) and the nozzle itself. When you change the nozzles there should be no space between the nozzle and the Bowden tube or material will heat up and clog in that space which leads to insufficient flow. The white Bowden tubes that come with the Enders are not the best quality, and I replaced mine two full spools ago with a high end Bowden tube and better connectors so it does not pop free.

|

|

This message was edited 1 time. Last update was at 2020/07/14 14:10:49

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/14 17:57:40

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Fixture of Dakka

|

Sorry to hear that Theophony.

The dragon on the previous page was exquisite.

Cheers,

CB

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/14 19:48:40

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Calculating Commissar

|

I wonder if that explains some of the issues you've had recently? Replacement parts and upgrades seems to be a good part of the 3d printing hobby

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/14 19:51:51

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Thermo-Optical Tuareg

|

Woof, that's a mess. At least you can fix the problem.

I tried my hand at printing with PETG last night. The stuff requires a higher temperature, but is supposed to be a more resilient material than pla. I have some files for some small action figures I want to print and figured the higher quality material would be good. The results though... not so good. I'm going to have to play with this stuff more and get a handle on it. The test piece needed supports and they melted into the test piece!

I've tried adjusting my settings quite a few times now, and I still can't get a handle on the stringing I get.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/15 18:32:53

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Barzam wrote: Barzam wrote:Woof, that's a mess. At least you can fix the problem.

I tried my hand at printing with PETG last night. The stuff requires a higher temperature, but is supposed to be a more resilient material than pla. I have some files for some small action figures I want to print and figured the higher quality material would be good. The results though... not so good. I'm going to have to play with this stuff more and get a handle on it. The test piece needed supports and they melted into the test piece!

I've tried adjusting my settings quite a few times now, and I still can't get a handle on the stringing I get.

Any luck with the PETG? It sounds like a great product, but I think I’m sticking with my PLA Plus(Pro) for a while.

Also.

You know that feeling you get when you do something you’ve never done before.....lots of nerves...then an “I’ve got this” then.......real excitement.

Got the replacement part in. Quickly saw more wires than I hoped to mess with. Started to trace back to where it all connected and took apart way more screws than I thought I’d need to. Damned if you do, damned if you don’t. Snipped wires, cut cable ties, snaked Wired’s all around. Found that the end connectors were held in by hot glue  . Cut through that waiting to hear the circuit board break. But it’s all back together now.

Even started a print.....

Then quickly stopped as I remembered I probably should level the bed as I’ve flipped the machine over three or four different ways.

Leveled and first print is well on the way and looking fabulous.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/16 15:37:43

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Well  , first print was looking great until about 5 hours in when major electrical storms came through the area and flickered the power a few times in a couple minutes. The Ender is designed to restart where it left off, but with the power fluctuations so quick together I think it just lost memory of where it was. Plus it sat there for another hour with the heat going to the nozzle still. In the end.....another ruined print, and a clogged nozzle. Glad I still have 6 extras laying around, but I might order another dozen soon.

Didn’t realize the nozzle was really clogged at first, but the next few prints would not stick to the heated bed at all. I took the fan off and undid the nozzle. It was restricted, but still allowing material through, but so little was coming through that the pull of the extruded moving was more than the grip onto the bed.

So today’s class lesson is: If the print is not sticking, check your tip for a clog.

Current print is looking fabulous, no strings so far even with gaps between the parts.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/16 21:19:15

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

I think I've really got to grips with the printer now, getting a good feel for what will print well versus what won't. Stringing is mostly gone (on the minis, at least, the supports still get some but that's a non issue really) except for the tiny strands I figure you're always going to get a handful of, and I'm definitely getting an adequate quality level for my purposes (mainly dnd stuff. where even meh minis beat the tokens we normally use) Very pleased with how this Ogre came put, he's definitely my biggest print so far by bulk, though a couple have been taller. Was amazed that his chain came out so neat.  Printed at 0.12 height on his back, took just over 6 hours. Also been taking a brush to some of my prints, again not spectacular work but certainly up to scratch for various DnD hero types. Also a good showcase for my favourite thing about this whole printing malarkey, the freedom to get to some really obscure stuff; Dragonborn and Tieflings you've got some limited options for with stock minis, but Tortles and Firbolgs? There's basically nada on the market, except at mad prices or super hard to get. So yeah, I'm revelling in the freedom to finally add stuff like this to my arsenal for PCs and as a DM.  Also painted up a river troll. Not a mini I'd normally buy on the off chance of needing. but for a few pence of filament and 3.6 hours of printing, iI'll happily add this cheerful chap to the collection.  Onwards and upwards! I'm now at the point where I'm thinking of days in terms of prints rather than hours.... That's good, right? Right???

|

|

This message was edited 1 time. Last update was at 2020/07/16 21:21:14

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/17 00:52:53

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Definitely a plus on number of prints per day instead of hours  .

Ogre looks great. I am leaning more towards printing larger items, like the Necron Heavy stalker I’m doing now. Smaller items risk bad parts. The Dragon empire stuff is coming out good for the most part, but a lot of the bows, spear tips and muskets are breaking because they are so thin.

I’m looking at printing a 27 hour massive building as soon as I change to my new spool. Don’t want to start a huge print and run out of filament  .

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/18 01:57:56

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Just when I thought I was printing something huge and useful.

[youtube] https://www.youtube.com/embed/pxrVEfxrwUw?feature=oembed[/youtube]

A Belgium firm 3D prints a two story home  .

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/18 17:07:40

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

So, back with more samurai type action. All of these are free prints from Thingiverse.

Resized the Chinese dragon to 50mm wide, which isn’t true as it’s the whole print width with his arm sticking out one way and the tail the other, but I think he is a good size now and fits a 50mm square base easy.did I mention I printed two of him out at higher detail. Each print was just under 12 hours. Probably use them in Kings of War 3rd edition as Elven(counts as samurai) war machines.

Also printed lots of other items including open and closed gates and wall sections. Not the greatest print as whoever did the design barrowed another persons design and mashed them together, there is a split at the top of each “long” wall from the failed mash.

Also found .stl files for a lantern (35minutes) and a Taiko Drum (40minutes) to print. The 50mm square bases each took about 30 minutes and it (on the left of the picture) matches the Warlord Games 50mm square base on the right. The Warlord bases are actually thinner, but have tiny nubs on the bottom that bring it to the same height. My prints are just rectangular and fully smooth.

Another Taiko drum on the printer now. Not sure what I’ll print next, probably a half dozen lanterns for fun  .

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/19 00:34:26

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

My latest project: printing out BFG ships in DFC scale. The first attempt was the Sword class frigate, which did not print well. I used a video game rip file by Wolfmaskman on Thingiverse, which was not print-ready. (I talked to a couple guys with resin printers, but they couldn’t get a good print either.). The second is a Cobra Destroyer by Italianmoose. I’m might have to add detail to get it to look right—to the Ravenwing Accessory Sprue reserve!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/19 02:14:52

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Nice  , not a BFG player, but DFC is pulling me strongly.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 13:39:15

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

I am constantly bouncing back and forth between projects, especially with the printer (since I have not painted a lick in weeks  )

Here is a smattering of small quick prints that I’m doing between the larger overnight prints.

Three 4” basic rings I designed in tinkerCAD. 100mx100mmx 2mm tall and 2mm wall thickness. I’ll use them for Bushido as the zones of control markers. I have an 8” version to print, but having issues with my deck level right now on large prints.

Tiny lantern, I’ll need 6 of those for small objectives.

The 60mm base with tree trunk is a print I found online. They fit the woodland scenic 3-4” tree armatures. I’ll print a few and maybe make a cherry blossom orchard from them.

Lastly there’s quite a few rows of Lettuce. Fairly decent prints for speed.the field print did not come out well. I was having issues with the printer last night, but too tired to do anything about it. All the edges curled up and didn’t adhere to the baseplate. Changed the nozzle just Incase it was a clog issue, but that didn’t help. Played with the deck leveling, so far that has helped on smaller prints.

More later, spool almost empty, so lots of small prints to do.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 14:25:23

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Courageous Questing Knight

|

Hey, Theo - all of your pains, I have gone through with my Ender - yes, that huge glob all over the nozzle and into the fan housing is no fun at all.

But, don't be skeerd about eventually going to Resin - so much easier to print, even if the after clean up is a bit more. And, the supports on resin come off so easy, so not much mini clean up.

I am sure you will take the plunge into resin and then you will want to go back and reprint everything you did FDM.

Love your blog - keep it up!!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 15:28:09

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

MDSW wrote: MDSW wrote:Hey, Theo - all of your pains, I have gone through with my Ender - yes, that huge glob all over the nozzle and into the fan housing is no fun at all.

But, don't be skeerd about eventually going to Resin - so much easier to print, even if the after clean up is a bit more. And, the supports on resin come off so easy, so not much mini clean up.

I am sure you will take the plunge into resin and then you will want to go back and reprint everything you did FDM.

Love your blog - keep it up!!

Thanks MDSW,

I am pondering a resin printer, but not for a while. The Ender 3 was to keep me busy while I have been on Furlough due to Covid19, but it’s back to work Monday the 27th, so only a few more days of insane printing freedom.

The next hobby purchase will be models and stuff, and that’s just with birthday cash.

The next really large purchase hobby wise will be a decent computer that I can run a good slicer program on. The Astroprint using cura 3.6.0 is okay for what I have been doing, but doesn’t have key features that full cura and other have, like mirror printing. I’d love to be able to do some mirrored prints just to get twice the models out of a file and look just different enough. The twin dragons I’m going to use for KoW is an example of that.

After that, maybe I’ll jump to resin. Especially since most Patreon files are coming presupported now.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 16:25:26

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

I'm in a similar boat, I do now see a resin printer as an inevitability but it's a much more complex investment, given that the FDM doesn't need anything peripheral beyond the filament, and there are no hazards or other concerns whereas resin you need to worry about gloves,safe storage ect.

I've been more than impressed by the quality you can get out of an Ender 3, but as a painter FDM is something to work around, whereas the resin prints I've painted have just been sublime to paint. I've actually got a massive (11" wingspan!) resin printed dragon coming any day now, I'll be sure to throw some pics of that in here.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 16:35:44

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Paradigm wrote: Paradigm wrote:I'm in a similar boat, I do now see a resin printer as an inevitability but it's a much more complex investment, given that the FDM doesn't need anything peripheral beyond the filament, and there are no hazards or other concerns whereas resin you need to worry about gloves,safe storage ect.

I've been more than impressed by the quality you can get out of an Ender 3, but as a painter FDM is something to work around, whereas the resin prints I've painted have just been sublime to paint. I've actually got a massive (11" wingspan!) resin printed dragon coming any day now, I'll be sure to throw some pics of that in here.

Yeah, the quality of the resin prints are great, so much better than even what we have gotten out of the ender 3, but all the extras. My cats were too curious about the Ender3, I'd worry about the resin.

in the mean time. Tomb sentinel progress. The file doesn't have the weapon arms or a nice tail segment, but body and leg wise its nice.

I did a batch print on body sections while I stayed at my Mom's house to take care of her. The prints came out okay, but as you can see from the furthest left segment they all had a slip on the back. There were servere storms while I was gone, so not sure if it was a power failure/surge, but it looks similar to what happened with the Tianlong Dragon and another print during a power failure.

a few of the segments that top layer just peeled off while cleaning it. The other two parts were each individually printed. you can still see layer lines on the wings, but looks fine to me. Theres a double print of the legs in the background of the first photo . Besides stringing it looks like it came out well.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 16:53:20

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Courageous Questing Knight

|

Failed or sub par prints (on any printer) give me nightmares! And failed prints on FDM printers seem to fail spectacularly!

When painting my FDM printed pieces I would add a bit of glue and flour to the paint and it would help smooth out the lines. Loving your work, Theo!

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/21 17:27:13

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Thermo-Optical Tuareg

|

I've been discouraged about printing this last week or so. Every time I try printing something with supports, it strings like crazy. I need to just sit down and spend an evening doing nothing but string tests, and I really, really don't want to do that.

On the plus side, I found out Vallejo makes the shade of green I use for my Raptors in a spray paint. So, that means I'll be able to work on my multitude of printed vehicles at a much faster pace than if I painted them by hand.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/22 00:58:30

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Barzam wrote: Barzam wrote:I've been discouraged about printing this last week or so. Every time I try printing something with supports, it strings like crazy. I need to just sit down and spend an evening doing nothing but string tests, and I really, really don't want to do that.

On the plus side, I found out Vallejo makes the shade of green I use for my Raptors in a spray paint. So, that means I'll be able to work on my multitude of printed vehicles at a much faster pace than if I painted them by hand.

Good News on the paint front at least.

What sort of printer do you have again? Are the supports from presupported files? Because I have heard not to try those on a FDM printer.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/23 13:53:57

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Courageous Questing Knight

|

I have found every file that comes w/ 'supports' are designed for a resin printer. However, I find doing them myself better, as once you get your preferences dialed in when you hit the auto-support button and maybe add or take away a few, they work flawlessly and you can pull them all right off super easy before you do the final cure. I am sure all resin printer slicers work differently, but the ChiTuBox for Elegoo works great.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/23 17:14:17

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Thermo-Optical Tuareg

|

I have a Flashforge Finder Lite.

The supports I've been printing are the slicer's auto supports. I've only tried printing a pre-supported build once that used resin supports. I know fdm printers can print resin supports. I've seen them do it. But, on the occasion I tried, it didn't work. Too thin, I think.

But yeah, both my auto-generated treelike and linear supports create a ton of strings. Linear supports seem to generally make a mess out of the surface they're attached to, too, but that just seems to be an issue with how the supports attach rather than a settings issue.

I haven't tried much more with the PETG. To be honest, the stuff kind of scares me because the printer has to run significantly hotter than what I usually run it at and having it go at those temps for hours on end, in California triple digit summer doesn't seem like it'd be very good for the printer's long term health. On top of that, the test piece I did used supports. The supports melted into the test piece, making it impossible to remove them. I'm sure with more practice I could get better results though. I think this material may best be suited to short prints that don't require supports.

A curious feature of the PETG though, the slower your print, the more transparent the material. It's weird.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/23 19:09:02

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Is 'Eavy Metal Calling?

|

Barzam wrote: Barzam wrote:I have a Flashforge Finder Lite.

The supports I've been printing are the slicer's auto supports. I've only tried printing a pre-supported build once that used resin supports. I know fdm printers can print resin supports. I've seen them do it. But, on the occasion I tried, it didn't work. Too thin, I think.

But yeah, both my auto-generated treelike and linear supports create a ton of strings. Linear supports seem to generally make a mess out of the surface they're attached to, too, but that just seems to be an issue with how the supports attach rather than a settings issue.

I haven't tried much more with the PETG. To be honest, the stuff kind of scares me because the printer has to run significantly hotter than what I usually run it at and having it go at those temps for hours on end, in California triple digit summer doesn't seem like it'd be very good for the printer's long term health. On top of that, the test piece I did used supports. The supports melted into the test piece, making it impossible to remove them. I'm sure with more practice I could get better results though. I think this material may best be suited to short prints that don't require supports.

A curious feature of the PETG though, the slower your print, the more transparent the material. It's weird.

No experience with the PETG to help with that, but support wise I’ve seen a couple videos and all of them seen to suggest using the zigzag supports over just lines as you won’t have ends, and ends are where the strings start from what I see.

My dialed in settings means that I am unhappy with some of my older prints. So I reprinted the Komainu rider and started throwing some paint.

It takes longer to print, and more prints as this time it’s not a 1 piece model but 5 pieces. Still this and my reprint of the Kirin are gorgeous.

Struggling with color options right now, not sure what color armor should be.

|

LOL, Theo your mind is an amazing place, never change.-camkierhi 9/19/13

I cant believe theo is right.. damn. -comradepanda 9/26/13

None of the strange ideas we had about you involved your sexual orientation..........-Monkeytroll 12/10/13

I'd put you on ignore for that comment, if I could...Alpharius 2/11/14 |

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/24 06:17:02

Subject: 3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

Italianmoose recently uploaded a new Eldar ship, the Sunjammer Tiny Dancer as a tribute to his mother, so I had tro print one out. It's a gorgeous ship. Unfortunately, even at 115% the thin ventral fins did not print. I'll have to try again at a different orientation, and maybe 140%.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/24 06:20:44

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

Forgot to add the photos.

|

|

|

|

|

|

![[Post New]](/s/i/i.gif) 2020/07/24 06:22:25

Subject: Re:3D Printing Blog, Come gather round the printer kids

|

|

Legendary Master of the Chapter

|

It's doing it again!

|

|

|

|

|

|

|

|